Method for preparing novel super-hydrophobic polyurethane oil-water separation material with no solvent

An oil-water separation and super-hydrophobic technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as pollution, poor mechanical stability, and a large number of environments, and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017]

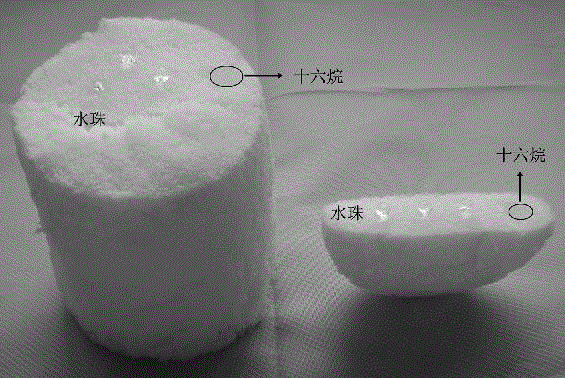

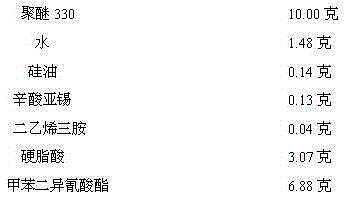

[0018] Weigh each component according to the above ratio, ultrasonically dissolve 2.11g of stearic acid in 10.00g of polyether 330, and dissolve 1.48g of water, 0.14g of silicone oil, and 0.13g of caprylic acid at a temperature of 35°C and a speed of 1000r / min. Add stannous and 0.04 g of diethylenetriamine to the above mixture and stir for 1 min. Quickly add 6.85g of toluene diisocyanate at 35°C, stir for 5s, transfer the reaction solution to a beaker, the foaming process begins, take it out after 10min and place it in a 60°C oven for 4h to obtain a superhydrophobic polyurethane foam . The surface contact angle of the obtained superhydrophobic polyurethane was 153.5°; the contact angle of oil (hexadecane) was 0°.

Embodiment 2

[0020]

[0021] Weigh each component according to the ratio described in the present invention, ultrasonically dissolve 3.07g stearic acid in 10.00g polyether 330, and dissolve 1.48g water, 0.14g silicone oil under the conditions of 40°C and 1200r / min at a temperature , 0.13 g of stannous octoate, and 0.04 g of diethylenetriamine were added to the above mixture and stirred for 3 min. When the temperature is 40°C, 6.88g of toluene diisocyanate is quickly added, and after stirring for 5s, the reaction solution is transferred to a beaker, and the foaming process begins. After 10 minutes, it is taken out and placed in an oven at 50°C for 4 hours to obtain superhydrophobic Polyurethane foam. The surface contact angle of the obtained superhydrophobic polyurethane was 157.5°; the contact angle of oil (hexadecane) was 0°.

Embodiment 3

[0023]

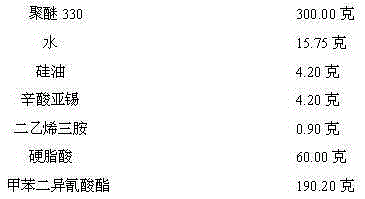

[0024] Weigh each component according to the ratio described in the present invention, ultrasonically dissolve 60.00g of stearic acid in 300.00g of polyether 330, and dissolve 15.75g of water and 4.20g of silicone oil at a temperature of 30°C and a speed of 1000r / min. , 4.20 stannous octoate, 0.9 g diethylenetriamine were added to the above mixture and stirred for 5 min. When the temperature is 30°C, 190.20g of toluene diisocyanate is quickly added, and after stirring for 10s, the reaction solution is transferred to a beaker, and the foaming process begins. After 15 minutes, it is taken out and placed in an oven at 50°C for 6 hours to obtain superhydrophobic Polyurethane foam. The surface contact angle of the obtained superhydrophobic polyurethane was 154.0°; the contact angle of oil (hexadecane) was 0°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com