Combined plant for high-concentration organic wastewater treatment

A technology of organic wastewater treatment and combined device, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. The effect of less manual intervention and fine crushing of sludge particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

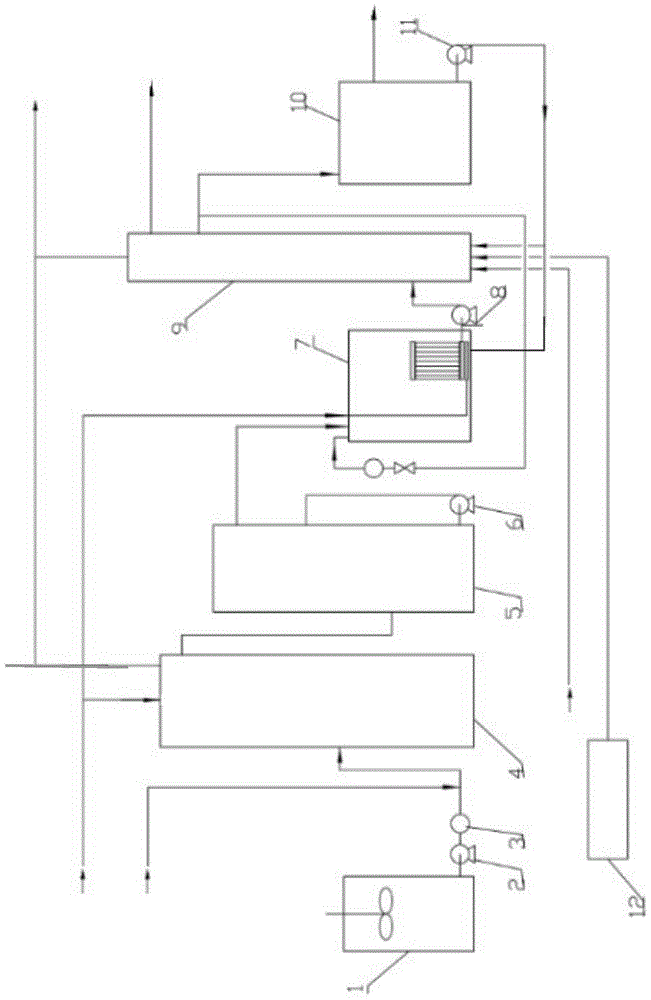

[0031] Such as Figure 1-11As shown, the high-concentration organic wastewater once-standard treatment combined device includes regulating tank 1, wastewater lifting pump 2, flow meter 3, ABGR reactor 4, acidification hydrolysis anaerobic reactor 5, circulating reflux pump 6, and MBR bioreactor 7 , Self-priming pump 8, ozone catalytic oxidation tower 9, clear water tank 10, backwash pump 11, ozone generator 12.

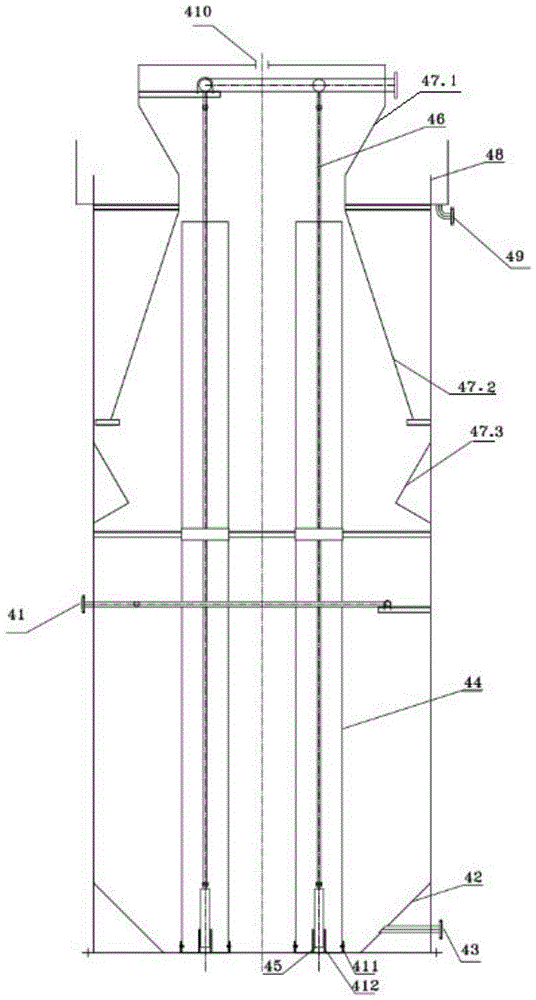

[0032] ABGR reactor 4 includes ABGR body, ABGR water inlet 41, conical bottom steel structure I42, ABGR mud outlet 43, ascending cylinder 44, aeration head 45, aeration branch pipe 46, conical assembly I47, overflow weir groove I48 , ABGR water outlet 49, tail gas discharge port 410, rising cylinder fixing sleeve 411 and aeration head fixing sleeve 412. The cone angle of the cone-bottom steel structure I42 is 45-55°, and the cone-bottom steel structure I42 is connected with the ABGR mud outlet 43. 4-6 ascending tube fixing sleeves 411 are welded in a circular distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com