Process method for plugging treatment of gas under pressure in blast furnace base sealing plate

A blast furnace and sealing plate technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as high gas volume around the furnace base, vicious accidents, safety accidents, etc., to eliminate hidden dangers of personal safety accidents, high integration Effects of Strength and Toughness and Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

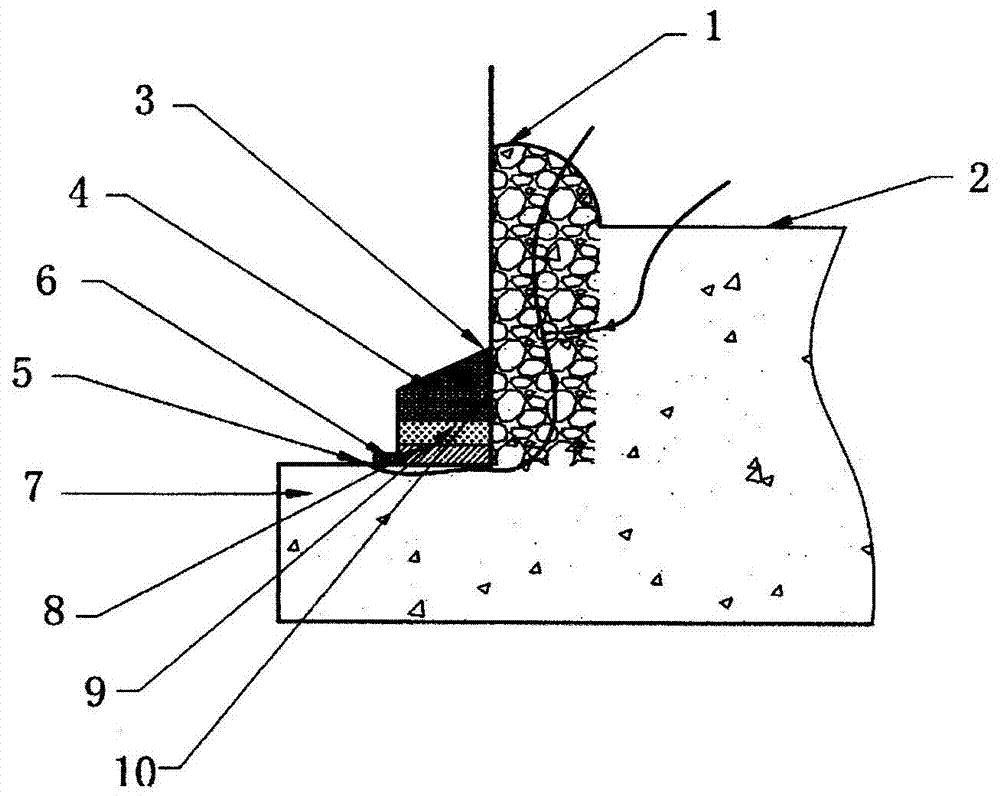

[0017] The technological method of the present invention for the plugging and treatment of the blow-by of the blast furnace base sealing plate and the gas under pressure is realized in this way, and will be described in detail with the accompanying drawings and examples below.

[0018] The process method of the present invention for sealing blow-by of the blast furnace foundation sealing plate with pressurized gas plugging and treatment uses three kinds of composite materials with different properties in the cavity of the furnace foundation sealing plate: solid special resin composite material, plastic special colloid material and high-strength casting The material is the plugging material; the solid special resin composite material adopts epoxy building structure resin glue; the plastic special colloid material adopts clear base binder, micropowder, anthracene oil, and thermosetting resin, and the weight ratio is 6:2:1:1 It is made of special colloidal material for composite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com