Extraction tower used for ethyl vanillin

A technology of ethyl vanillin and extraction tower, which is applied in liquid solution solvent extraction, separation/purification of carbonyl compounds, essential oils/fragrances, etc. It can solve problems such as difficulty in starting the motor and achieve an easy start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

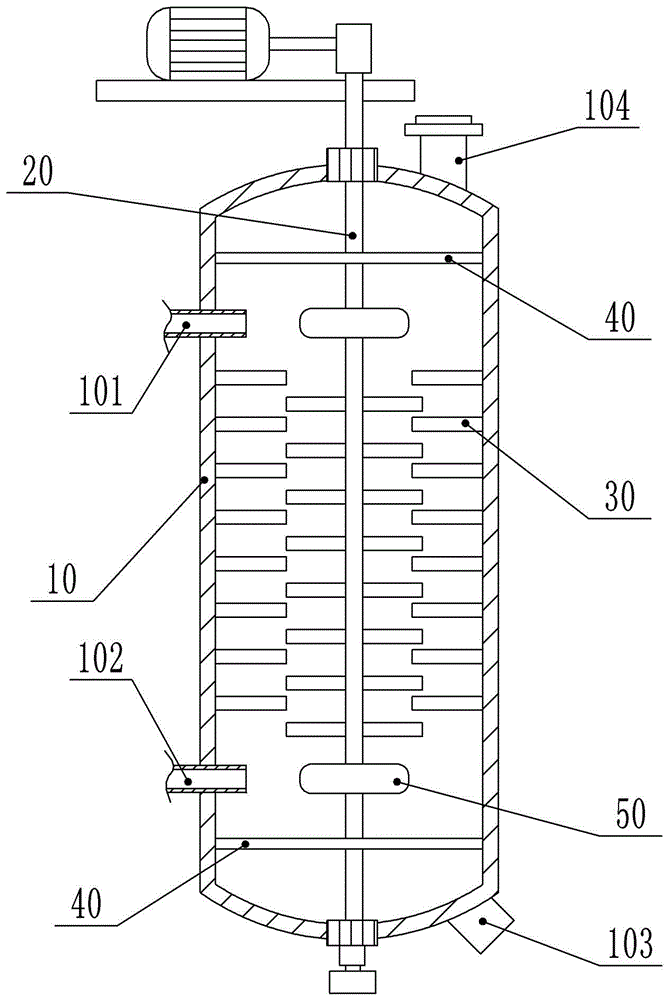

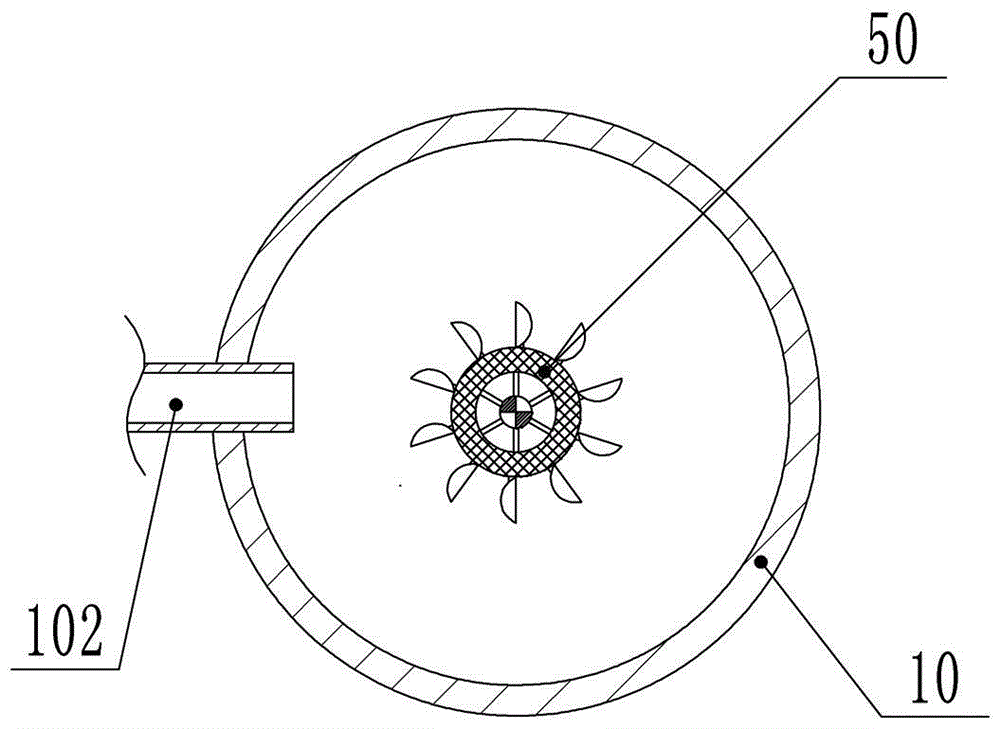

[0014] The reference signs in the drawings of the description include: tower body 10, heavy liquid inlet 101, light liquid inlet 102, raffinate phase outlet 103, extract phase outlet 104, stirring shaft 20, sieve plate 30, filter plate 40, water wheel 50 .

[0015] Such as figure 1 , figure 2 As shown, the extraction tower for ethyl vanillin includes a tower body 10, and a heavy liquid inlet 101 and a light liquid inlet 102 are arranged on the left side wall of the tower body 10. The raffinate phase outlet 103 is arranged at the bottom of the tower body 10 , and the extract phase outlet 104 is arranged at the top of the tower body 10 . A stirring shaft 20 is arranged in the center of the tower body 10, and the stirring shaft 20 is connected to the output end of the motor. Eight layers of turntables are welded on the stirring shaft 20 , and sieve plates 30 interlaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com