Preparation method of crosslinked polyglutamic acid hydrogel

A technology of polyglutamic acid and hydrogel, which is applied in the field of low-concentration cross-linked polyglutamic acid hydrogel and its preparation, can solve the problems of inaccurate dosage, uneven distribution, instability, etc. The content is stable and consistent, and the effect of easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

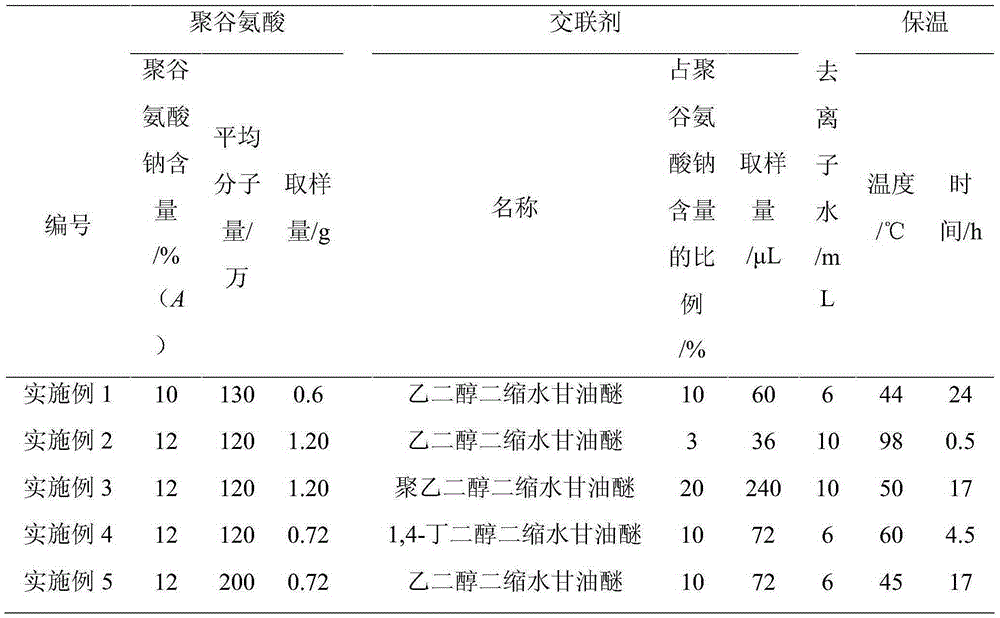

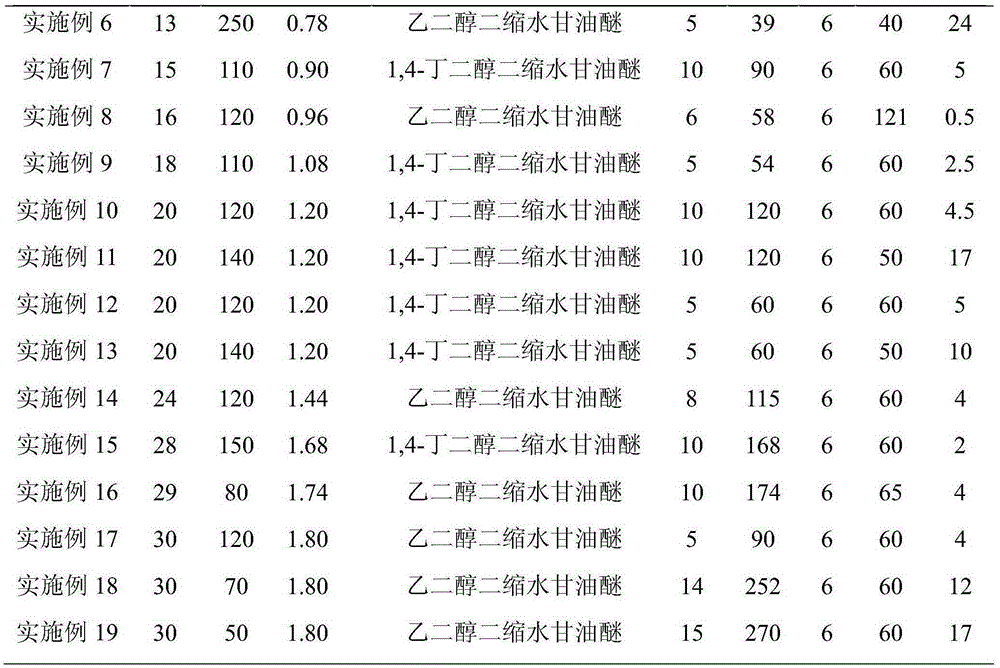

[0029] Table 1 Preparation of high-concentration cross-linked polyglutamic acid gel blocks

[0030]

[0031]

[0032] Preparation method of high-concentration cross-linked polyglutamic acid gel blocks: According to the data in Table 1, a certain amount of sodium polyglutamate and cross-linking agent were dissolved in deionized water, stirred and mixed, and kept in a water bath for a period of time to obtain a non-flowing High-concentration cross-linked polyglutamic acid gel blocks.

[0033] According to Table 2, stable uniformly dispersed low-concentration cross-linked polyglutamic acid hydrogels were prepared respectively.

[0034] Table 2 Stable uniformly dispersed low-concentration cross-linked polyglutamic acid hydrogel

[0035]

[0036]

[0037] Stable uniformly dispersed low-concentration cross-linked polyglutamic acid hydrogel preparation method: According to the data in Table 2, weigh a certain mass of high-concentration cross-linked polyglutamic acid gel ...

experiment example

[0039] 1. Stability test: the cross-linked polyglutamic acid hydrogel was left standing for 10 months

experiment example 1

[0041] Experimental Example 1 Dissolve 4.0 g of sodium polyglutamate with an average molecular weight of 1.2 million and 40 μL of 1,4-butanediol diglycidyl ether in 50 mL of deionized water, stir and mix, and keep warm in a water bath at 60 ° C for 4 hours to obtain a fluid State cross-linked polyglutamic acid (polyglutamic acid content 8%, 1,4-butanediol diglycidyl ether accounts for 1% by weight of polyglutamic acid). Inhomogeneous precipitates can be seen when stirred, and dark yellow precipitates are deposited at the bottom after a long period of storage. After stirring and mixing, absorb 4.2376g of the glue, in order to obtain a cross-linked polyglutamic acid hydrogel with a cross-linked polyglutamic acid content of 0.21%, calculate and add 161mL of deionized water, and homogenize in a crushing homogenizer, A dispersed cross-linked polyglutamic acid hydrogel was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com