Preparation method for photoluminescent hydrogel composite material

A composite material and photoluminescence technology, which is applied in the field of preparing photoluminescent hydrogel composite materials by using waste foam plastics, can solve problems such as environmental pollution, waste of non-renewable resources, etc., and achieve the effect of increasing beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

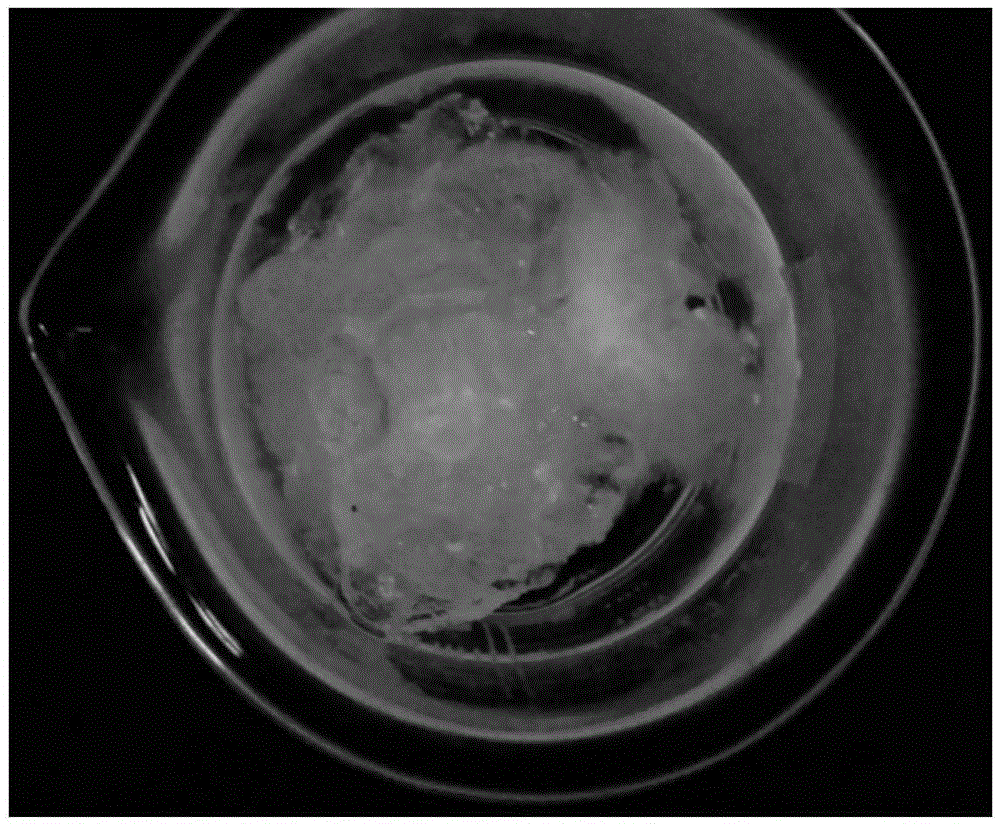

[0046] A preparation method for graft copolymerization into a super water-absorbing and water-retaining composite material with photoluminescence function, the specific steps are as follows:

[0047] (1) Dissolution of Styrofoam

[0048] Dissolve 0.54g of polystyrene foam plastics in a mixed organic solvent of ethyl acetate, toluene, and cyclohexane with a volume ratio of 3:3.8:1 to form a stable emulsion;

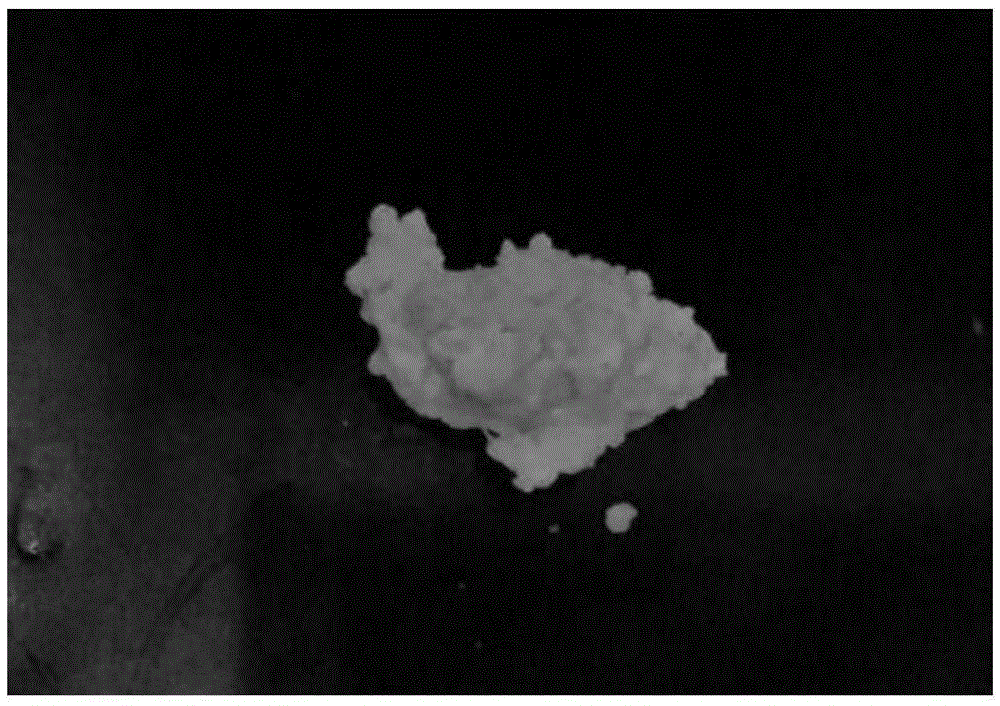

[0049] (2) Coating of long afterglow material particles

[0050] Under magnetic stirring conditions, add 0.018 g of Span-60 to the emulsion obtained in step (1) as a suspension stabilizer, then slowly add 3 g of long-lasting luminescent material therein, and stir at room temperature for 0.5-1 h;

[0051] (3) Preparation of sodium acrylate solution

[0052] Weigh 30g of acrylic acid monomer and place it in an ice-water bath, stir it magnetically, then weigh 10.1g of sodium hydroxide solid and 30g of deionized water to prepare a solution with a certain concentration, slowl...

Embodiment 2

[0057] A preparation method for graft copolymerization into a super water-absorbing and water-retaining composite material with photoluminescence function, the specific steps are as follows:

[0058] (1) Dissolution of Styrofoam

[0059] Dissolving 0.9 g of polystyrene foam plastics in a mixed organic solvent of ethyl acetate, toluene, and cyclohexane with a volume ratio of 3:3.8:1 forms a stable emulsion;

[0060] (2) Coating of phosphor particles

[0061] Under magnetic stirring conditions, add 0.03 g of Span-60 to the emulsion obtained in step (1) as a suspension stabilizer, then slowly add 5 g of long-lasting luminescent material therein, and stir at room temperature for 0.5-1 h;

[0062] (3) Preparation of sodium acrylate solution

[0063] Weigh 30g of acrylic acid monomer and place it in an ice-water bath, stir it magnetically, then weigh 10.1g of sodium hydroxide solid and 30g of deionized water to prepare a solution with a certain concentration, slowly add the sodium...

Embodiment 3

[0068] A preparation method for graft copolymerization into a super water-absorbing and water-retaining composite material with photoluminescence function, the specific steps are as follows:

[0069] (1) Dissolution of Styrofoam

[0070] Dissolving 1.44g of polystyrene foam plastics with a volume ratio of ethyl acetate, toluene, and cyclohexane in a mixed organic solvent of 3:3.8:1 forms a stable emulsion;

[0071] (2) Coating of phosphor particles

[0072] Under magnetic stirring conditions, add 0.048 g of Span-60 to the emulsion obtained in step (1) as a suspension stabilizer, then slowly add 8 g of long-lasting luminescent material therein, and stir at room temperature for 0.5-1 h;

[0073] (3) Preparation of sodium acrylate solution

[0074] Weigh 30g of acrylic acid monomer and place it in an ice-water bath, stir it magnetically, then weigh 10.1g of sodium hydroxide solid and 30g of deionized water to prepare a solution with a certain concentration, slowly add the sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com