Evaporative cooling method and equipment with air exhaust function and cooling capacity recovery function

A technology of evaporative cooling and cold energy recovery, applied in the field of evaporative cooling and evaporative air-conditioning system, can solve the problems of small cooling range, high cost, complicated structure of exhaust system, etc., and achieve low engineering cost, compact structure and system structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

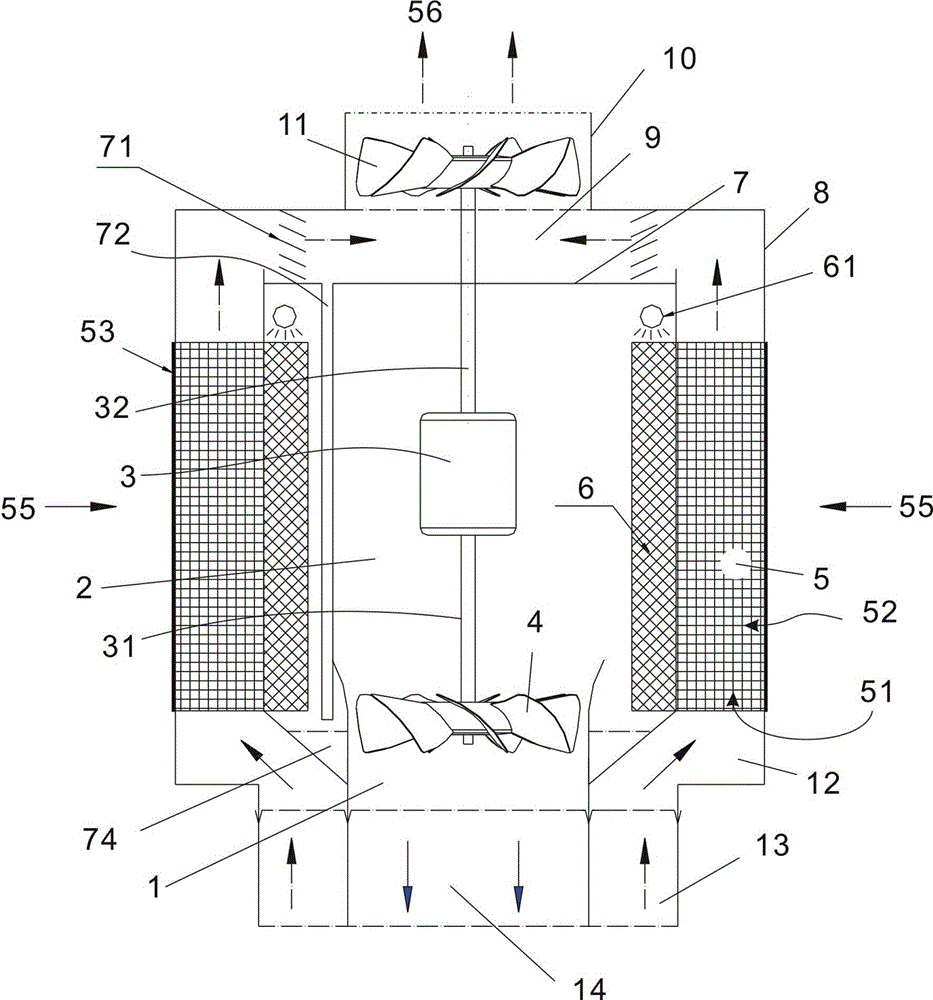

[0062] Combine below figure 1 The preferred embodiments shown further describe the invention in detail.

[0063] Such as figure 1 As shown, implement a method of evaporative cooling with exhaust air and cooling capacity recovery, said method comprises steps:

[0064] S1, first set the air supply chamber 1 and a cold air chamber 2, so that the two are connected;

[0065] S2, then a fan motor 3 is set in the cold air cavity 2, and the fan motor 3 has a front shaft 31 and a rear shaft 32; the end of the front shaft 31 is connected with a fan 4;

[0066] S3, then arrange the air sensible heat exchanger 5 around the cold air chamber 2;

[0067] S4, then on the inner side of the air sensible heat exchanger 5, a filler 6 is set;

[0068] S5, then a partition plate 7 is set on the top of the cold air chamber 2, so that a return air passage 9 is formed between the partition plate 7 and the casing 8;

[0069] S6, then arrange a row of air chambers 10 on the top of the air return du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com