Preparation method for self-repairing coating material and application thereof

A coating material and self-repairing technology, applied in the field of preparation of self-repairing coating materials, can solve the problems that damage cannot be repaired in time, product protection and decoration discount, etc., and achieve good market application prospects, economic benefits and Social benefits, effects of improving flame retardancy and decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments, and the described embodiments are only some of the embodiments of the present invention, not all of them.

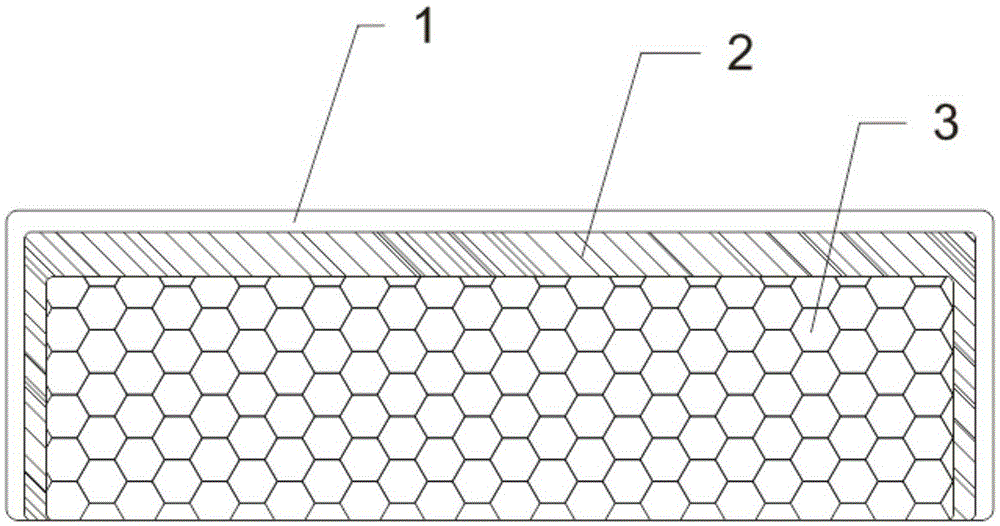

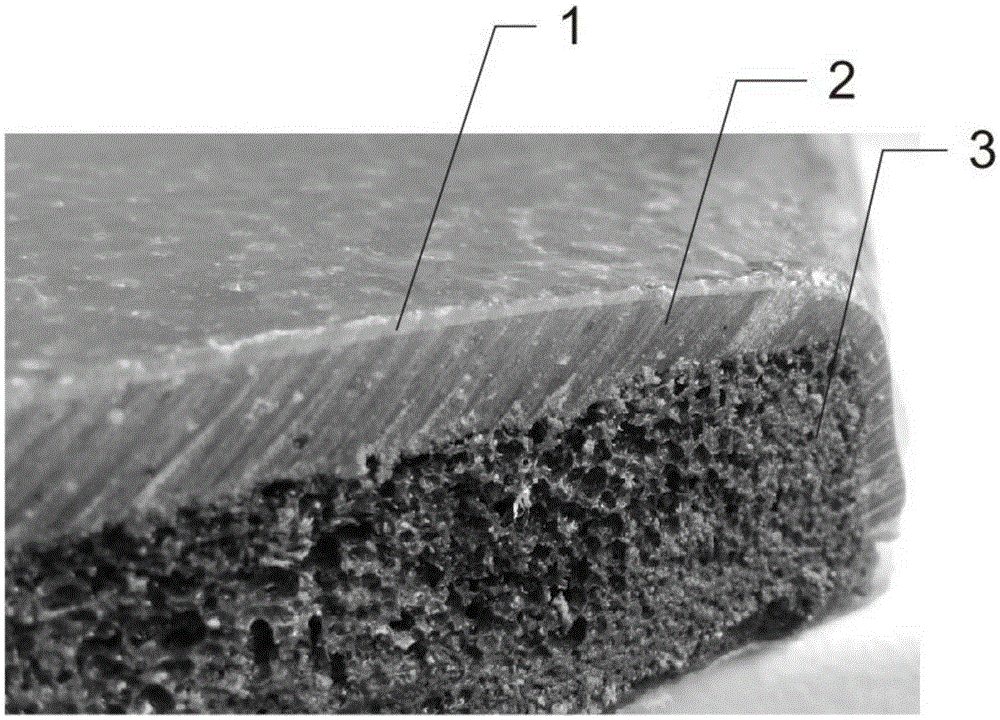

[0026] Such as Figure 1-3 As shown, the self-repairing coating material of the present invention comprises an inner layer repairing layer material and an outer layer material, the repairing layer material is added with urea-formaldehyde resin coated epoxy resin microcapsules, the surface layer material is added with a curing agent, and the repairing layer The preparation of the material and the surface material and its application include the following steps:

[0027] Step A, preparation of epoxy resin microcapsules (EP-UF microcapsules): first in a three-necked flask, dissolve 50 parts of urea in 90 to 100 parts of formaldehyde solution, adjust the pH of the solution to 8.0 to 10.0 with triethanola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com