Method for efficiently treating pig cultivation waste water

A waste water, high-efficiency technology, applied in chemical instruments and methods, animal husbandry wastewater treatment, biological water/sewage treatment, etc., can solve the problems of large maintenance and management, easy pollution of groundwater, and many mechanical equipment, and achieve low energy consumption, The effect of small seasonal influence and less mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

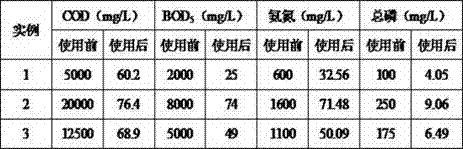

Examples

preparation example Construction

[0020] Preparation of ecological filter cake: according to the mass ratio of 2:3:4, take humic acid, vermiculite and montmorillonite and put them into a ball mill, and conduct ball milling at 400r / min, collect the ball milled material, according to the mass ratio of 5:2~5:4 , use a spray gun to spray the ball mill into the loofah, then put the loofah into the tubular carbonization furnace, set the temperature at 430-470°C, carbonize for 3-5 hours, and collect the carbonized mixture; in parts by weight, take 90 ~100 parts of water, 30~35 parts of carbonized mixture, 10~15 parts of gelatin and 4~6 parts of sucrose fatty acid ester are put into the container, stir evenly, and heat the container to 85~90℃, keep it warm for 2~3 hours Naturally cool to room temperature, filter, collect the filtrate and put it in a 50°C oven to dry for 50-60min, collect the dry matter, and then the ecological filter cake can be obtained.

[0021] Establishment of pig raising wastewater treatment syst...

example 1

[0025] Preparation of ecological filter cake: according to the mass ratio of 2:3:4, put humic acid, vermiculite and montmorillonite into a ball mill, and perform ball milling at 400r / min, collect the ball mill, and use a spray gun to Spray the ball mill into the loofah, then put the loofah into a tubular carbonization furnace, set the temperature at 430°C, carbonize for 3 hours, and collect the carbonized mixture; in parts by weight, take 90 parts of water, 30 parts of carbonized mixture, Put 10 parts of gelatin and 4 parts of sucrose fatty acid ester into a container, stir evenly, heat the container to 85°C, keep it warm for 2 hours, cool it down to room temperature naturally, filter it, collect the filtrate and put it in an oven at 50°C to dry for 50 minutes. The dried matter is collected to obtain an ecological filter cake.

[0026] Establishment of pig raising wastewater treatment system: build a filter tank with a length of 4m, a width of 3m, and a height of 2m. An inlet ...

example 2

[0029] Preparation of ecological filter cake: according to the mass ratio of 2:3:4, put humic acid, vermiculite and montmorillonite into the ball mill, and carry out ball milling at 400r / min, collect the ball mill, press the mass of 5:4, use a spray gun to Spray the ball mill into the loofah, then put the loofah into the tubular carbonization furnace, set the temperature at 470°C, carbonize for 5 hours, and collect the carbonized mixture; in parts by weight, take 100 parts of water, 35 parts of the carbonized mixture, Put 15 parts of gelatin and 6 parts of sucrose fatty acid ester into a container, stir evenly, and heat the container to 90°C, keep it warm for 3 hours, cool it down to room temperature naturally, filter, collect the filtrate, put it in an oven at 50°C, and dry it for 60 minutes. The dried matter is collected to obtain an ecological filter cake.

[0030] Establishment of pig raising wastewater treatment system: build a filter tank with a length of 4m, a width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com