Helium groove of compound superconducting solenoid magnet coil

A technology of magnet coils and solenoids, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of poor uniformity of the magnetic field of superconducting magnets, unsatisfactory assembly accuracy, and large internal structural stress, etc., to achieve Avoid the effects of unable to perform normal welding, easy to guarantee processing accuracy, and small welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the best examples shown in the accompanying drawings for further details:

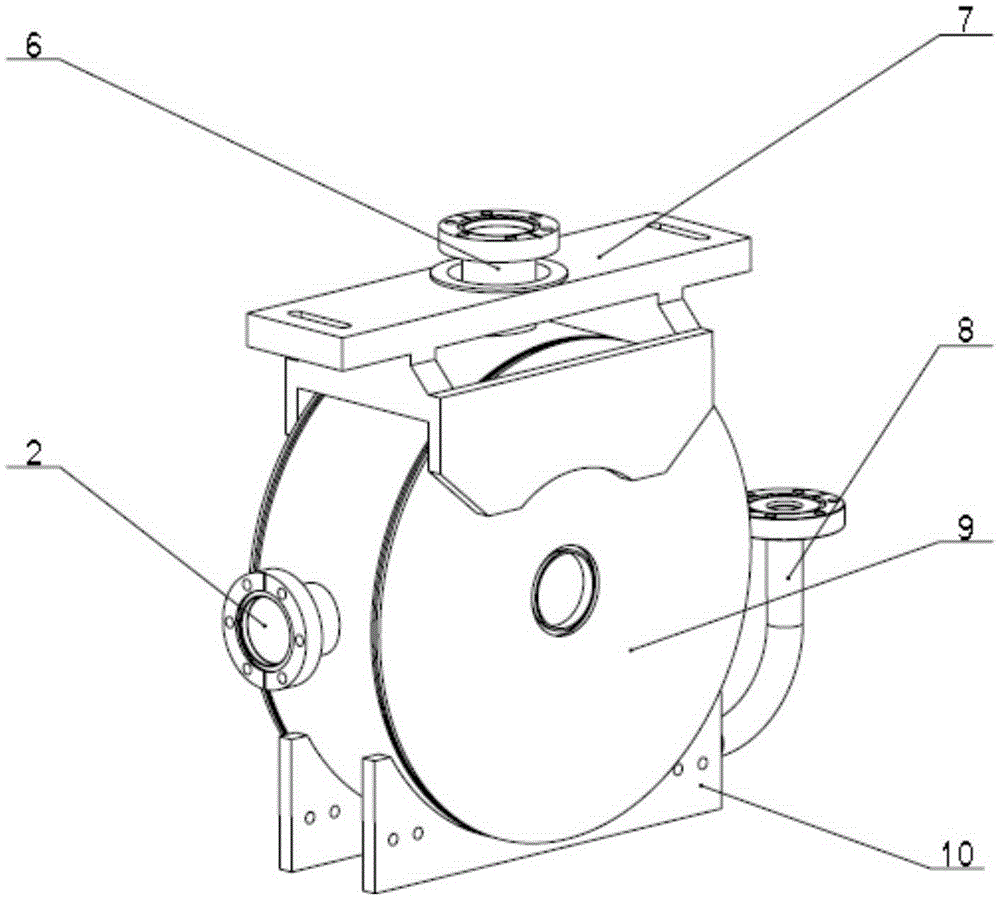

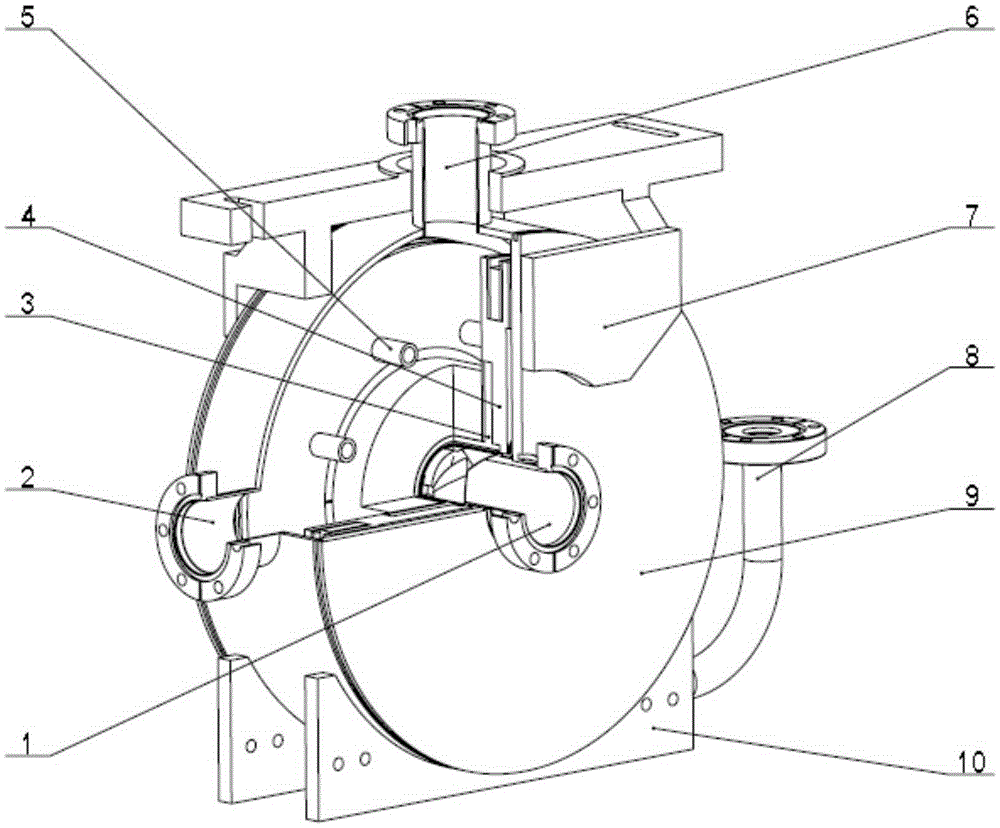

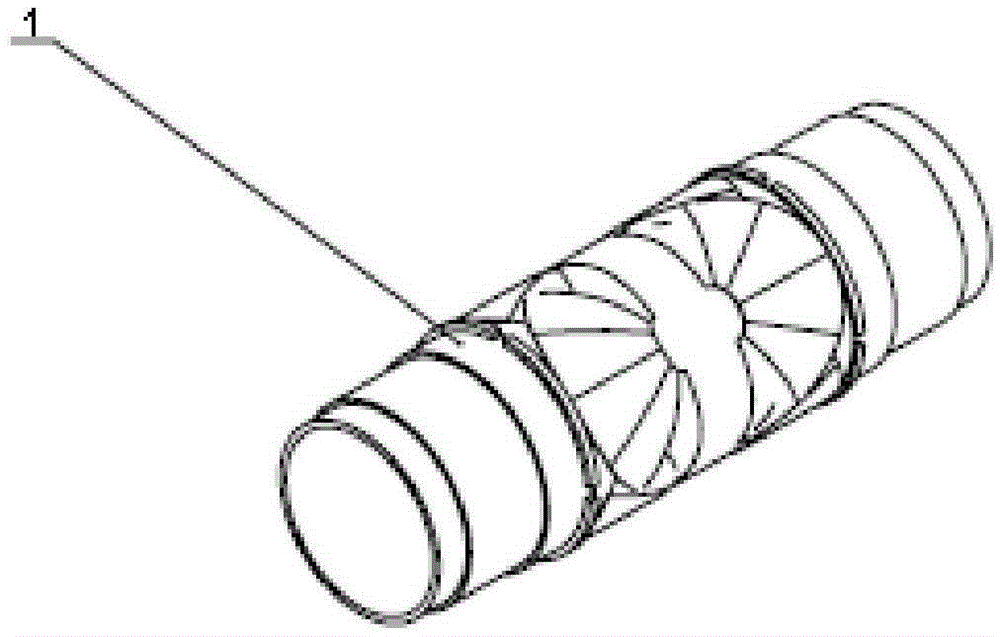

[0019] Such as Figures 1 to 4 As shown, the described composite superconducting solenoid magnet coil helium tank is characterized in that it includes a superconducting solenoid magnet coil frame encapsulated in the helium tank, and the superconducting solenoid The magnet bobbin includes a beam channel tube 1 that doubles as two pairs of racetrack-shaped coil bobbins, horizontal and vertical. The beam channel tube 1 is covered with a main magnetic field coil bobbin 3, and the two ends of the main magnetic field coil bobbin 3 are set There are two shielding magnetic field coil bobbins 4, a spacer tube 5 is correspondingly arranged between the main magnetic field coil bobbin 3 and the shielding magnetic field coil bobbin 4, and a helium tank end plate 9 is arranged on the outside of the shielding magnetic field coil bobbin 4, and on the helium tank A liquid helium outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com