Efficient production method for cellulase

A technology of cellulase and streak inoculation, applied in the field of fermentation engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

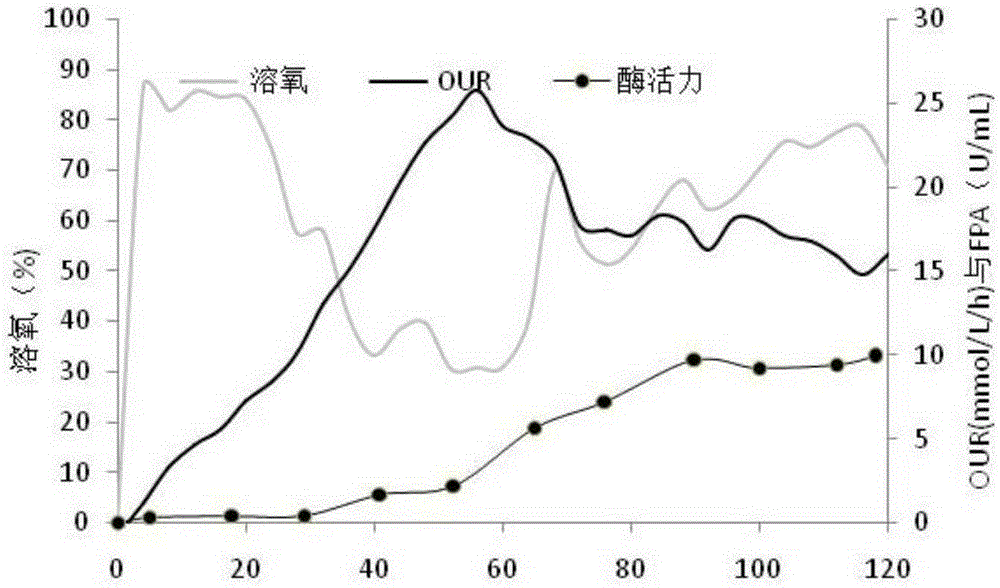

Embodiment 1

[0041] Seed medium: 1% xylose residue, 1% bran, 1% glucose, 1% peptone, 0.2% ammonium sulfate, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 50mL in a 500mL Erlenmeyer flask, extinguished at 121°C Bacteria 20min.

[0042] Enzyme production medium: 3% xylose residue, 3% bran, 0.2% microcrystalline cellulose, 0.5% bean cake powder, 0.2% ammonium sulfate, 0.1% urea, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.3 % Tween 80, sterilized at 121°C for 30min.

[0043] Filter paper enzyme (FPA) enzyme activity determination method: the fermentation broth was centrifuged at 8000rpm for 10min, and the supernatant was taken as crude enzyme solution for the determination of enzyme activity and protein content. Refer to the light industry industry standard (QB2583-2003) for determination, take 0.5mL of appropriately diluted crude enzyme solution, use 50mg (1cm×6cm) Xinhua filter paper strips as substrate, add 1.5mL and 0.5mL of pH4.8 acetate buffer, Taki...

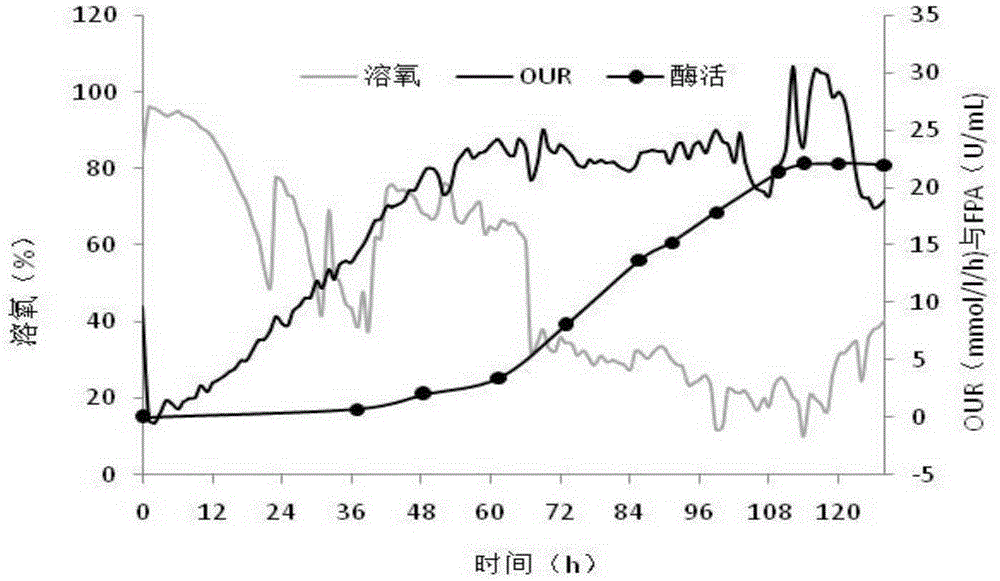

Embodiment 2

[0048] Seed medium: 1% xylose residue, 1% bran, 1% glucose, 1% peptone, 0.2% ammonium sulfate, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 50mL in a 500mL Erlenmeyer flask, extinguished at 121°C Bacteria 20min.

[0049] Enzyme production medium: 6% xylose residue, 4% bran, 0.2% microcrystalline cellulose, 0.5% bean cake powder, 0.2% ammonium sulfate, 0.1% urea, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.3 % Tween 80, sterilized at 121°C for 30min.

[0050] The filter paper enzyme (FPA) enzyme activity assay method and Bradford assay protein content were as described above.

[0051] Penicillium oxalicum JUA10-1 was streak-inoculated in bran medium and cultured at 30°C for 5 days. After the pink spores grew, it was transferred to fresh bran medium and cultured for 5 days as the strain. Connect 2cm 2 The strains were inoculated in the seed medium, fermented at 28-32°C and 200rpm for 24-48h, and prepared into first-grade seeds, and inocula...

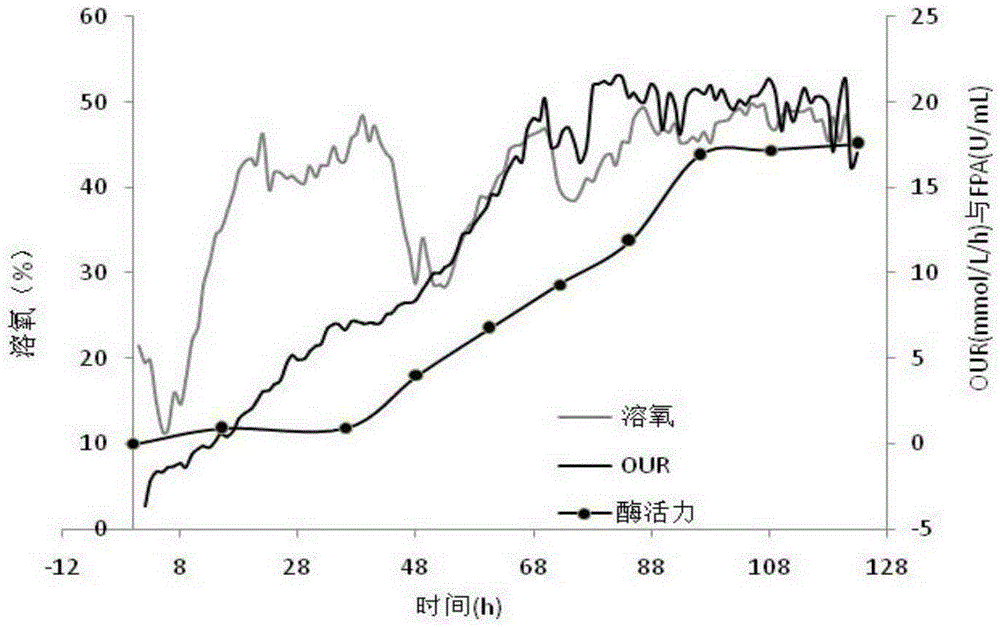

Embodiment 3

[0054] Seed medium: 1% xylose residue, 1% bran, 1% glucose, 1% peptone, 0.2% ammonium sulfate, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 50mL in a 500mL Erlenmeyer flask, extinguished at 121°C Bacteria 20min.

[0055] Enzyme production medium: 6% xylose residue, 4% bran, 0.2% microcrystalline cellulose, 0.5% bean cake powder, 0.2% ammonium sulfate, 0.1% urea, 0.3% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.3 % Tween 80, sterilized at 121°C for 30min.

[0056] The filter paper enzyme (FPA) enzyme activity assay method and Bradford assay protein content were as described above.

[0057] Penicillium oxalicum JUA10-1 was streak-inoculated in bran medium and cultured at 30°C for 5 days. After the pink spores grew, it was transferred to fresh bran medium and cultured for 5 days as the strain. Connect 10cm 2 The strain is inoculated in the seed medium, fermented at 28-32°C and 200rpm for 24-48h, and prepared into first-grade seeds, inoculated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com