Easily-coating type flexible waterproof slurry and preparation method thereof

A flexible waterproof and coating technology, applied in the field of waterproof coatings, can solve the problems of inability to guarantee product performance and waterproof effect, and achieve the effect of guaranteed performance and waterproof effect, excellent construction performance, and guaranteed waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

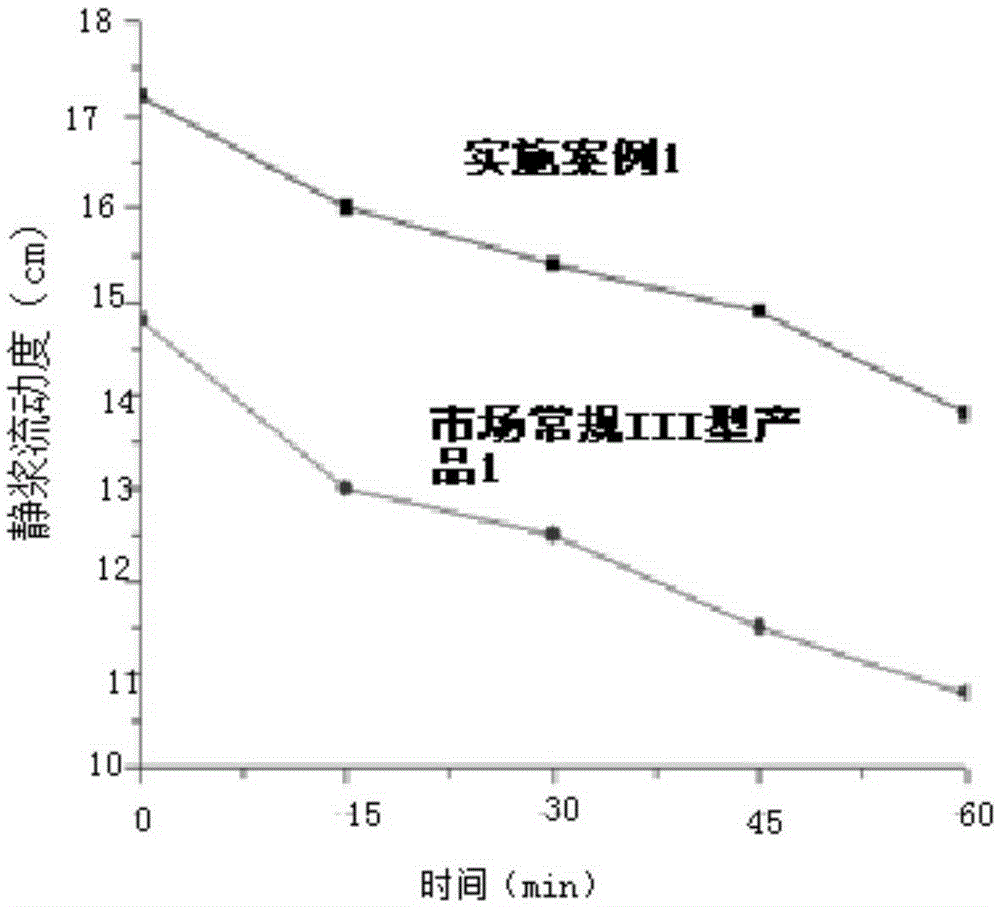

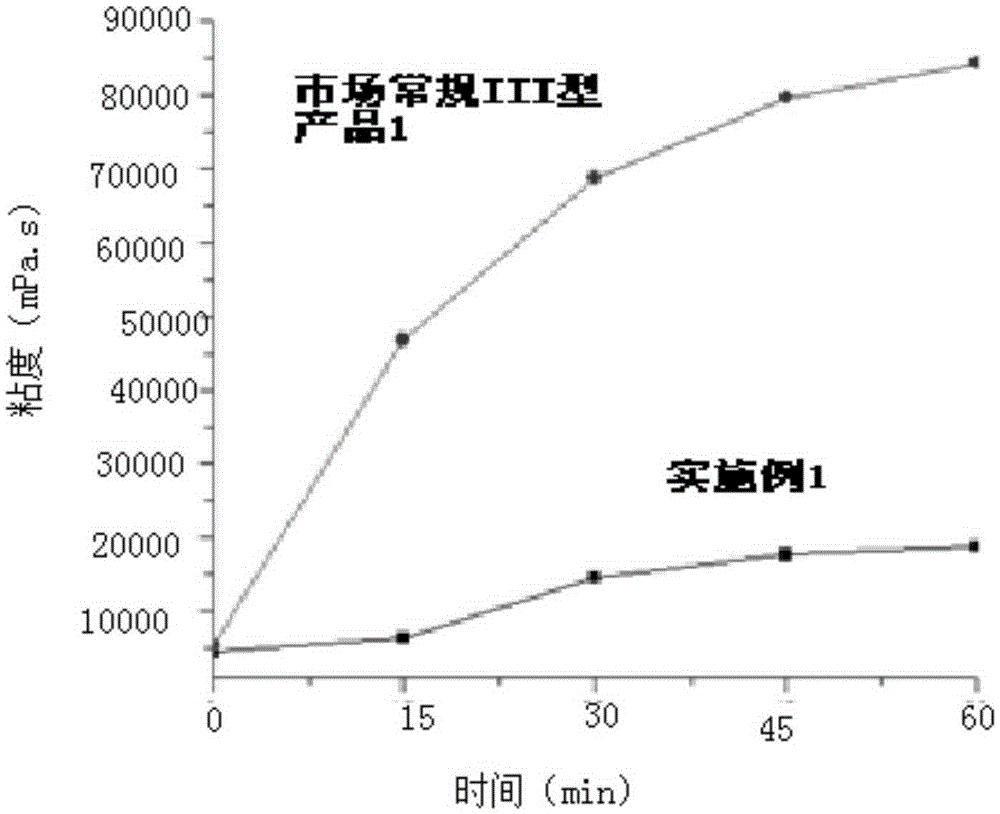

Embodiment 1

[0028] Prefabrication of component A: mix 90 weight of Bardford 3001F emulsion, 2 weight of defoamer, 0.3 weight of dispersant, 0.1 weight of bactericide, and 1.5 weight of antifungal agent in a dispersing mixer at low speed for 20 minutes, and pack it into a component A .

[0029] Prefabricated component B: premix 40 weights of conch 42.5 gray cement, 40 weights of 80-120 mesh quartz sand, 10 weights of 325 mesh quartz powder, 0.02 weight polyvinyl alcohol, and 1 weight water reducer in a horizontal mixer for 15 minutes at high speed , bagged as component B.

[0030] The two-component easy-to-coat flexible waterproof slurry composed of component A and component B shall be mixed evenly on site according to the weight ratio of A:B:water of 1:2.5:0.2 during construction.

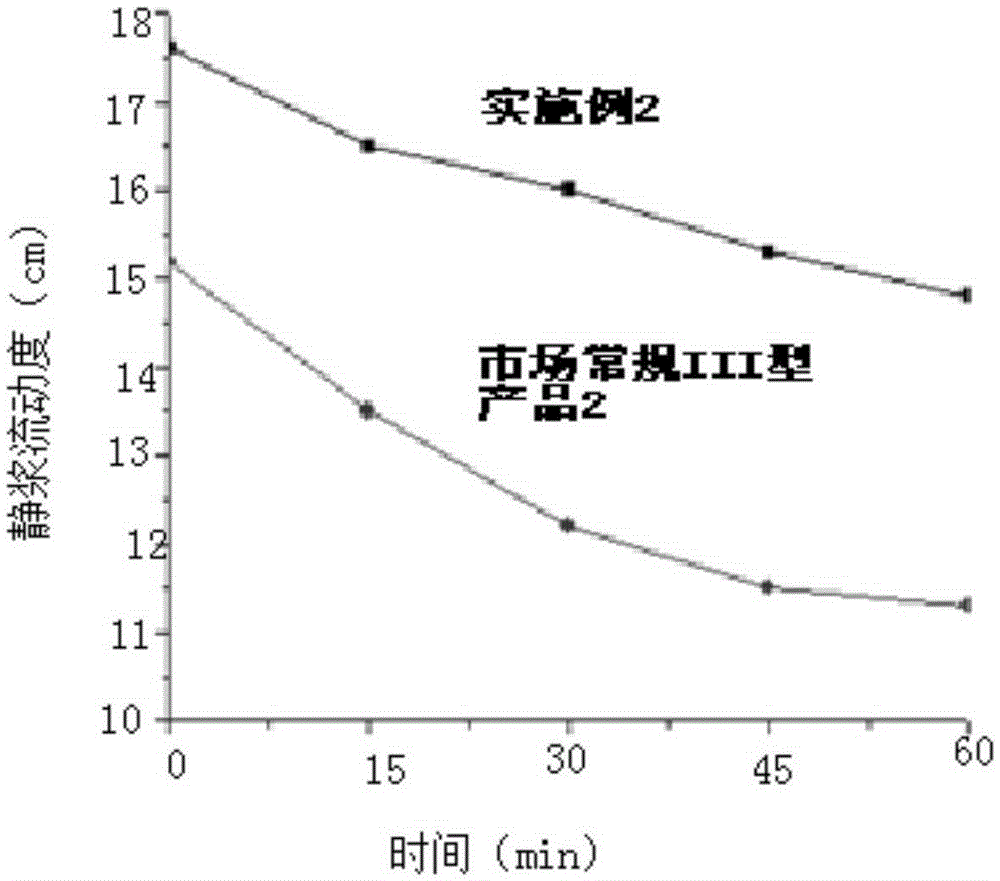

Embodiment 2

[0032] Prefabricated component A: Mix 60 weights of BASF S400 emulsion, 30 weights of BASF S400 emulsion, 2 weights of defoamer, 0.3 weight of dispersant, 0.1 weight of bactericide, and 1.5 weight of antifungal agent in a dispersing mixer at low speed for 20 minutes. Bag is A component.

[0033] Prefabricated component B: premix 40 weights of conch 42.5 gray cement, 40 weights of 80-120 mesh quartz sand, 10 weights of 325 mesh quartz powder, 0.02 weight polyvinyl alcohol, and 1 weight water reducer in a horizontal mixer for 15 minutes at high speed , bagged as component B.

[0034] The two-component easy-to-coat flexible waterproof slurry composed of component A and component B shall be mixed evenly on site according to the weight ratio of A:B:water of 1:2.5:0.2 during construction.

Embodiment 3

[0036] Prefabricated component A: Mix 70 weights of BASF S400 emulsion, 20 weights of BASF S400 emulsion, 2 weights of defoamer, 0.5 weight of dispersant, 0.1 weight of bactericide, and 1.5 weight of antifungal agent in a dispersing mixer at low speed for 20 minutes. Bag is A component.

[0037] Prefabricated component B: premix 40 weights of conch 42.5 gray cement, 45 weights of 80-120 mesh quartz sand, 10 weights of 325 mesh quartz powder, 0.05 weight polyvinyl alcohol, and 1 weight water reducer in a horizontal mixer for 15 minutes at high speed , bagged as component B.

[0038] The two-component easy-to-coat flexible waterproof slurry composed of component A and component B shall be mixed evenly on site according to the weight ratio of A:B:water of 1:2.5:0.2 during construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com