Polymer irradiation damage test device and test method

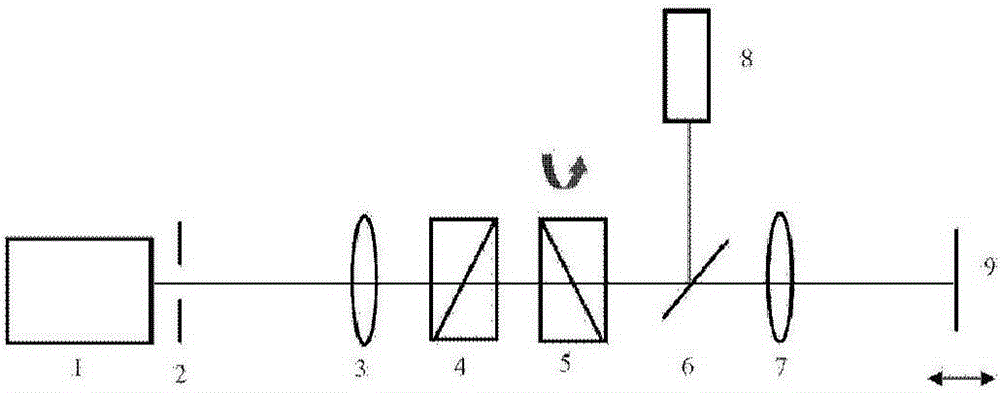

A technology of radiation damage and testing device, applied in the field of material performance testing, can solve the problems of damage threshold error, inability to detect radiation damage in real time, and inability to qualitatively and quantitatively analyze the composition of gas fragments in real time, so as to reduce energy Attenuation and test error, accurately test the effect of irradiation energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

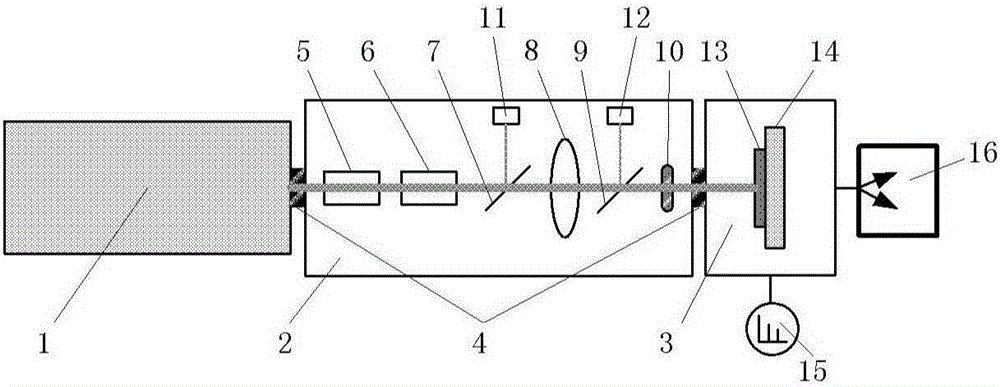

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0019] Such as figure 2 As shown, a test device for polymer radiation damage proposed by the present invention includes three relatively independent chambers, which are respectively a light source chamber 1, an optical path chamber 2 and a sample chamber 3, wherein the optical path chamber 2 and the sample chamber 3 is a vacuum chamber, and the above three chambers are separated by a flange window 4, and the window is CaF 2 The material can pass through the excimer laser, and its transmittance is T 4 ,T 4 Usually above 99.9%.

[0020] The excimer laser light source used for irradiation is accommodated in the described light source chamber 1, and it is used to produce the excimer laser of predetermined wavelength, is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com