Method for preparing tea polyphenol/cellulose acetate nanofiber membrane

A technology of cellulose acetate and nanofiber membrane, which is applied in the field of nanomaterials, can solve the problems that there is no composite preparation of nanofibers, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

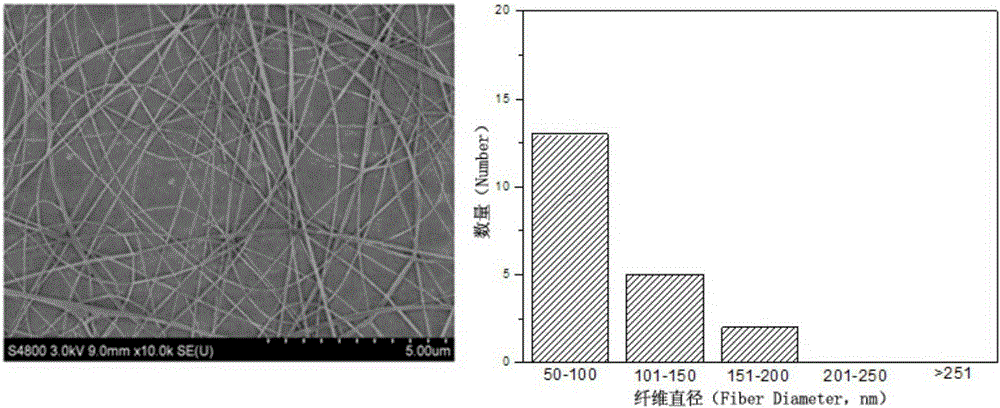

Embodiment 1

[0029] The cellulose acetate and absolute ethanol were placed in a beaker at a mass ratio of 5:8 and sealed, and stirred at room temperature for 20 min by a magnetic stirrer to disperse the cellulose acetate to obtain a mixed solution.

[0030] Put the tea polyphenol powder in N-N dimethylformamide liquid and seal it into an ultrasonic cell pulverizer, and process the mixed solution for 5 minutes in a cyclic pulse working mode.

[0031] Pour the prepared cellulose acetate / absolute ethanol mixture into the tea polyphenol / N-N dimethylformamide solution to prepare a mixed solution with a mass fraction of cellulose acetate of 8%, and put it in a water bath with a magnetic force of 60°C. Stir in a stirring pot for 5 hours until a completely homogeneous and transparent solution is formed.

[0032] Adjust the ambient temperature and humidity in the operating room to ensure that the spinning ambient temperature is 20°C and the relative humidity is within the range of 65%. The prepare...

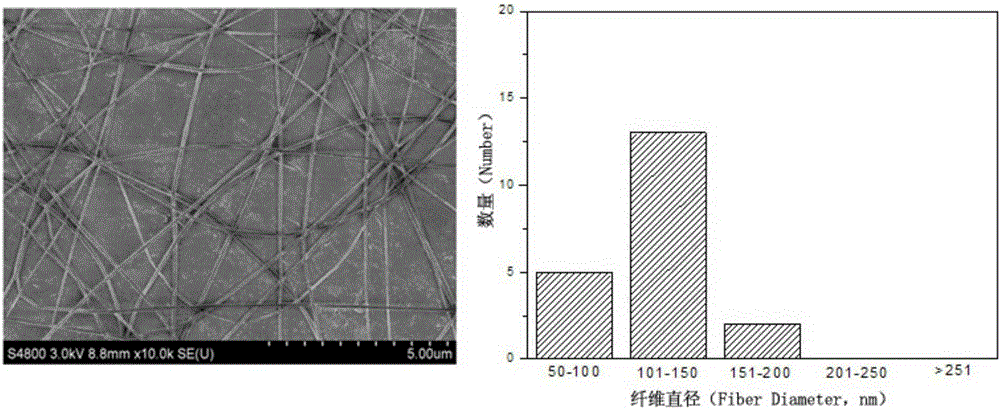

Embodiment 2

[0036] The cellulose acetate and absolute ethanol were placed in a beaker at a mass ratio of 5:8 and sealed, and stirred at room temperature for 20 min by a magnetic stirrer to disperse the cellulose acetate to obtain a mixed solution.

[0037] Put the tea polyphenol powder in N-N dimethylformamide liquid and seal it into an ultrasonic cell pulverizer, and process the mixed solution for 5 minutes in a cyclic pulse working mode.

[0038] Pour the prepared cellulose acetate / absolute ethanol mixture into the tea polyphenol / N-N dimethylformamide solution to prepare a mixed solution with a mass fraction of cellulose acetate of 8%, and put it in a water bath with a magnetic force of 60°C. Stir in a stirring pot for 5 hours until a completely homogeneous and transparent solution is formed.

[0039] Adjust the ambient temperature and humidity in the operating room to ensure that the spinning ambient temperature is 20°C and the relative humidity is within the range of 65%. The prepare...

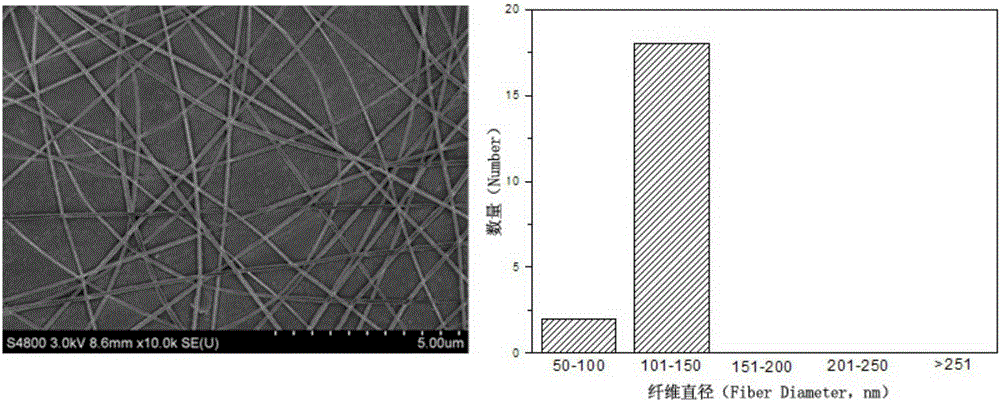

Embodiment 3

[0043] The cellulose acetate and absolute ethanol were placed in a beaker at a mass ratio of 5:8 and sealed, and stirred at room temperature for 20 min by a magnetic stirrer to disperse the cellulose acetate to obtain a mixed solution.

[0044]Put the tea polyphenol powder in the N-N dimethylformamide liquid and seal it into an ultrasonic cell pulverizer, and process the mixed liquid for 5 minutes in a cyclic pulse working mode.

[0045] Pour the prepared cellulose acetate / absolute ethanol mixture into the tea polyphenol / N-N dimethylformamide solution to prepare a mixed solution with a mass fraction of cellulose acetate of 8%, and put it in a water bath with a magnetic force of 60°C. Stir in a stirring pot for 5 hours until a completely homogeneous and transparent solution is formed.

[0046] Adjust the ambient temperature and humidity in the operating room to ensure that the spinning ambient temperature is 20°C and the relative humidity is within the range of 65%. The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com