Preparation method of waterborne polyurethane reflective insulation coating

A reflective heat-insulating coating, water-based polyurethane technology, applied in the field of coatings, can solve the problems of increasing the difficulty of color matching, easy failure, and no comprehensive consideration of reflection, heat insulation and radiation synergistic cooling, etc., to achieve broad market application prospects and reduce absorption , the effect of reducing air-conditioning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

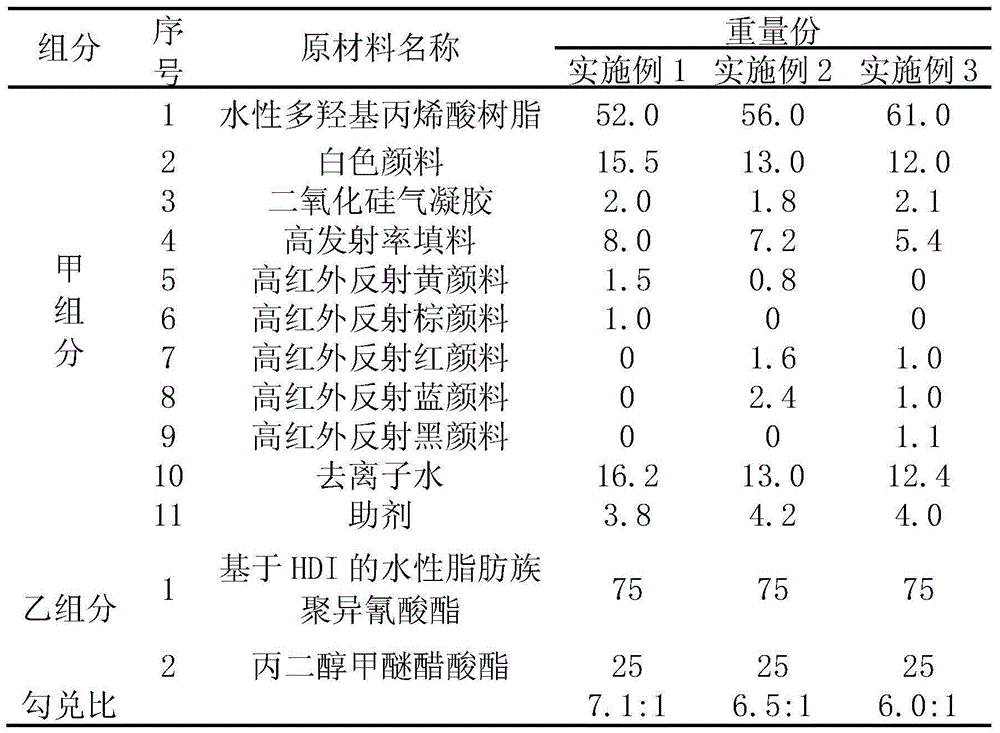

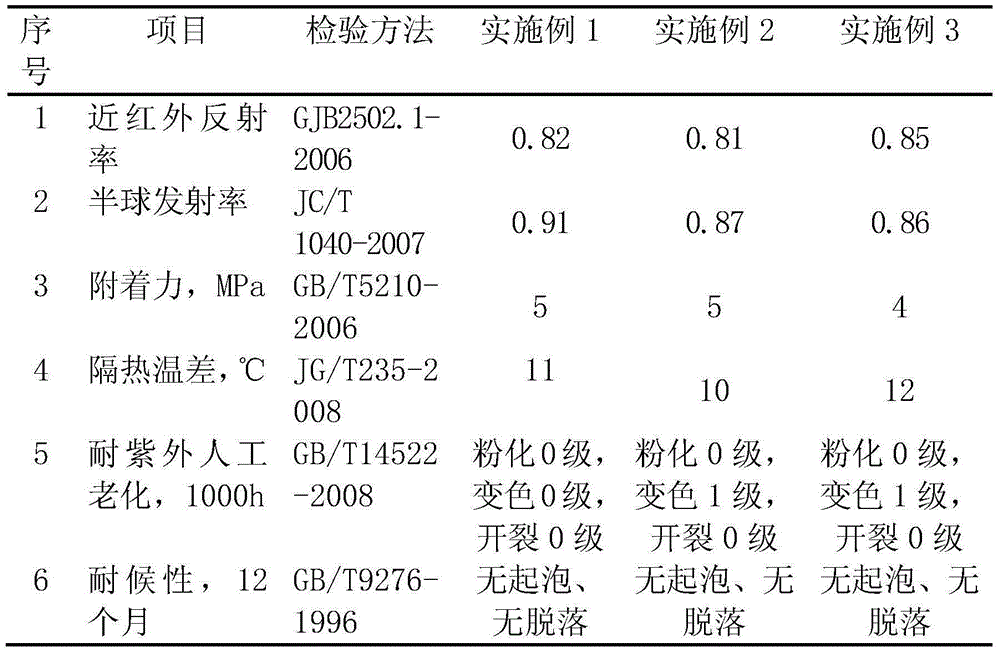

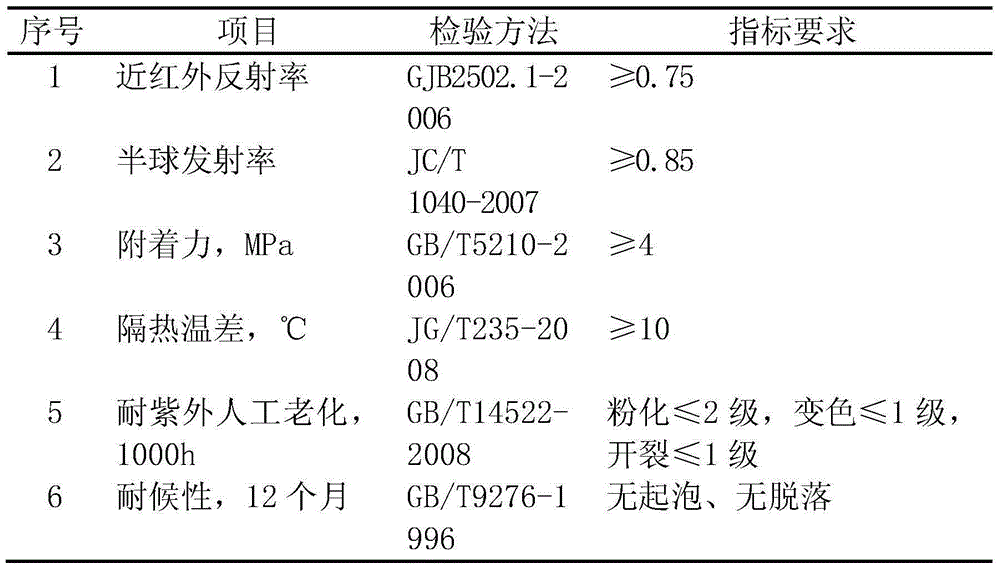

[0026] The invention relates to a preparation method of a water-based polyurethane reflective heat-insulating coating. The water-based polyurethane reflective heat-insulating coating is formed by blending component A and component B. The component A contains water-based polyhydroxy acrylic resin, high-near Infrared reflective white pigment, silica airgel, filler, high near-infrared reflective yellow pigment, high near-infrared reflective brown pigment, high near-infrared reflective red pigment, high near-infrared reflective blue pigment, high near-infrared reflective black pigment, Ionized water and additives. The high near-infrared reflective white pigment is any one of sodium zinc phosphate, titanium dioxide, or two of them. The filler is any one of silicon carbide, zirconia, limestone, and gypsum, or any two of them, or any three of them, or four of them. High near-infrared reflective yellow pigment is bismuth, zinc, phosphorus mixed oxide Bi 2 o 3 -ZnO-P 2 o 5 . High...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com