Method for preparing cyclooctanol and cyclooctanone through cyclooctane oxidation

A technology of cyclooctanol and cyclooctane, which is applied in the field of fine chemical manufacturing, can solve the problems of expensive oxidants and serious pollution, and achieve the effects of low cost, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

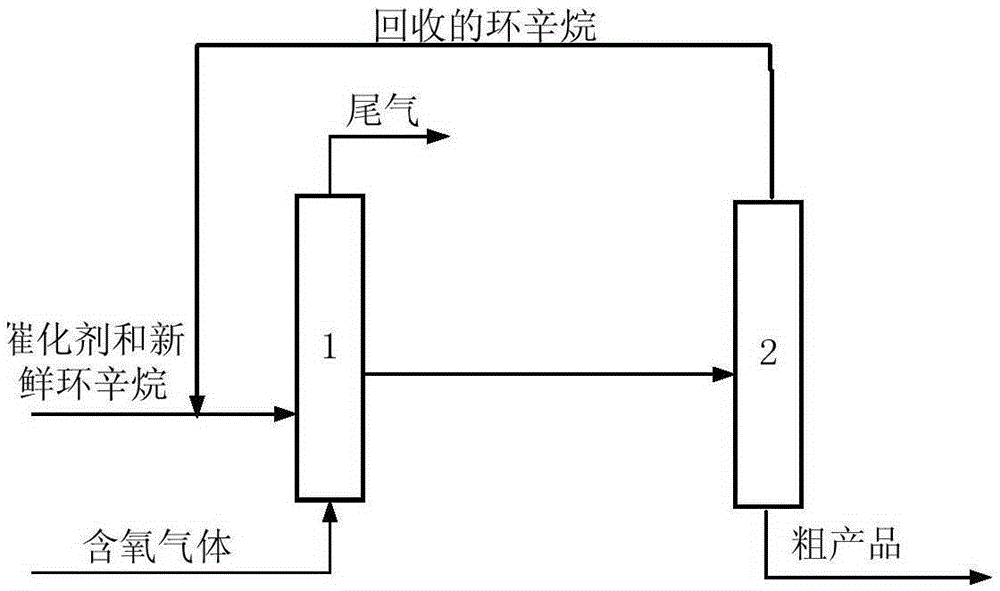

Method used

Image

Examples

Embodiment 1

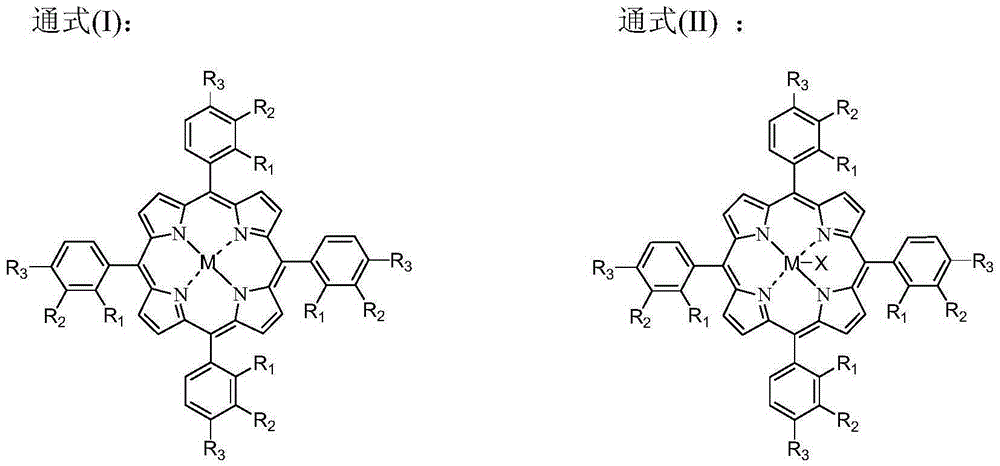

[0048] The catalyst dissolved in the fresh cyclooctane added to the system is Co(Ac) 2 .4H 2 O, metal phthalocyanine (R) with general formula (IV) structure 1 =CH 3 CH 2 , R 2 =H, M=Mn), the metalloporphyrin (R 1 =R 2 = H, R 3 =CH 3 , M=Cu) mixture with a total concentration of 225 ppm. When the device is in steady state operation, the flow rate of fresh cyclooctane added to the oxidation reactor is 22.5mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase substances is 0.4h, and the pressurized air is continuously fed into the In the oxidation reactor, the reaction temperature of the system is maintained at 237° C., and the reaction pressure is 1.8 MPa. After sampling analysis, the conversion rate of cyclooctane in the system is 98.1%, and the total selectivity of cyclooctanol and cyclooctanone is 91.6%, wherein the selectivity of cyclooctanol is 71.9%, and the selectivity of cyclooctanone is 19.7%. %.

Embodiment 2

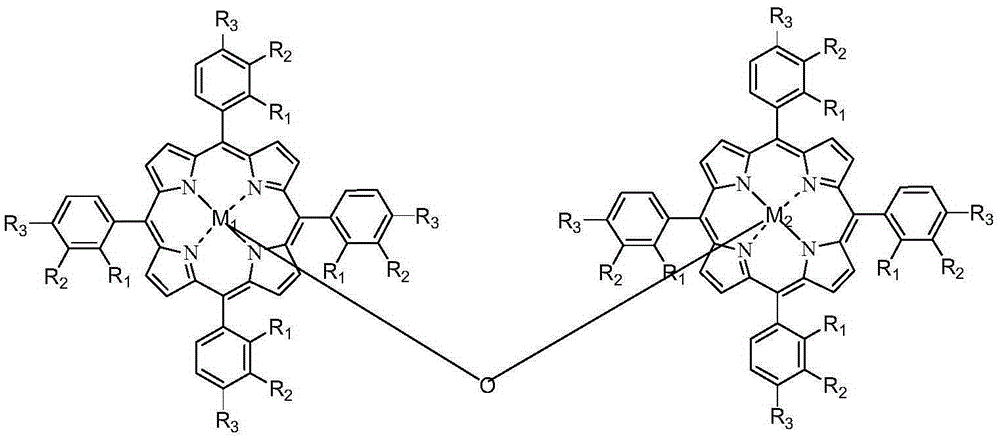

[0050] The catalyst that dissolves in the fresh cyclooctane that adds system is N-hydroxyl phthalimide, the metal phthalocyanine (R with general formula (IV) structure 1 =OH, R 2 =H, M=Ru) and metalloporphyrins (R 1 =R 3 = H, R 2 =OH,M 1 = M 2 =Mn), the total concentration is 10000ppm. When the device is in steady state operation, the flow rate of fresh cyclooctane added to the oxidation reactor is 2.1mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase substances is 6.0h, and the pressurized pure oxygen is continuously passed through into the oxidation reactor, maintaining the reaction temperature of the system at 120°C and the reaction pressure at 0.1MPa. After sampling analysis, the conversion rate of cyclooctane in the system is 98.4%, and the total selectivity of cyclooctanol and cyclooctanone is 90.7%, wherein the selectivity of cyclooctanol is 64.7%, and the selectivity of cyclooctanone is 26.0%. %.

Embodiment 3

[0052] The catalyst dissolved in the fresh cyclooctane added to the system is Cr(NO 3 ) 4 , N-acetyl phthalimide, metal phthalocyanine (R 1 =OCH 3 , R 2 =H, M=Ni) and the metalloporphyrin (R 1 =R 3 =OCH 3 , R 2 =H, M=Fe) with a total concentration of 7800 ppm. During the steady state operation of the device, the flow rate of the fresh cyclooctane added in the oxidation reactor was 4.0mL / h. At this time, the average residence time of the oxidation reactor in terms of liquid phase material was 3.5h, and the oxygen concentration was 76%. The pressurized oxygen enrichment is continuously passed into the oxidation reactor, and the reaction temperature of the system is maintained at 151° C., and the reaction pressure is 0.3 MPa. After sampling analysis, the conversion rate of cyclooctane in the system is 98.6%, and the total selectivity of cyclooctanol and cyclooctanone is 90.3%, wherein the selectivity of cyclooctanol is 61.8%, and the selectivity of cyclooctanone is 28.6%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com