Electro-hydraulic proportional control system for mine hydraulic winch

An electro-hydraulic proportional, hydraulic winch technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of poor driving and braking synergy, poor speed regulation stability, low automation level, etc., to avoid system pressure shock, The effect of improving reliability and reducing the cost of retrofitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

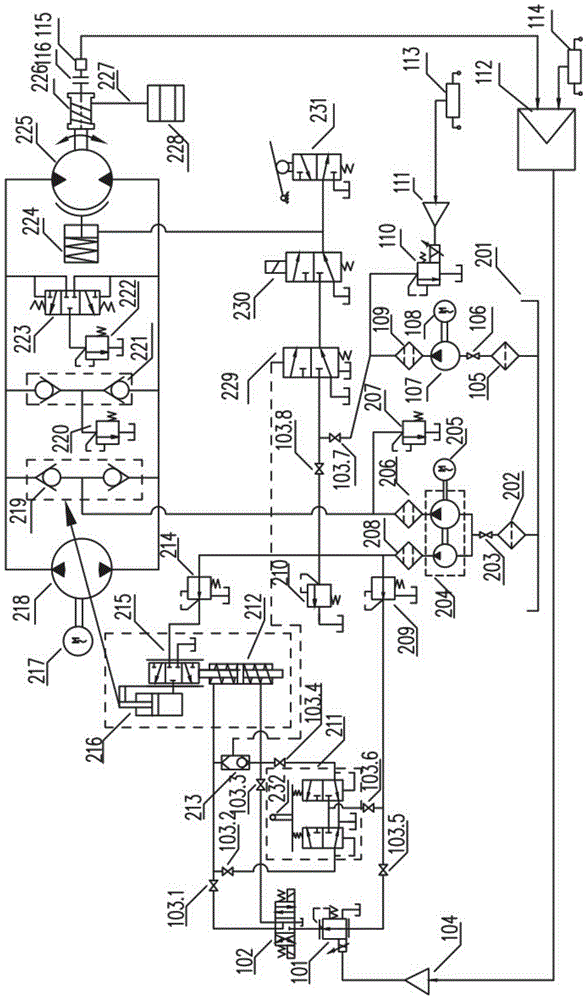

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

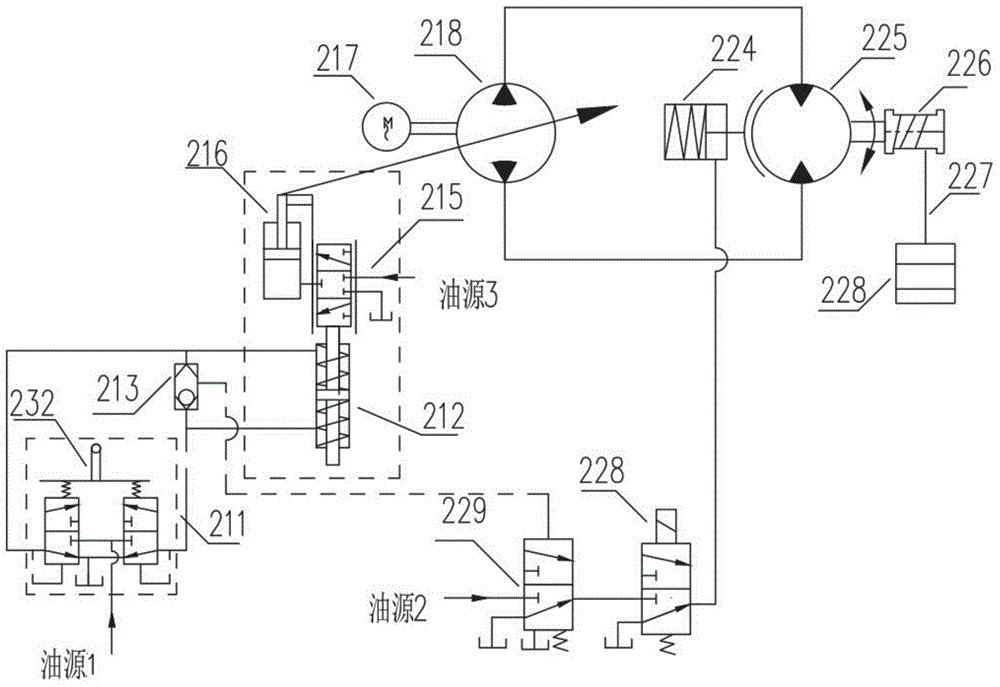

[0029] Such as figure 2 As shown, an electro-hydraulic proportional control system for a hydraulic winch used in an open mine includes an electro-hydraulic proportional drive part and an electro-hydraulic proportional brake part.

[0030] The electro-hydraulic proportional driving part includes a driving pump station, a rotary encoder 115 , a controller 112 , an amplifier 104 , an electro-hydraulic proportional pressure reducing valve 101 , an electromagnetic reversing valve 102 and a driving handle 114 . Wherein, the driving pumping station includes oil tank 201, coarse oil filter 202, stop valve 203, double vane pump 204, auxiliary motor 205, fine oil filter 206 and 208, overflow valve 207 and 210, pressure reducing valve 209 and 214 . The oil inlet end of the coarse oil filter 202 is connected to the tank 201, and its oil outlet is connected to the oil inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com