Multi-stage and multi-section combined type chemical engineering high-difficulty wastewater zero-discharge treatment system

A treatment system and composite technology, which is applied in the field of multi-stage multi-stage composite zero-discharge treatment system for difficult chemical wastewater, can solve the problems of high sludge treatment costs in secondary sedimentation tanks, failure to meet national standards, and slow adsorption speed of activated carbon. Simple structure, easy maintenance, and the effect of reducing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

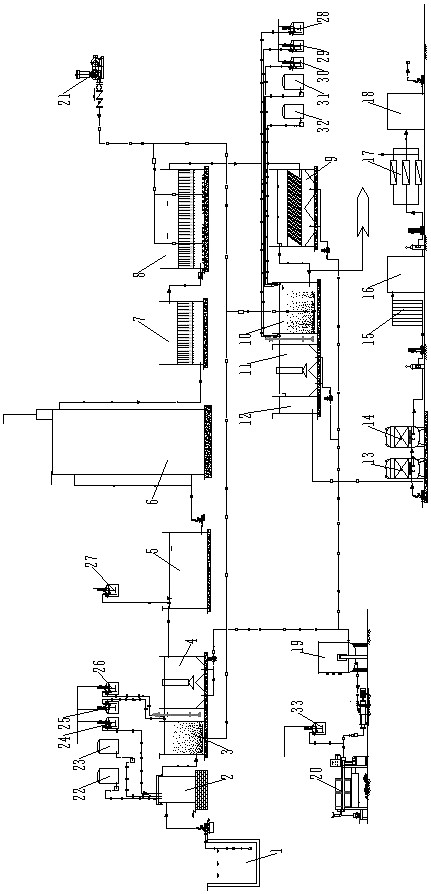

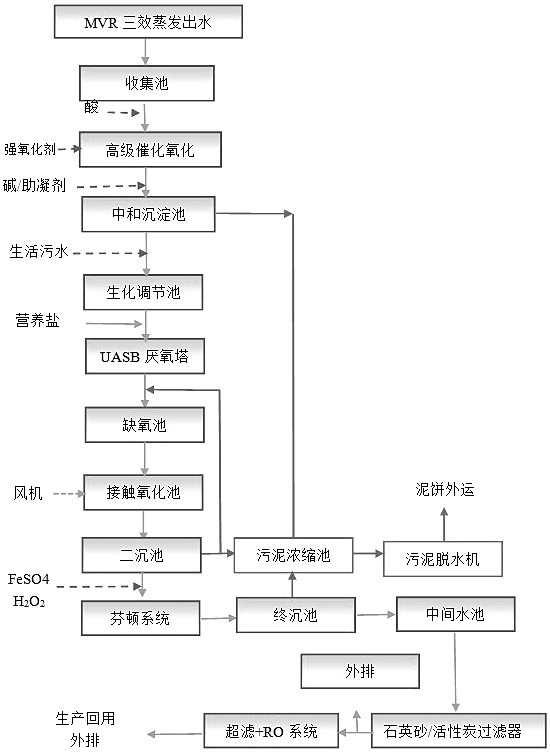

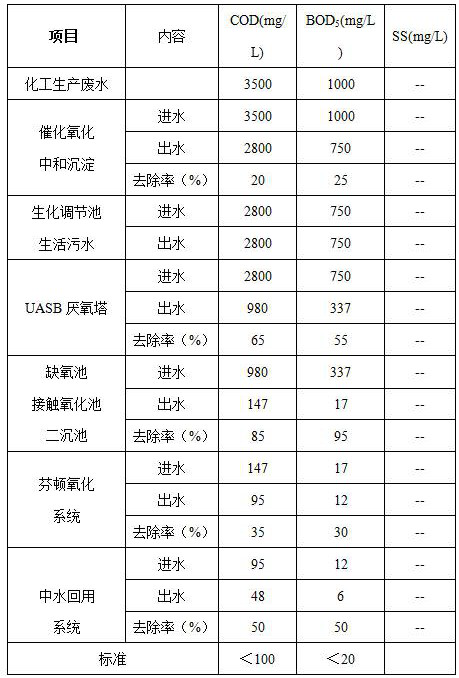

[0027]The technical scheme of the present invention is described in detail in conjunction with the accompanying drawings, a multi-stage and multi-stage composite zero-discharge treatment system for difficult chemical wastewater, including a pretreatment system, a biochemical treatment system, a Fenton oxidation system, a reclaimed water reuse system, and a sludge treatment system , the sump 1 in the pretreatment system is communicated with the advanced catalytic oxidation reactor 2 and the oxidation reaction tank 3 successively through the sewage pipeline, and the oxidation reaction tank 3 is successively communicated with the overflow of the dosing mixing tank 1 and the neutralization sedimentation tank 4, and oxidation The bottom of the reaction tank 3 is provided with an aeration pipe 1, an acid liquid storage tank 122, a hydrogen peroxide storage tank 123 and a ferrous sulfate solution storage tank 124 are respectively communicated with the advanced catalytic oxidation react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com