Method for insulating anaerobic fermentation tank in solar pond

An anaerobic fermentation tank and solar pool technology, which is applied in the field of anaerobic reactors, can solve the problems of less research on heat preservation and the difficulty of popularizing heat preservation anaerobic reactors, etc., so as to reduce the cost of gas production and heat preservation, reduce flow, and save The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

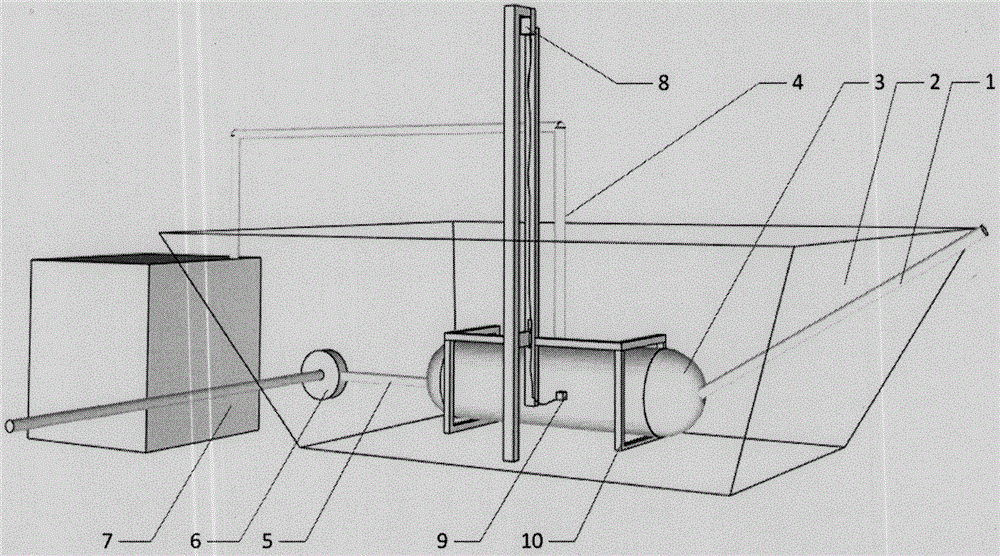

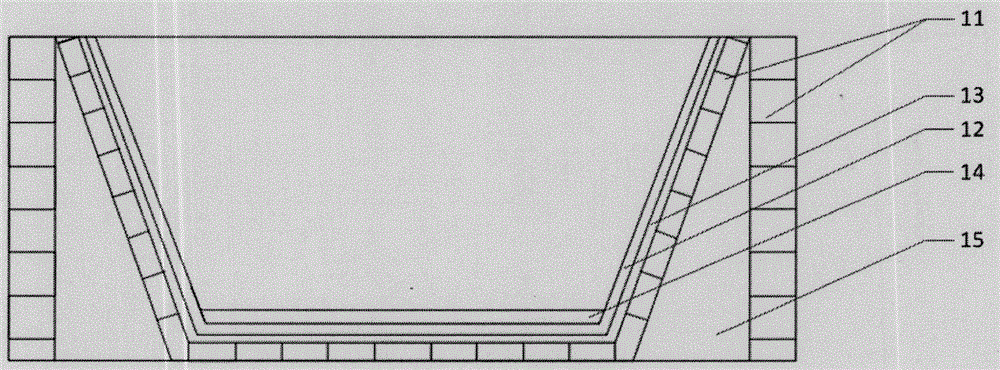

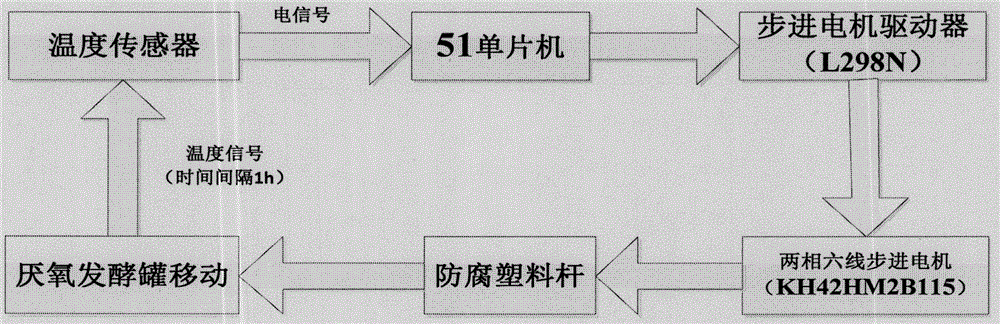

[0015] Embodiment: The present invention places the biogas fermentation device in the salt gradient solar pond 2, conducts heat transfer and heat preservation directly through the wall of the biogas tank, designs an automatic temperature tracking system in the salt gradient solar pond 2, and tracks the temperature suitable for microbial fermentation—— 35°C. Both the anaerobic fermentation tank 3 and the air outlet pipe 4 use PE plastic hoses, and the salt gradient solar pond 2 is composed of red bricks 11, extruded boards 12, cement layer 13, porous media 14 and fine sand 15. During the fermentation process, the feed liquid enters the anaerobic fermentation tank 3 from the feed inlet 1, and the produced biogas is stored in the gas storage bin 7 through the gas outlet pipe 4. After the fermentation is completed, start the pump 6 and discharge it through the outlet pipe 5 Most of the biogas slurry and residue. The tracking system controls the stepping motor through the single-c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap