Temperature measurement at high-voltage potential

A high-voltage electricity, temperature measurement technology, used in thermometers, thermometers with directly sensitive electrical/magnetic components, and heat measurement, to achieve the effect of less energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

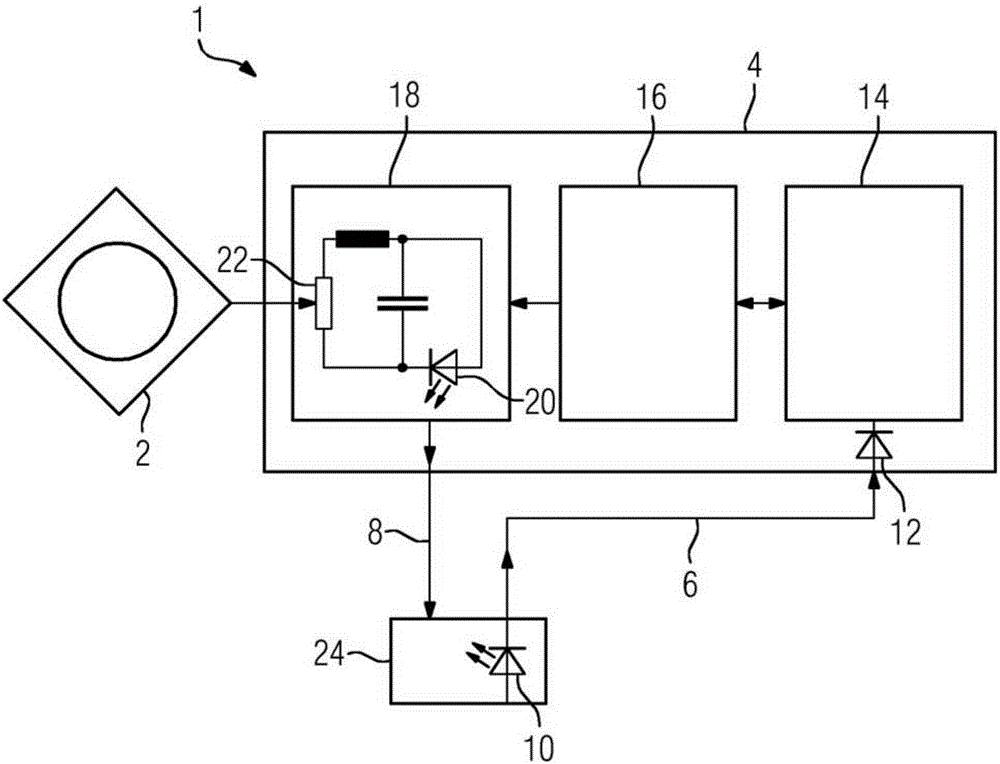

[0023] figure 1 Shown is a device 1 for temperature measurement at a high voltage potential, comprising an optical current transformer 2, an electronic temperature sensor 4, a first and a second optical waveguide 6, 8 and a first light emitting diode 10, which is located at ground Within station 24. In addition, the temperature sensor 4 includes exactly one photodiode 12 , a capacitor 14 , a control unit 16 and an oscillation circuit 18 . Furthermore, the second LED 20 and the temperature-sensing resistor 22 are located in the current loop of the oscillator circuit 18 . Here, the temperature sensing resistor 22 can be, for example, a thermistor, a PT100, a thermal element or a semiconductor sensor.

[0024] Light from the first light emitting diode 10 is conducted via the first optical waveguide 6 to the photodiode 12 in the electronic temperature sensor 4 . The optical waveguides 6, 8 may preferably be standard multimode optical waveguides or 200 / 220 μm Hard-Cladding-Silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com