Organic phase cadmium sulfide/cadmium telluride nanocrystalline superstructure, preparation method and applications

A technology of cadmium sulfide and cadmium telluride, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve problems such as limited application, and achieve the effects of short time, high yield and stable photochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

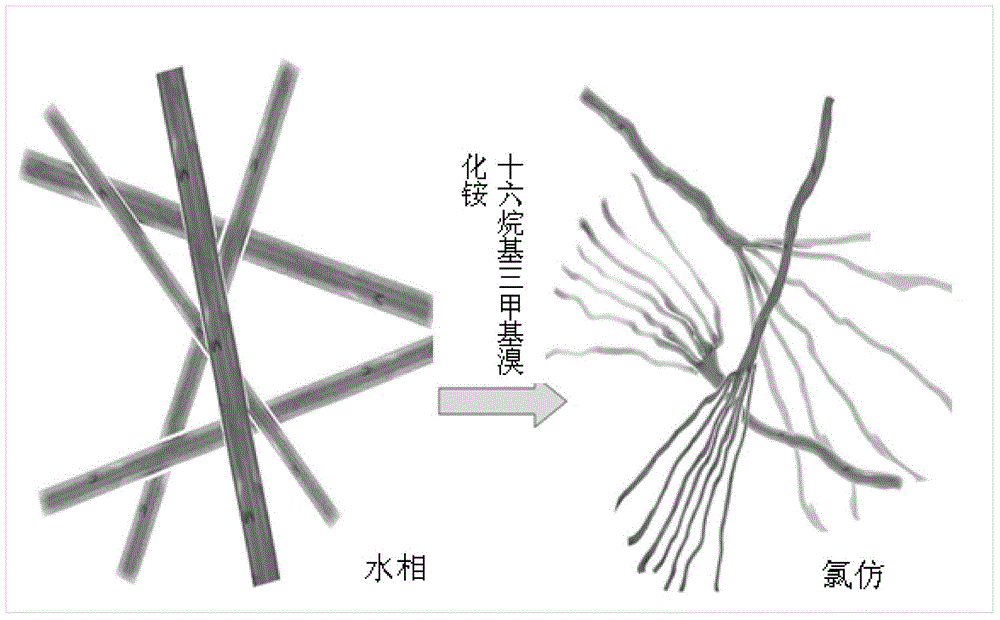

[0031] Dissolve 3.6g of CTAB in 100mL of chloroform, add 4mL of NCsS solution with TGA as a ligand into 4mL of CTAB in chloroform, and let the mixture stand. After 8 h, the solution in the chloroform phase was collected to obtain a soft and loose organic phase NCsS structure; 30 mg of P3HT was dissolved in 3 mL of chloroform. Mix 100 μL of NCsS in chloroform and 200 μL of LP3HT solution to obtain the final solution. Spin coating on the pre-cleaned gold electrode (2000rpm) to prepare a photodetector device, in which the mass ratio of poly 3-hexylthiophene (P3HT) and organic phase cadmium sulfide / cadmium telluride nanocrystalline superstructure is 1.2:3.8.

Embodiment 2

[0033] Dissolve 4.0 g of CTAB in 100 mL of chloroform, add 4 mL of NCsS solution with TGA as a ligand into 4 mL of CTAB in chloroform, and let the mixture stand. After 8 h, the solution in the chloroform phase was collected to obtain a soft and loose organic phase NCsS structure; 40.0 mg of P3HT was dissolved in 3 mL of chloroform. Mix 100 μL of NCsS in chloroform and 200 μL of LP3HT solution to obtain the final solution. Spin coating on the pre-cleaned gold electrode (2000rpm) to prepare a photodetector device, in which the mass ratio of poly 3-hexylthiophene (P3HT) and organic phase cadmium sulfide / cadmium telluride nanocrystalline superstructure is 2:4.

Embodiment 3

[0035] Dissolve 3 g of CTAB in 100 mL of chloroform, add 4 mL of NRsS solution with TGA as a ligand into 4 mL of CTAB in chloroform, and let the mixture stand. After 8 h, the solution in the chloroform phase was collected to obtain a soft and loose organic phase NCsS structure; 30.0 mg of P3HT was dissolved in 3 mL of chloroform. Mix 100 μL of NCsS in chloroform and 200 μL of LP3HT solution to obtain the final solution. Spin coating on the pre-cleaned gold electrode (2000rpm) to prepare a photodetector device, in which the mass ratio of poly 3-hexylthiophene (P3HT) and organic phase cadmium sulfide / cadmium telluride nanocrystalline superstructure is 1:3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com