Workover fluid tackifier and preparation method of same

A technology of viscosifier and workover fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., which can solve the problems of low high temperature resistance and achieve the effect of improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

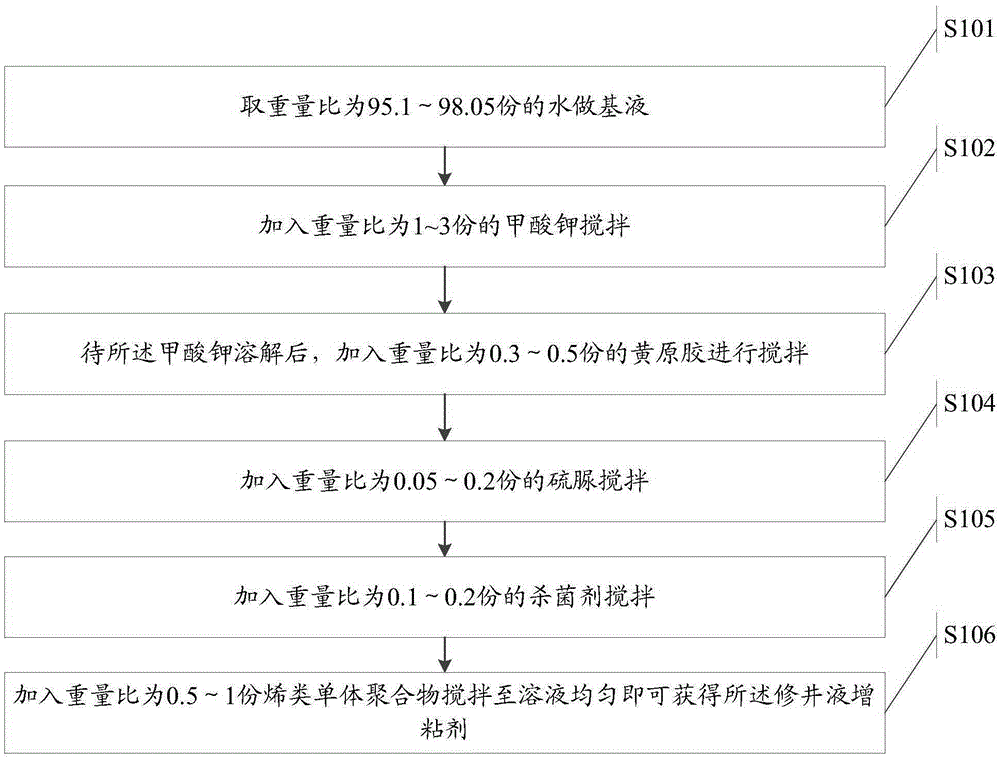

Method used

Image

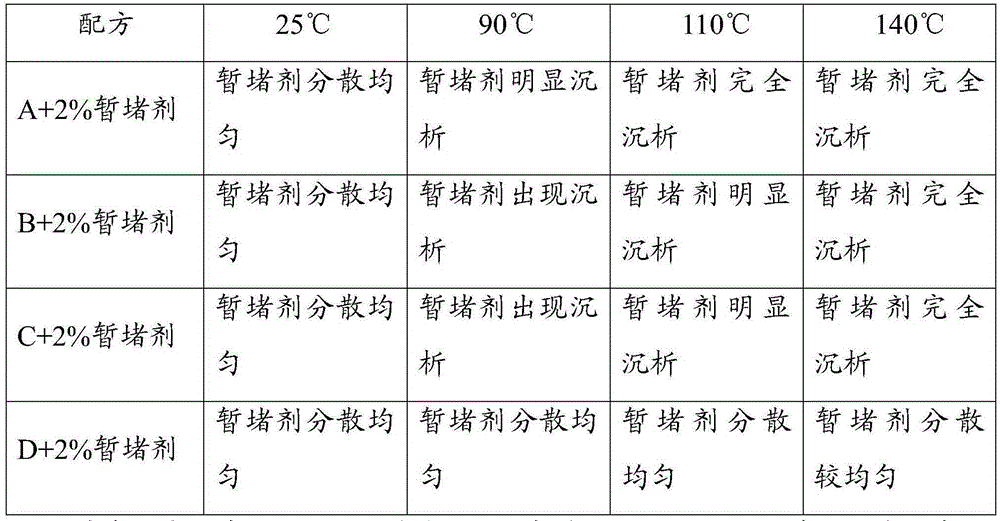

Examples

Embodiment 1

[0072] The temperature at the bottom of a certain well was 133°C, and sand was produced. The xanthan gum sand flushing fluid prepared by conventional methods could not carry the sand out smoothly. Take 95.65 parts of water and add it to the liquid mixing tank with agitator as the base liquid, add 3 parts of potassium formate and stir for 5 minutes; 10 to 20 minutes, the feeding speed and stirring time shall be subject to the full dissolution of xanthan gum; add 0.2 parts of thiourea and stir for 5 minutes; add 0.15 parts of fungicide and stir for 5 minutes; finally add 0.5 parts of ethylenic monomer polymer Stir for about 10 minutes until the solution is uniform to obtain the solution of the workover fluid viscosity enhancer described in the embodiment of the present invention.

[0073] 40 cubic meters of the above solution was transported to a well with a tank truck and used as a sand-carrying fluid. The bottom of the well was flushed with 35 meters of sand. The operation was...

Embodiment 2

[0075] The temperature at the bottom of a well was 137°C, and sand was produced. The xanthan gum sand flushing fluid prepared by conventional methods could not carry the sand out smoothly. Take 96.1 parts of water and add it into the liquid mixing tank with agitator as the base liquid, add 2 parts of potassium formate and stir for 5 minutes; 10 to 20 minutes, the feeding speed and stirring time shall be subject to ensuring that the xanthan gum is fully dissolved; add 0.2 parts of thiourea and stir for 5 minutes; add 0.2 parts of fungicide and stir for 5 minutes; finally add 1 part of ethylenic monomer polymer Stir for about 10 minutes until the solution is uniform to obtain the solution of the workover fluid viscosity enhancer described in the embodiment of the present invention.

[0076] 60 cubic meters of the above-mentioned solution was transported to a well (bottom hole temperature 137°C) by tank truck, and used as a sand-carrying fluid. The bottom-hole sand washing was 25...

Embodiment 3

[0078] The temperature at the bottom of a well was 135°C, and sand was produced. The xanthan gum sand flushing fluid prepared by conventional methods could not carry the sand out smoothly. Take 97.5 parts of water and add it to the liquid mixing tank with agitator as the base liquid, add 1 part of potassium formate and stir for 5 minutes; 10 to 20 minutes, the feeding speed and stirring time shall be subject to the full dissolution of xanthan gum; add 0.1 part of thiourea and stir for 5 minutes; add 0.1 part of fungicide and stir for 5 minutes; finally add 0.8 part of ethylenic monomer polymer Stir for about 10 minutes until the solution is uniform to obtain the solution of the workover fluid viscosity enhancer described in the embodiment of the present invention.

[0079] 40 cubic meters of the above solution was transported to a well (bottom hole temperature 135°C) by a tank truck, and used as a sand-carrying fluid. The bottom-hole sand washing was 25 meters, and the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com