Preparation method and device for powdery fatty acid methyl ester sodium sulfonate

A technology for preparing sodium fatty acid methyl ester sulfonate and equipment, which is applied in the field of hot air drying to prepare powdered sodium fatty acid methyl ester sulfonate, which can solve the problems of inconsistency between particles and washing powder particles, large fluctuations in product quality, and affecting washing effect, etc., to achieve Conducive to daily maintenance, low production cost, and increased product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

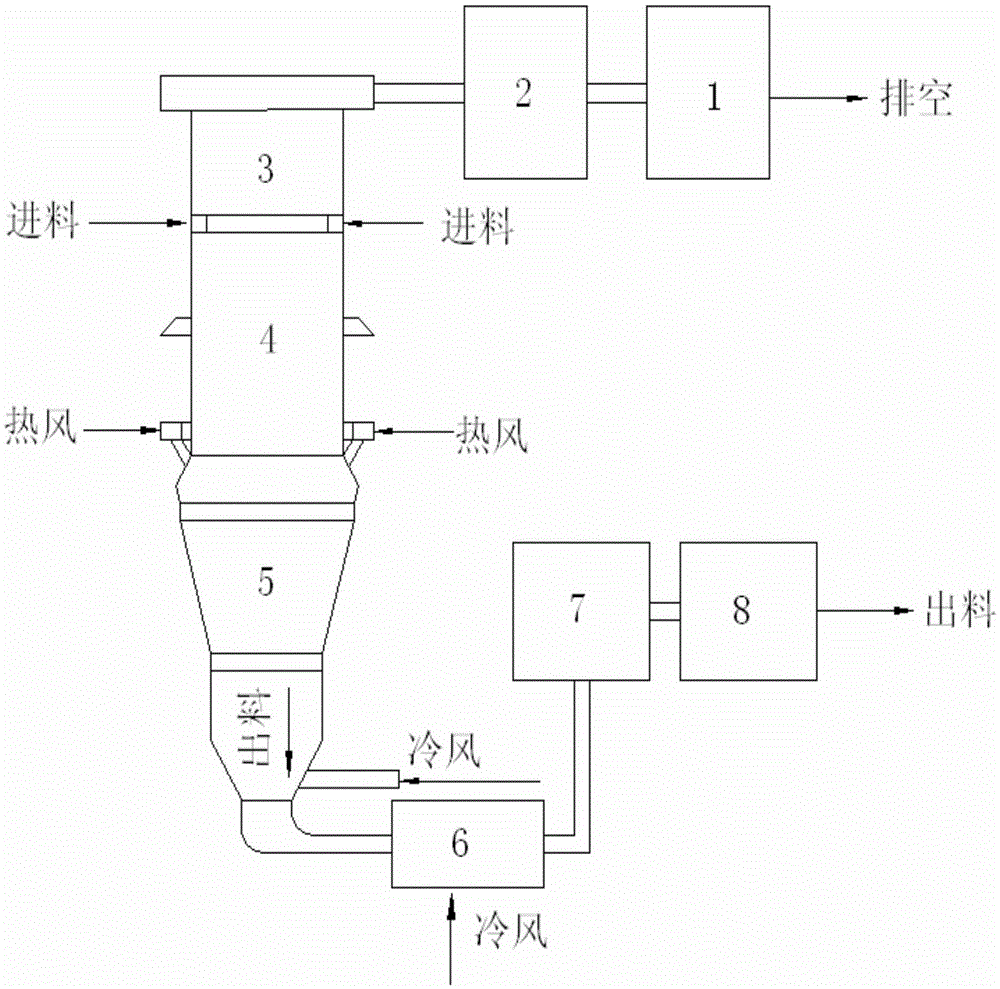

[0027] In the preparation device provided by the present invention, the drying tower (ie, the hot air drying tower) is designed as three functional sections arranged from top to bottom, namely the settling section 3 , the drying section 4 and the cooling section 5 . The drying section mainly realizes the drying of MES materials. The moisture content of the dried MES is less than 3%, and it falls to the cooling section under the action of gravity; the cooling section can quickly cool the materials to ensure that the temperature of the dried powdered MES when it leaves the drying tower is lower than 40℃, keep solid and not stick together; the designed settling section can minimize the material entrained in the dried hot air tail gas and increase the product yield; the hot air tail gas goes up through the exhaust port at the top of the settling section , and then pass through the cyclone separator 2 and the bag filter 1 in turn.

[0028] The material inlet is between the settling...

Embodiment 1

[0034] The material with MES content of 30% is preheated to a temperature of 50 ℃ ~ 60 ℃ with a coil heater, transported to the atomizer by a pump, and atomized by the atomizer into the drying section of the drying tower; the temperature of 200 ℃ ~ 250 ℃ The hot air enters the drying tower through multiple inlets arranged in a ring, and is in countercurrent contact with the atomized material for drying; after drying, the material enters the cooling section of the drying tower downward, and contacts with the cold air at the bottom of the drying tower with a temperature of 25°C to 30°C. Cool down to a temperature of ≤39°C, the material continues downwards, and comes out from the bottom of the drying tower into the fluidized bed for further cooling to below 28°C, and then the cold air is transported to a high-speed hammer mill to obtain powdered MES, moisture content: 2.8%, Apparent density: 269g / L.

Embodiment 2

[0036] The material with MES content of 55% is preheated to a temperature of 55 ℃ ~ 65 ℃ with a jacket heater, transported to the atomizer by a pump, and atomized by the atomizer into the drying section of the drying tower; the temperature is 170 ℃ ~ 210 ℃ The hot air enters the drying tower through a plurality of annularly arranged inlets, and is in countercurrent contact with the atomized material for drying; after drying, the material enters the cooling section of the drying tower downward, contacts with the cold air at the bottom of the drying tower with a temperature of 20 °C, and is rapidly cooled to 20°C. When the temperature is lower than 30°C, the material continues downward, and comes out from the bottom of the drying tower into the fluidized bed for further cooling until the temperature is lower than 25°C, and then the cold air is transported to the high-speed hammer mill to obtain powdery MES, moisture content: 2.2%, Apparent density: 356g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com