A buried oil cooling system for an oil-immersed transformer

An oil-immersed transformer and oil-cooling system technology, applied in the field of transformer cooling, can solve the problems of difficult cleaning, affecting production, reducing equipment life, etc., and achieving the effect of avoiding excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

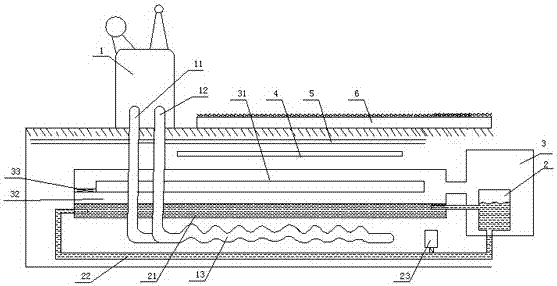

[0036] like figure 1 As shown, the buried oil cooling system of an oil-immersed transformer of the present invention includes a transformer 1 located on the ground and an underground cooling system, the cooling system is located at least one meter below the ground, and the cooling system includes oil cooling Circulation system, water cooling circulation system and air cooling circulation system;

[0037] The oil cooling circulation system includes a cooling oil pipe 13 and an oil pump. The oil pipe communicates with the transformer 1 through the oil pump to form a circulating oil cooling passage; the inlet and outlet of the oil cooling system communicate with the oil inlet 12 and the oil outlet 11 of the transformer 1 respectively. The transformer 1 Both the oil inlet 12 and the oil outlet 11 are located at the bottom or the lower side wall of the transformer 1. The cooling oil pipe 13 is formed to include several cooling branch pipes forming a network. The two ends of the coo...

Embodiment 1

[0045] The installation method of the buried oil cooling system of a kind of oil-immersed transformer in embodiment 1:

[0046] (1) Excavate a deep pit with a length, width and height of 13m*15m*3.5m, fill and compact the bottom of the pit;

[0047] (2), set up a basement on one side of the deep pit, and set up a water tower in the basement;

[0048] (3) Lay a first powder layer with a particle size of less than 10 mesh and a thickness of 3-3.5cm at the bottom of the deep pit, and use a steel pipe with an inner diameter of 3-5cm to build an S-shaped return water above the first powder layer channel, and then lay a second powder layer with a particle size of less than 10 mesh and a thickness of 4-4.5cm above the return channel; spread the second powder layer and use a rammed earth device with a pressure of 100-150kpa to place the second powder layer compaction;

[0049] (4) On the top of the second powder layer, use fine stones with an outer diameter of 1-2.5cm to lay a 15-20...

specific Embodiment 3

[0058] The starting method of the buried oil cooling system of a kind of oil-immersed transformer in embodiment 1 or embodiment 2:

[0059] (1) Start some fans to circulate cold air in the return air passage, air intake passage and basement;

[0060] (2) Start the oil pump to circulate the transformer oil in the cooling oil pipe and transformer;

[0061] (3) When the step-up voltage of the transformer is half of the normal use, wait for the temperature of the transformer oil to rise to its normal use temperature value, and start all the fans;

[0062] (4) When the transformer continues to adjust the gear and boost the voltage to three quarters of the normal use, start some water pumps to make the cooling water circulate among the water inlet channel, return water channel and water tower;

[0063] (5) Adjust the voltage of the transformer to the voltage value for normal use, observe the value of the oil temperature of the transformer; start or close part or all of the water pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com