A kind of transparent medical PVC material suitable for broad-wave light-shielding and preparation method thereof

The technology of PVC material and PVC resin is applied in the field of transparent medical PVC material and its preparation, which can solve the problems of narrow light-proof range and low light transmittance, and achieve the effects of reducing particle diameter, improving dispersibility and good light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Formula composition: 100 parts by weight of PVC resin, 50 parts by weight of plasticizer, 2.0 parts by weight of calcium / zinc stabilizer, 8.0 parts by weight of auxiliary heat stabilizer, 1.0 part by weight of lubricant, and 0.01 part by weight of light-shielding agent. Wherein said PVC resin is polyvinyl chloride resin by suspension method, and the degree of polymerization is 800-2500; said calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10-20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary thermal stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0016] The specific production steps are:

[0017] (1) Add iron oxide red, iron oxide yellow, and carbon black into the quantitative epoxy soybean oil ...

Embodiment 2

[0022] Embodiment 2 Formula composition: 100 parts by weight of PVC resin, 65 parts by weight of plasticizer, 1.5 parts by weight of calcium / zinc stabilizer, 10 parts by weight of auxiliary heat stabilizer, 0.7 parts by weight of lubricant, and 0.02 parts by weight of light-shielding agent, wherein The PVC resin is a suspension polyvinyl chloride resin with a degree of polymerization of 800-2500; the calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10 -20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary heat stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] Embodiment 3 Formula composition: 100 parts by weight of PVC resin, 75 parts by weight of plasticizer, 1.0 part by weight of calcium / zinc stabilizer, 12 parts by weight of auxiliary heat stabilizer, 0.5 part by weight of lubricant, and 0.05 part by weight of light-shielding agent, wherein The PVC resin is a suspension polyvinyl chloride resin with a degree of polymerization of 800-2500; the calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10 -20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary heat stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0026] The preparation method is the same as in Example 1.

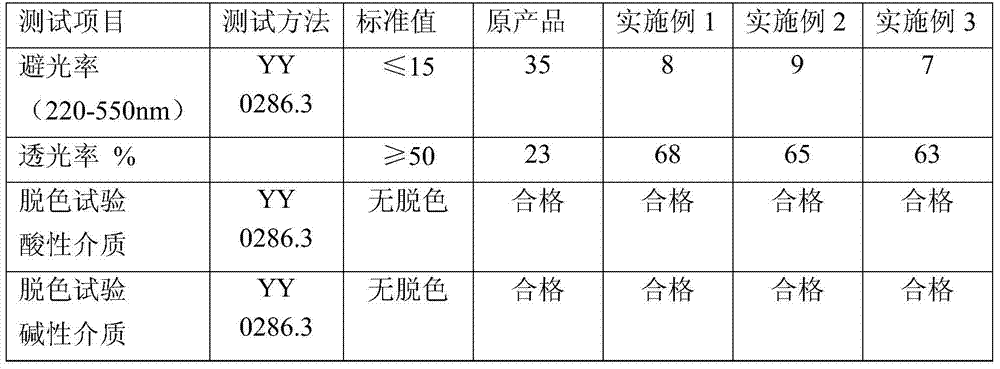

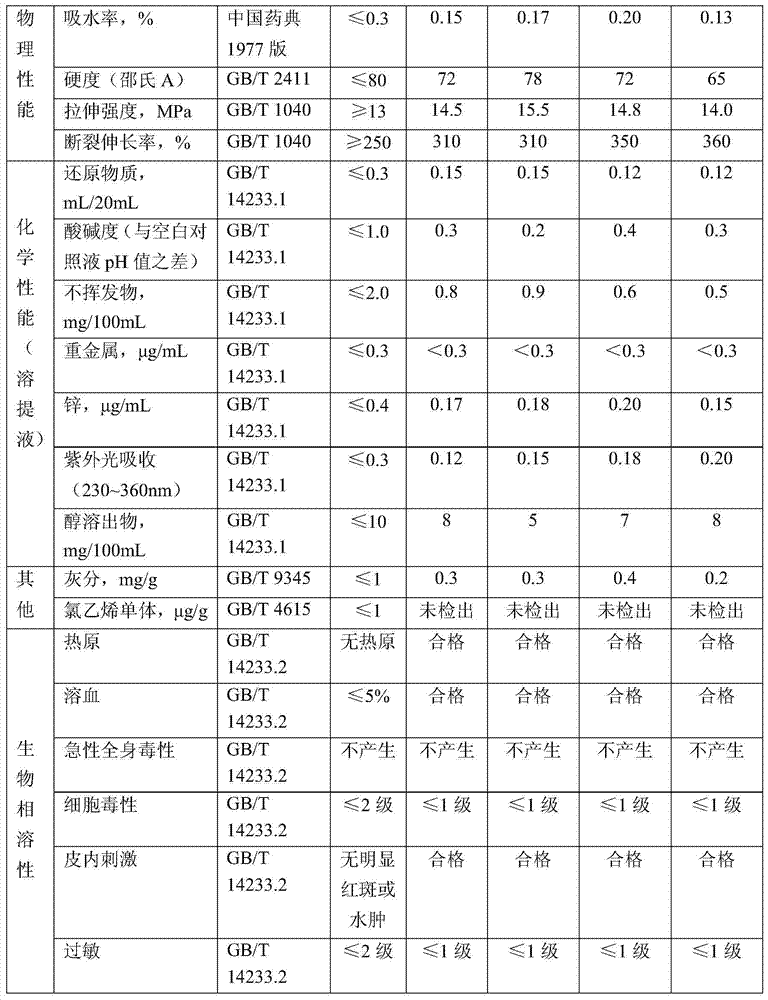

[0027] Select 3 examples with the basic formula of the present invention to carry out implementation ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com