A dense phase gas-solid fluidized bed dry separation system and process

A sorting system and fluidized bed technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of inability to efficiently sort minerals, etc., and achieve easy fluidized bed regulation , Reduce medium circulation, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments in the drawings:

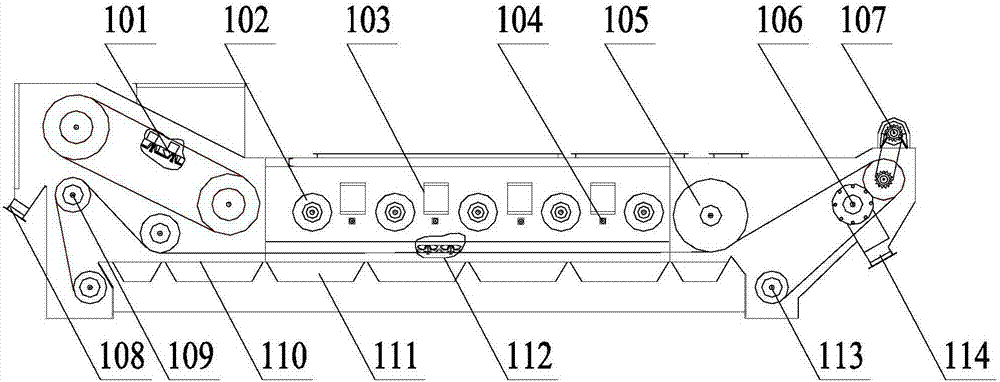

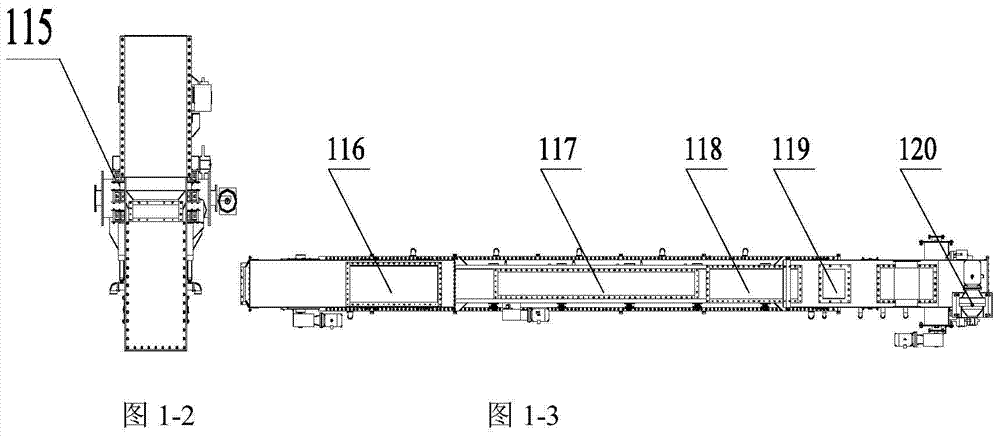

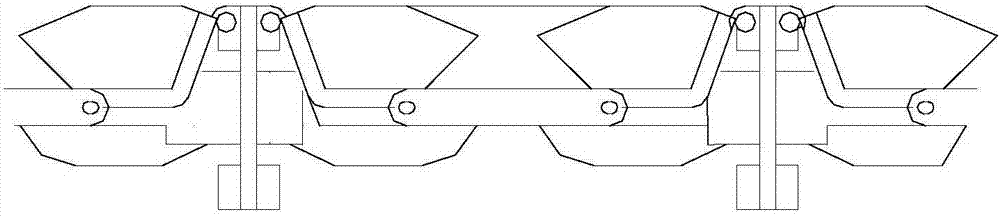

[0045] The dense phase gas-solid fluidized bed dry separation system of the present invention includes a gas-solid fluidized bed dry separation machine, a dust collector, an induced draft fan, a sieving machine, a crusher, and a blower. The gas-solid fluidized bed dry separation system The method sorting machine includes an air distribution device, a floating material discharge device, a sinking material discharge device and a density measuring device; the four devices are installed in the casing of the sorting machine, and the air distribution device is connected to the sorting machine The bottom is installed horizontally. The floating material discharge device is connected to the upper part of the sorting machine. The sinking material discharging device includes a net bag sinking material discharging scraper located at the lower part of the sorting machine. The den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com