Liquid cement grinding aid and its preparation method and application method

A grinding aid enhancer and cement technology, applied in the field of cement additives, can solve the problem of small contribution to the strength of cement in the later stage, and achieve the effects of reducing electrostatic adsorption, improving workability, and reasonable particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

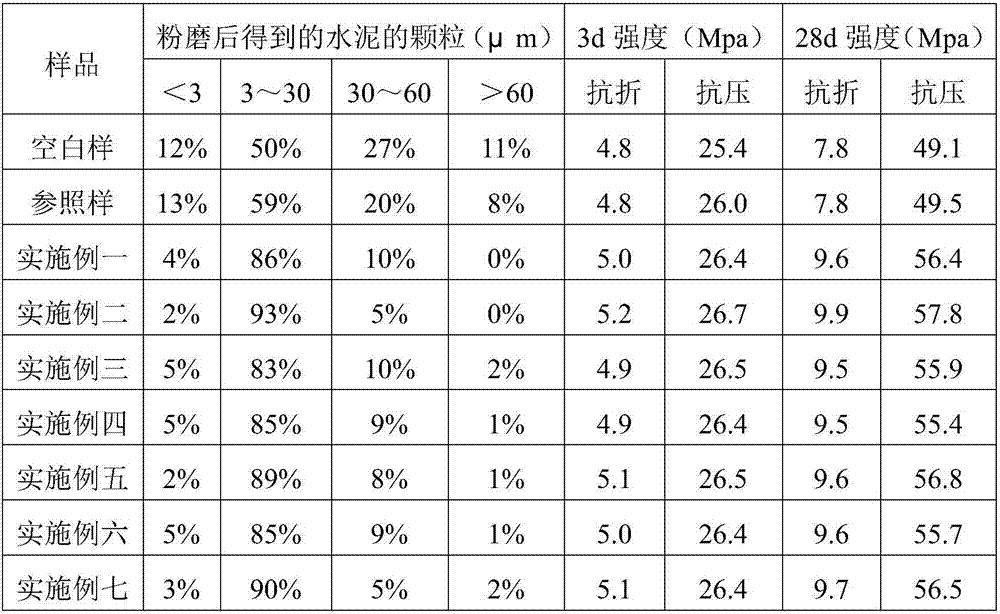

Examples

Embodiment 1

[0033] Take 2 parts of molasses (based on converted sugar, the total sugar content is 40wt%), 2 parts of PEO-b-PPO (the degree of polymerization of PEO is 10-15, and the degree of polymerization of PPO is 150-160), 3 parts of humic sodium naphthalene sulfonate (particle size: 80-120 mesh), 2 parts of naphthalenesulfonate formaldehyde polymer and 15 parts of water, stir and mix evenly to obtain S1 mixed solution; add 50 parts of triethanolamine and 5 parts of glycerin to the S1 mixed solution and 35 parts of water, stirred and mixed uniformly to obtain the liquid cement grinding aid enhancer of the present invention. Before the liquid cement grinding aid enhancer is added to the cement grinding process of cement products, the mass ratio of the liquid cement grinding aid enhancer to the cement product is 0.01% to 0.03%.

Embodiment 2

[0035]Take 5 parts of molasses (based on converted sugar, the total sugar content is 50wt%), 5 parts of PEO-b-PPO (the degree of polymerization of PEO is 35-40, and the degree of polymerization of PPO is 180-200), 5 parts of humic sodium naphthalene sulfonate (particle size: 80-120 mesh), 5 parts of naphthalenesulfonate formaldehyde polymer and 30 parts of water, stir and mix evenly to obtain S1 mixed solution; add 60 parts of triethanolamine, 10 parts of glycerin and 50 parts of water, stirred and mixed evenly to obtain the liquid cement grinding aid enhancer of the present invention. Before the liquid cement grinding aid enhancer is added to the cement grinding process of cement products, the mass ratio of the liquid cement grinding aid enhancer to the cement product is 0.01% to 0.03%.

Embodiment 3

[0037] Take 0.1 part of molasses (based on the amount of converted sugar, the total sugar content is 30wt%), 0.1 part of PEO-b-PPO (the degree of polymerization of PEO is 4, and the degree of polymerization of PPO is 80-90), 0.1 part of sodium humate (particle size is 80-120 mesh), 1 part of naphthalenesulfonate formaldehyde polymer and 10 parts of water, stir and mix evenly to obtain S1 mixed solution; add 40 parts of triethanolamine, 1 part of glycerin and 20 parts of S1 mixed solution part of water, stirred and mixed evenly to obtain the liquid cement grinding aid enhancer of the present invention. Before the liquid cement grinding aid enhancer is added to the cement grinding process of cement products, the mass ratio of the liquid cement grinding aid enhancer to the cement product is 0.01% to 0.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com