Method for promoting flavor of sauce

A sauce and flavor technology, which is applied in the field of improving the flavor of sauce, can solve the problems of sauce quality impact, sauce flavor damage, etc., and achieve the effects of reasonable proportion, flavor retention and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

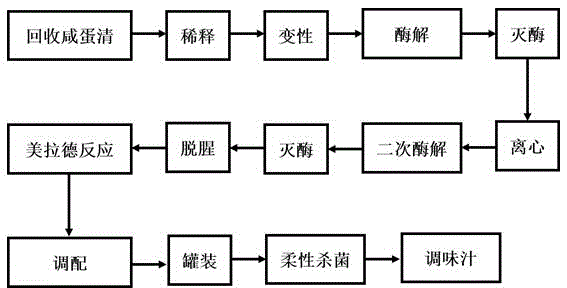

Method used

Image

Examples

Embodiment 1

[0035] (1) Collection of raw materials: recover salted duck egg white to obtain salted duck egg white recovery liquid;

[0036] (2) Dilution: Dilute the salted duck egg white recovered solution obtained in step (1) 5 times with distilled water to obtain a salted egg white dilution;

[0037] (3) Denaturation: Denature the salted egg white dilution obtained in step (2) at 100°C for 10 minutes, and cool;

[0038] (4) Enzyme hydrolysis and enzyme inactivation: adjust the initial pH of the salted egg white dilution to 6.0, add papain at 2% of the salted egg white mass, and enzymolyze the mixture at 55°C for 3 hours; Put the enzymatic solution in boiling water for 10 minutes to inactivate the enzyme, and then cool it down immediately;

[0039] (5) Centrifugation: Centrifuge the obtained enzymolysis solution at 4500r / min for 25min, take the supernatant to obtain the preliminary enzymolysis supernatant;

[0040] (6) Secondary enzymatic hydrolysis: Add flavor protease to the prelimin...

Embodiment 2

[0047] (1) Collection of raw materials: recover salted duck egg white to obtain salted duck egg white recovery liquid;

[0048] (2) Dilution: Dilute the recovered salted duck egg white liquid obtained in step (1) by 4 times with distilled water to obtain a salted egg white dilution;

[0049] (3) Denaturation: Denature the salted egg white dilution obtained in step (2) at 100°C for 10 minutes, and cool;

[0050] (4) Enzymolysis and enzyme inactivation: adjust the initial pH of the salted egg white dilution to 6.0, add 2.5% of the mass of salted egg white papain, and enzymolyze the mixture at 60°C for 4 hours; Put the enzymatic solution in boiling water for 10 minutes to achieve the effect of inactivating the enzyme;

[0051] (5) Centrifugation: Then immediately cool down, centrifuge the obtained enzymolysis solution at 4500r / min for 20min, take the supernatant to obtain the preliminary enzymolysis supernatant;

[0052] (6) Second enzymolysis: Add flavor protease to the prelim...

Embodiment 3

[0059] (1) Collection of raw materials: recover salted duck egg white to obtain salted duck egg white recovery liquid;

[0060] (2) Dilution: Dilute the recovered salted duck egg white liquid obtained in step (1) 6 times with distilled water to obtain a salted egg white dilution;

[0061] (3) Denaturation: Denature the salted egg white dilution obtained in step (2) at 100°C for 10 minutes, and cool;

[0062] (4) Enzymolysis and enzyme inactivation: adjust the initial pH of the salted egg white dilution to 6.5, add papain at 4% of the salted egg white mass, and enzymolyze the mixture at 65°C for 4 hours;

[0063] (5) Centrifugation: After the enzymolysis is completed, immediately put the enzymolysis solution in boiling water for 10 minutes to achieve the effect of inactivating the enzyme, then cool it immediately, and centrifuge the obtained enzymolysis solution at 4500r / min for 25 minutes to obtain the supernatant for preliminary enzymolysis Serum;

[0064] (6) Secondary enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com