High-temperature-resistant honeycomb briquette

A technology of high temperature resistance and honeycomb coal, applied in the field of honeycomb coal, can solve the problems of high production cost, complex raw material composition, easy melting at high temperature, etc., and achieve the effects of high viscosity, improved appearance quality, and good shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

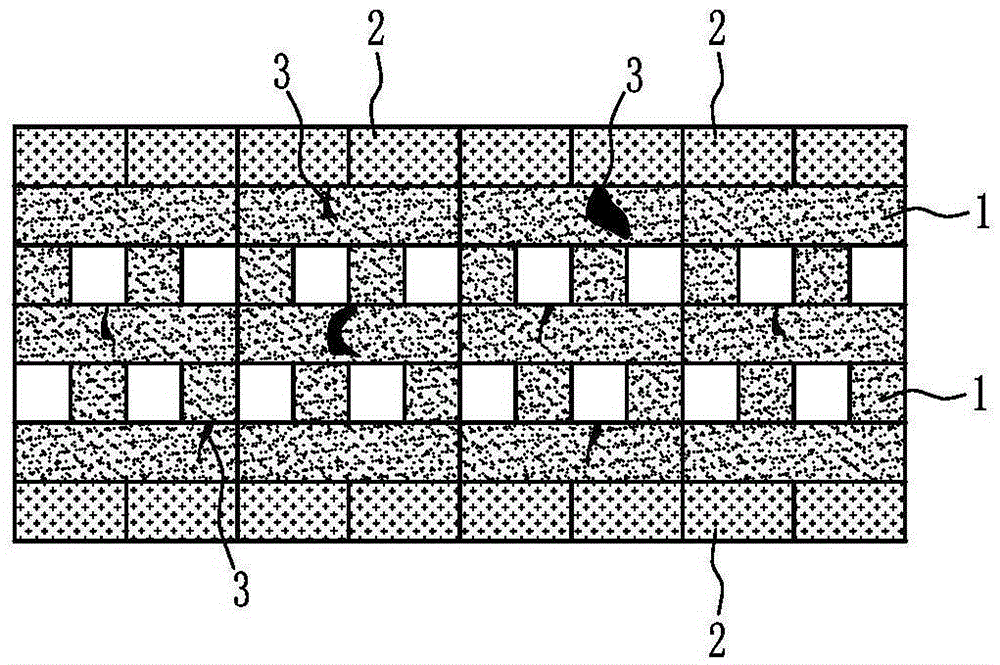

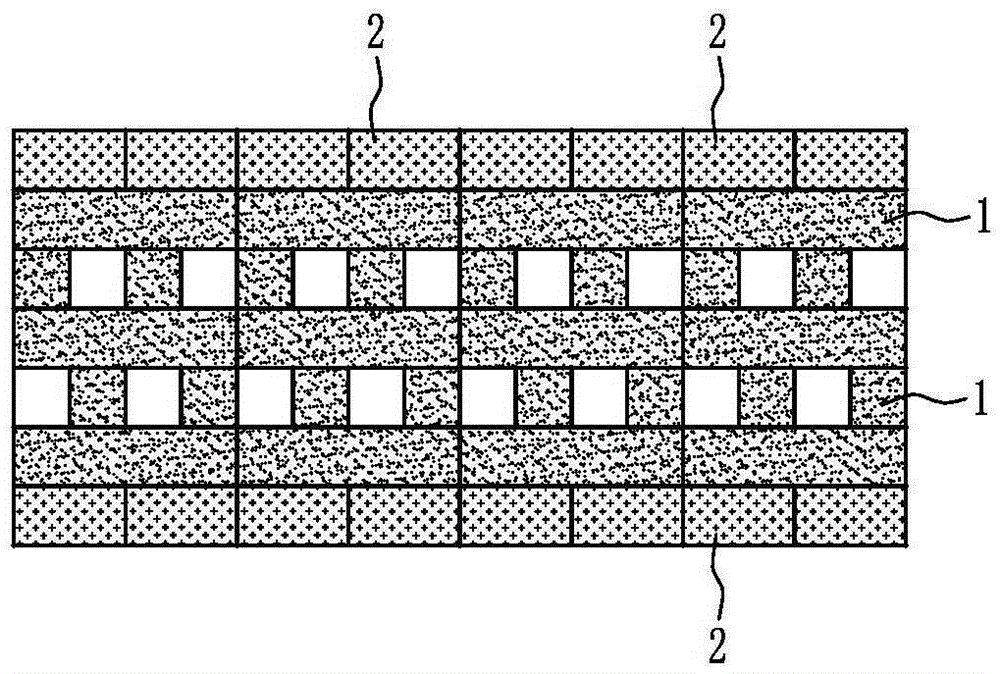

Image

Examples

Embodiment 1

[0027] The high-temperature-resistant honeycomb coal includes coal powder, clay and kaolin, the mass ratio of the coal powder and the clay is 100:30, and the mass content of the kaolin is 20-30% of the clay. The main mineral component in the kaolin is kaolinite, and its crystal chemical formula is 2SiO 2 .Al 2 O 3 .2H 2 O.

Embodiment 2

[0029] The high-temperature-resistant briquettes include coal powder, clay and kaolin, the mass ratio of the coal powder and the clay is 100:30, and the mass content of the kaolin is 30-40% of the clay. The main mineral component in the kaolin is kaolinite, and its crystal chemical formula is 2SiO 2 .Al 2 O 3 .2H 2 O.

Embodiment 3

[0031] The high-temperature-resistant briquettes include coal powder, clay and kaolin, the mass ratio of the coal powder and the clay is 100:32, and the mass content of the kaolin is 40-50% of the clay. The main mineral component in the kaolin is kaolinite, and its crystal chemical formula is 2SiO 2 .Al 2 O 3 .2H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com