A preparation method of anti-aging and spherical cerium oxide with large specific surface area

A large specific surface area, cerium oxide technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problem of catalytic performance degradation and achieve the effect of prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

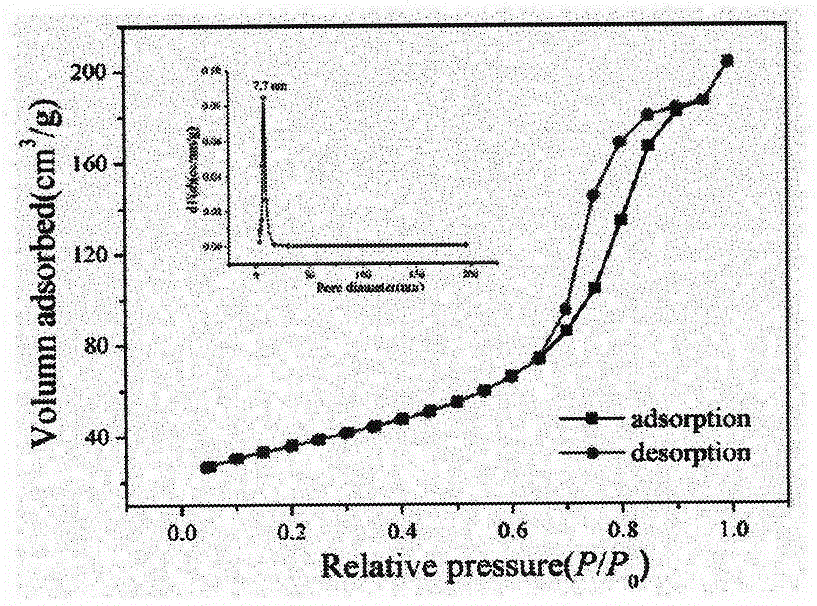

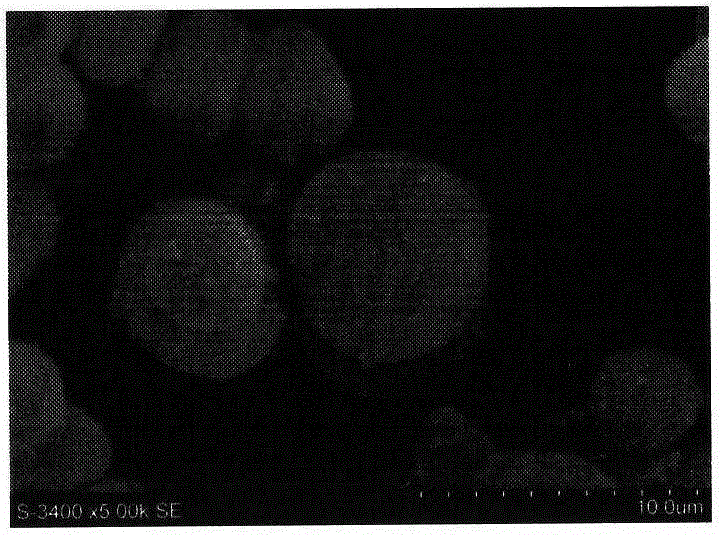

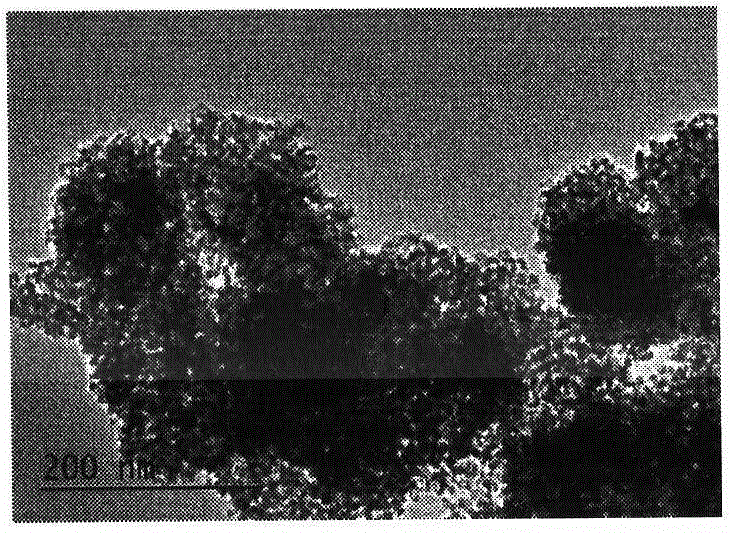

Embodiment 1

[0021] Measure 35.8ml triethylenetetramine, ethanol and deionized water respectively and mix evenly, add 35g hexadecyltrimethylammonium bromide to it, stir to make it dissolve, obtain surfactant solution; 1000ml concentration 0.12mol / L (NH 4 ) 4 Ce(NO 3 ) 6 solution and heated to 90°C, added the prepared surfactant solution to it, adjusted the pH of the reaction system to 10 with ammonia water, and aged for 72 hours to obtain a gray precipitate that was easy to filter, and the precipitate was washed with ethanol and deionized Washed twice with water, filtered, and dried at 80°C to obtain a loose yellow powder with a firing temperature of 400°C and a specific surface area of 140.1m after holding for 3 hours 2 / g, or the specific surface area after burning at 800°C for 3 hours is 92.23m 2 / g, median particle size D 50 Spherical cerium oxide with aging resistance and large specific surface area of 9.85μm.

Embodiment 2

[0023] Measure 50.7ml triethylenetetramine, ethanol and deionized water respectively and mix evenly, add 50g hexadecyltrimethylammonium bromide to it, stir to make it dissolve, obtain surfactant solution; 1000ml of Ce(NO 3 ) 4 solution and heated to 90°C, added the prepared surfactant solution to it, adjusted the pH of the reaction system to 11 with ammonia water, and aged for 72 hours to obtain a gray precipitate that was easy to filter, and the precipitate was washed with ethanol and deionized Washed twice with water, filtered, and dried at 80°C to obtain a loose yellow powder with a firing temperature of 400°C and a specific surface area of 176.4m after holding for 3 hours 2 / g, or after burning at 800°C for 3 hours, the specific surface area is 111.8m 2 / g, median particle size D 50 Spherical cerium oxide with a size of 9.08μm, very good fluidity, aging resistance and large specific surface area.

Embodiment 3

[0025] Measure 68.6ml triethylenetetramine, ethanol and deionized water respectively and mix uniformly, add 50.3g hexadecyltrimethylammonium bromide wherein, stir and make it dissolve, obtain surfactant solution; Add 1000ml concentration of 0.23mol / L (NH 4 ) 4 Ce(NO 3 ) 6 solution and heated to 90°C, added the prepared surfactant solution to it, adjusted the pH of the reaction system to 9 with ammonia water, and aged for 24 hours to obtain a gray precipitate that was easy to filter, and the precipitate was washed with ethanol and deionized Washed twice with water, filtered, and dried at 80°C to obtain a loose yellow powder with a firing temperature of 400°C and a specific surface area of 142.5m after holding for 3 hours 2 / g, or the specific surface area after burning at 800°C for 3 hours is 77.3m 2 / g, median particle size D 50 Spherical cerium oxide with a size of 11.2μm, very good fluidity, aging resistance and large specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com