Preparation and application of novel dual-core organic skeleton material MIL-100(Fe-Mn)

An organic framework, fe-mn technology, applied in the field of preparation of new binuclear metal-organic framework material MIL-100, can solve the problem of few reports related to the synthesis of binuclear MOFs crystal, achieve excellent surface adsorption and chemical reactivity, and cheap source. , the effect of improving the production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation method of stable zero-valent nano-iron suspension.

[0035] Prepare 100mL, 2.5mol / LFe (NO 3 ) 3 ·9H 2 O solution will be 100mL, 5mol / LNaBH 4 The solution was dripped into the above Fe(NO) at a uniform speed of 5mL / min. 3 ) 3 ·9H 2 O solution. Vibrate while titrating. After all the titration is completed, continue to shake for 15 min until all the hydrogen is dissipated. The supernatant is removed by centrifugation at a centrifugation rate of 6000 r / min. The product was washed 3 times with deionized water, and finally the product was adjusted to 50 mL suspension solution with deionized water, and 0.3M (molar ratio 1:1) ethylenediaminetetraacetic acid (EDTA) and polyethylene glycol ( PEG) and ultrasonic dispersion to obtain a stable zero-valent nano-iron suspension with a concentration of about 28 mg / mL.

Embodiment 2

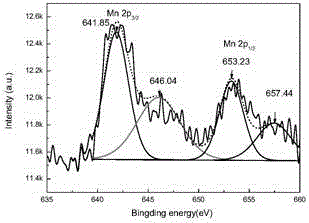

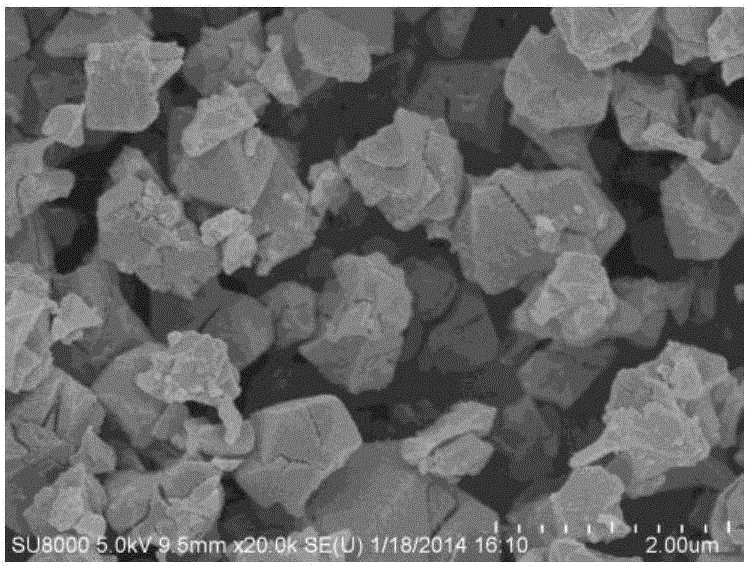

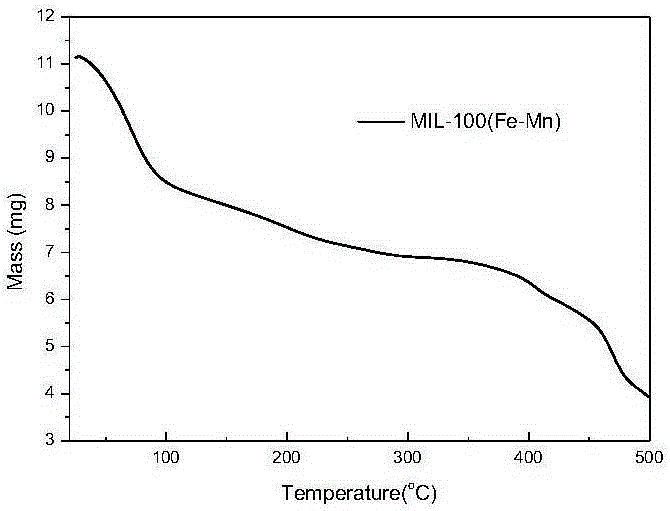

[0036] Example 2: Preparation method of MIL-100 (Fe-Mn) catalyst.

[0037] Add 5 ml of Mn (NO 3 ) 2 ·4H 2 O solution (1mol / L), H 3BTC (12.5 mmol) was ultrasonically dispersed at 80° C. for 2 h, and at the same time, HF (wt>40%) was slowly added dropwise, and the pH value of the solution was adjusted to 3-6. Then, the reactant was moved to a stainless steel reaction kettle with a polytetrafluoroethylene liner, sealed and placed in an oven to be heated, heated at 120°C for 8 hours and then heated to 150°C for 8 hours. After the reaction kettle was lowered to room temperature, the product was vacuum filtered, soaked in fresh absolute ethanol solution for about 24 hours, and then repeatedly washed with ethanol for several times. Finally, the product was heated in a vacuum drying oven at 80° C. overnight to obtain a pure orange powder, namely the organic framework material MIL-100 (Fe-Mn), with a yield of 89%.

Embodiment 3

[0039] According to the reactant Mn (NO 3 ) 2 ·4H 2 O solution (1mol / L) was increased to 10mL, H 3 The amount of BTC was increased to 25 mmol, and the amount of other raw materials and experimental procedures remained unchanged, and an orange-yellow MIL-100 (Fe-Mn) material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com