Application of nickel-based catalyst in preparation of hydrogen through hydrazine decomposition

A nickel-based catalyst, hydrazine decomposition technology, applied in physical/chemical process catalysts, hydrogen production, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of Al loss, reduced hydrogen production selectivity, etc. Achieve the effect of easy separation, high stability, high catalytic activity and selectivity

Inactive Publication Date: 2016-01-06

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

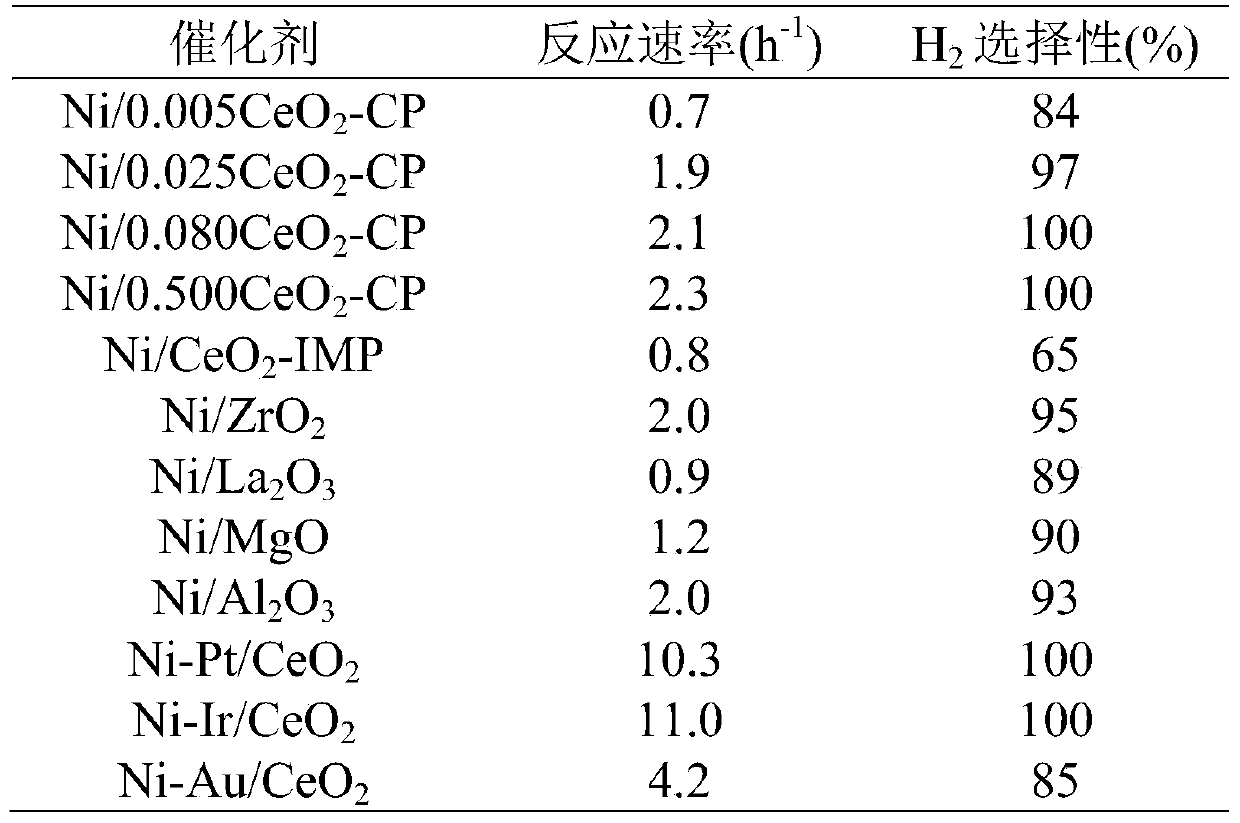

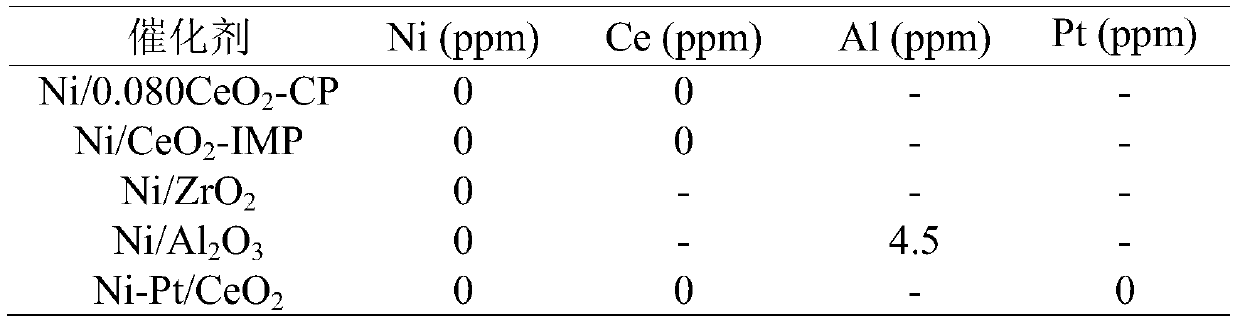

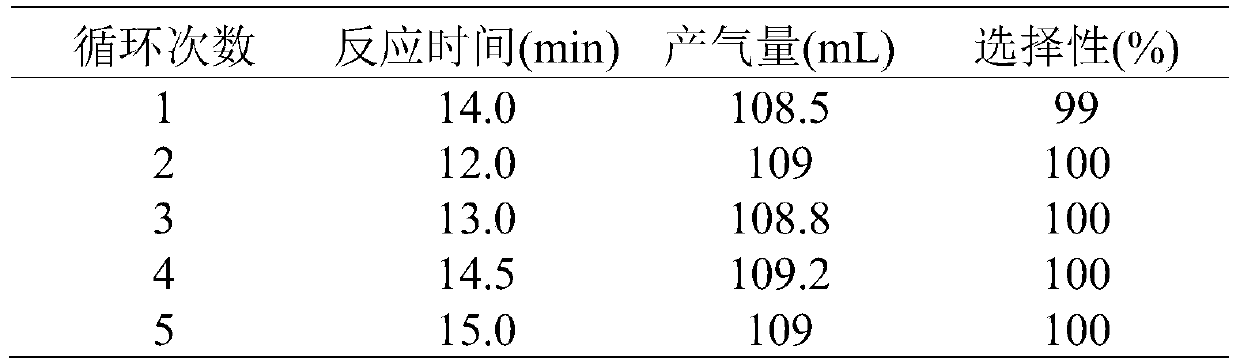

Although the Ni-Al catalyst system has a high selectivity for hydrogen production in the decomposition of hydrazine hydrate, there are still some problems: i) the Al in the catalyst will be lost with multiple cycles of the reaction; ii) with the reaction temperature When it rises above 50°C, the selectivity of hydrogen production will decrease

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an application of a nickel-based catalyst in preparation of hydrogen through hydrazine decomposition, and concretely provides a load-type nickel-based catalyst prepared from nickel-containing mixed hydroxide or carbonate as a precursor. The catalyst is composed of Ni-M / X, wherein M is one or several metal components selected from Co, Fe, Cu, Zn, Rh, Ru, Pd, Pt, Ir, X is a metal oxide, The load capacity of Ni is 5-90wt%. Addition of the metal M is selectable, and X can be a monocomponent oxide or mixed oxides. The catalyst has characteristics of high reaction activity and good selectivity. Hydrazine or hydrazine hydrate can be decomposed rapidly to prepare hydrogen under action of the catalyst in a condition of 0-100 DEG C, and the selectivity can reach the highest 100%. The catalyst has good stability. Provided is a method for preparing clean hydrogen without CO. The raw materials of the catalyst are easily available, the technology is simple, and the catalyst has good application prospects.

Description

technical field The invention relates to a high-efficiency hydrazine decomposition catalyst for hydrogen production, in particular to the preparation and application of a nickel-based metal catalyst used in the low temperature range to decompose pure hydrazine or hydrazine hydrate to produce hydrogen. Background technique Optimizing the energy structure and developing and utilizing efficient and clean conversion technologies are important ways to solve the energy crisis. Hydrogen is an important clean energy, which has the advantages of wide sources, high energy density, non-toxic and harmless, and the combustion product is only water vapor without any greenhouse gas generation, so it is considered to be a new type of promising alternative to fossil energy. Energy has always been widely concerned all over the world. The storage and transportation of hydrogen has always been the technical bottleneck hindering the development of hydrogen energy. At present, there are two mai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/83B01J23/755B01J23/89C01B3/04

CPCY02E60/36

Inventor 黄延强贺雷张涛王晓东王爱琴

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com