Gas forced circulation waste heat boiler

A forced circulation, waste heat boiler technology, applied in lighting and heating equipment, steam generation methods, steam generation and other directions, can solve the problems of small contact area of the riser, unsatisfactory furnace insulation effect, unsatisfactory heat absorption, etc. Heat recovery rate, shorten the contact distance, and realize the effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

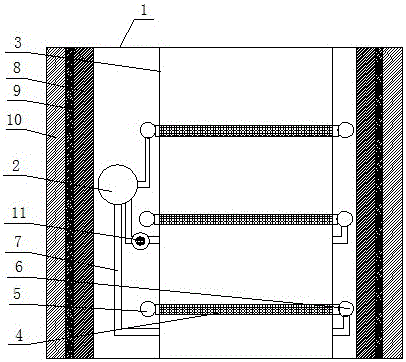

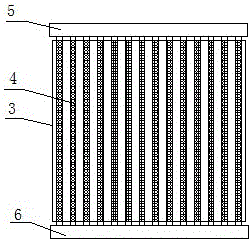

[0016] A gas forced circulation waste heat boiler, such as figure 1 , including furnace body 1, steam drum 2, circulation pump 11, gas channel 3, heating surface assembly, downcomer 7, steam drum 2 and gas channel 3 are located in furnace body 1, and steam drum 2 is located in the gas channel 3 On the side, the heating surface assembly is respectively provided with a water inlet pipe and a steam outlet, and the steam drum 2 is provided with a steam-water separator. In the gas channel 3, the heating surface assembly is connected to the inlet of the steam-water separator through a pipeline, such as figure 2 , the heating surface assembly includes a tube group, a left header 5, and a right header 6. The tube group includes a number of water pipes 4, and the two ends of the water pipe 4 are respectively connected to the left header 5 and the right header 6. The outer surface of the water pipe 4 is provided with a honeycomb structure formed by several grooves, and the furnace bod...

Embodiment 2

[0020] The structure of the second embodiment is basically the same as that of the first embodiment. The difference between the second embodiment and the first embodiment is that the water pipe 4 and the water pipe 4 are also provided with a spiral thin steel strip.

Embodiment 3

[0022] The structure of the third embodiment is basically the same as that of the first embodiment, and the difference between the third embodiment and the first embodiment is that: the water pipe 4 is also provided with a sawtooth piece, and the sawtooth piece is formed in a spiral shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com