Moisture-retaining agent improving physical moisture retaining performance of expanded tobacco and preparation method for moisture-retaining agent

A technology for moisturizing performance and expanding cut tobacco, applied in the field of tobacco, can solve problems such as rapid water loss, and achieve the effects of good compatibility, simple preparation process and good moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

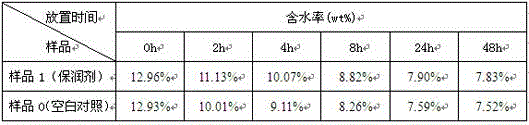

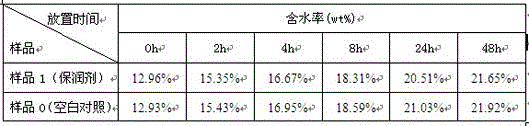

[0021] In a constant temperature and humidity chamber, set the temperature at (22±1)°C, respectively in a low-humidity environment with a relative humidity of (40±2)% and a high-humidity environment with a relative humidity of (75±2)%, through the oven method ( YC / T31-1996 "Preparation of Tobacco and Tobacco Products Samples and Determination of Moisture Oven Method") to calculate the initial moisture content of expanded cut tobacco, and use the difference method to calculate the instant moisture content of expanded cut tobacco. ratio of deionized water) to compare the instant moisture content, and evaluate the moisturizing effect of each moisturizer. The specific process is as follows:

[0022] (1) Prepare the humectant according to the weight percentage of sodium hexametaphosphate 6.25% and deionized water 93.75wt%.

[0023] (2) The humectant with the above ratio can be completely dissolved after ultrasonication for 5 minutes at room temperature and under the condition that ...

Embodiment 2

[0039] The preparation method of the humectant for improving the physical humectant performance of expanded shredded tobacco comprises preparing the humectant according to the weight percentage of potassium monohydrogen phosphate 9.375wt% and deionized water 90.625wt%. At 30°C, under the condition that the ultrasonic power is 100% of the rated power of the ultrasonic generator, potassium monohydrogen phosphate can be completely dissolved in deionized water after ultrasonication for 20 minutes.

Embodiment 3

[0041] The preparation method of the humectant for improving the physical humectant performance of expanded shredded tobacco comprises preparing the humectant according to the weight percentage of sodium dihydrogen phosphate 15wt% and deionized water 85wt%. At 35°C, under the condition that the ultrasonic power is 70% of the rated power of the ultrasonic generator, sodium dihydrogen phosphate can be completely dissolved in deionized water after ultrasonication for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com