Fractionating tower, fractionating system and method for producing heat conducting oil

A fractionation tower and tower body technology, which is applied in fractionation, hydrocarbon distillation, petroleum industry, etc., can solve the problems of small output of heat transfer oil products, poor fractionation effect of raw material oil, and low performance index, so as to improve output and performance index, promote Mass transfer and heat transfer, the effect of improving the effect of fractionation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Distillation tower

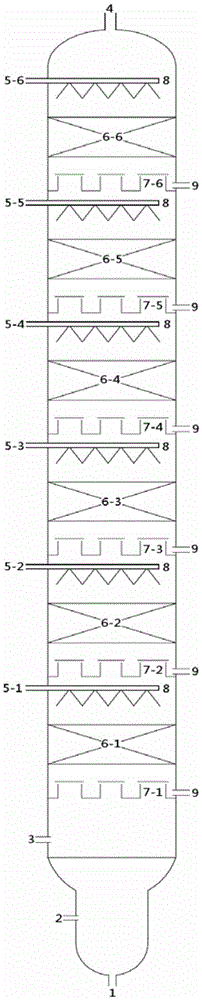

[0083] This embodiment provides a kind of Figure 5 Structural fractionating tower, Figure 5 It is a structural schematic diagram of the fractionation tower provided by Example 1 of the present invention. Figure 5 Among them, 1 is the bottom liquid outlet, 2 is the stripping steam inlet, 3 is the feed inlet, 4 is the tower top steam outlet, 6 is the packing layer, 7 is the oil collection tank, and 9 is the oil discharge port.

[0084] The fractionation tower provided by this embodiment includes a tower body, the inner diameter of the tower is 2800mm, and the height of the tower body is 35000mm. The bottom end of the tower body is provided with a tower bottom liquid outlet 1, and the side wall of the tower body is provided with a stripper at a distance of 1000mm from the bottom of the tower. The steam inlet 2 is provided with a feed inlet 3 at a distance of 4000 mm from the tower bottom on the side wall of the tower body, and a tower top steam ou...

Embodiment 2

[0089] Distillation tower

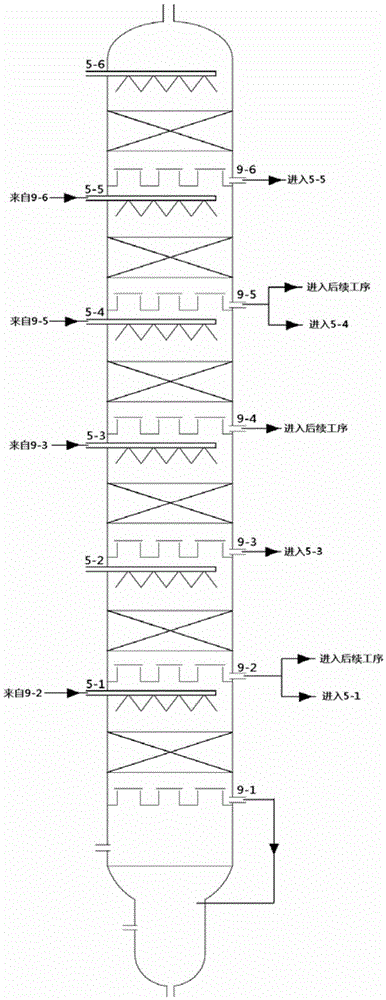

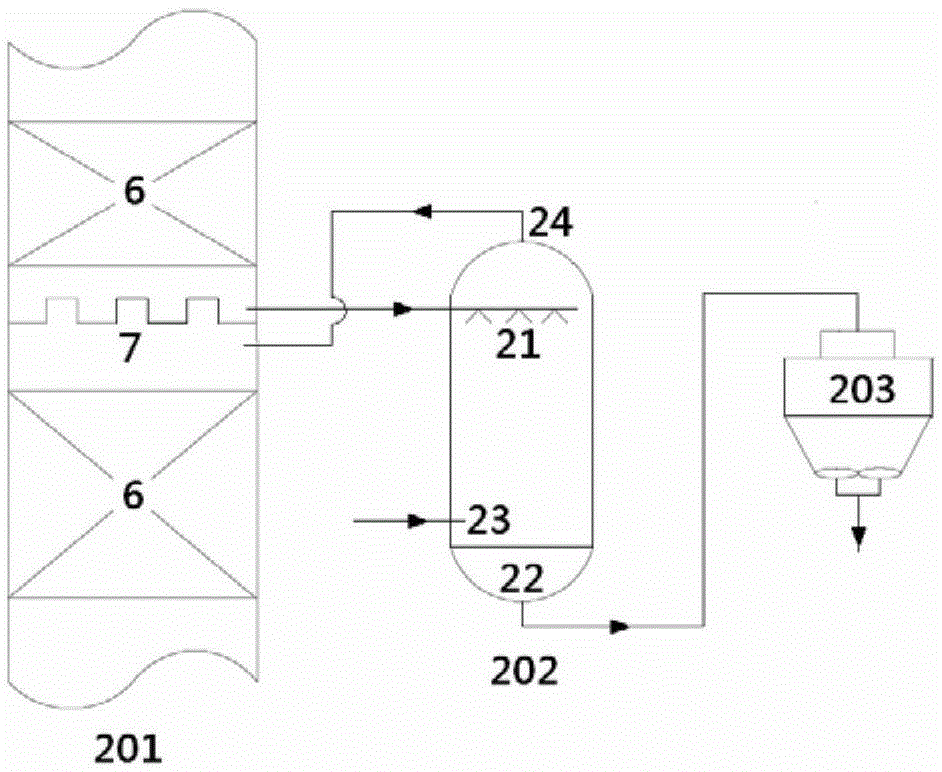

[0090] This embodiment provides a kind of Figure 6 Structural fractionating tower, Figure 6 It is a structural schematic diagram of the fractionation tower provided by Example 2 of the present invention. Figure 6 Among them, 1 is the bottom liquid outlet, 2 is the stripping steam inlet, 3 is the feed inlet, 4 is the tower top steam outlet, 5-1 is the inlet level of the first fractionation liquid, and 5-3 is the third fractionation Liquid inlet level, 5-4 is the fourth fractionation liquid inlet level, 5-5 is the fifth fractionation liquid inlet level, 6-1 is the first packing layer, 6-2 is the second packing layer, 6-3 6-4 is the fourth packing layer, 6-5 is the fifth packing layer, 6-6 is the sixth packing layer, 7-1 is the first oil collection tank, 7-2 is the second oil collection tank , 7-3 is the third oil collection tank, 7-4 is the fourth oil collection tank, 7-5 is the fifth oil collection tank, 7-6 is the sixth oil collection tank, 8 ...

Embodiment 3

[0100] Distillation tower

[0101] This embodiment provides a kind of Figure 7 Structural fractionating tower, Figure 7 It is a structural schematic diagram of the fractionation tower provided by Embodiment 3 of the present invention. Figure 7 Among them, 1 is the bottom liquid outlet, 2 is the stripping steam inlet, 3 is the feed inlet, 4 is the tower top steam outlet, 5-1 is the inlet level of the first fractionation liquid, and 5-2 is the second fractionation Liquid inlet level, 5-3 is the third fractionation liquid inlet level, 5-4 is the fourth fractionation liquid inlet level, 5-5 is the fifth fractionation liquid inlet level, 5-6 is the sixth fractionation liquid inlet level Liquid level, 6-1 is the first packing layer, 6-2 is the second packing layer, 6-3 is the third packing layer, 6-4 is the fourth packing layer, 6-5 is the fifth packing layer, 6- 6 is the sixth packing layer, 7-1 is the first oil collection tank, 7-2 is the second oil collection tank, 7-3 is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com