MTPA control method of built-in PMSM and MTPA control system

A technology of permanent magnet synchronous motor and control method, applied in control system, vector control system, motor generator control and other directions, can solve the problems of low efficiency and precision, and achieve the goal of improving efficiency, shortening the length of search interval, and improving test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

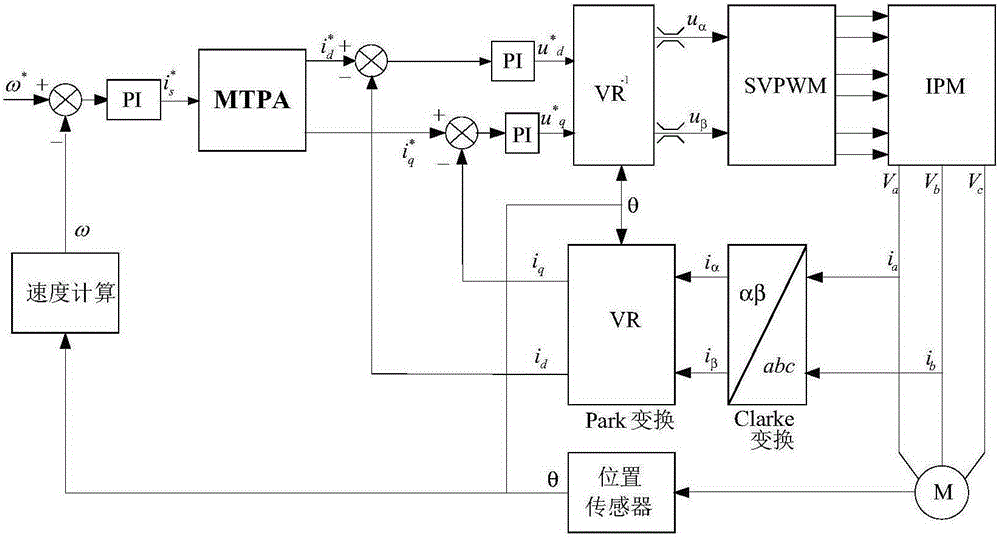

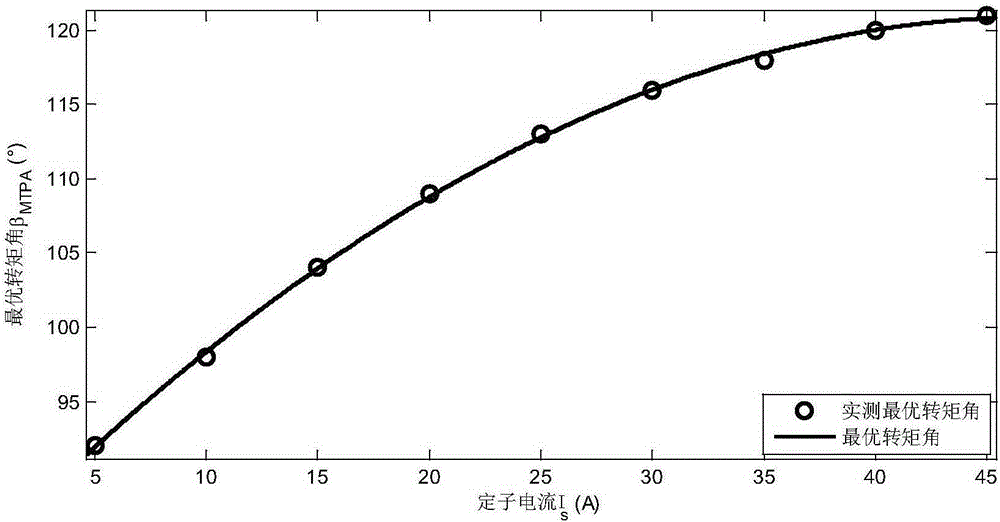

[0033] In order to solve the problem of low efficiency and precision of the existing MTPA algorithm of the built-in permanent magnet synchronous motor, the present invention proposes an MTPA experimental method based on variable interval search and binary quadratic polynomial fitting to achieve higher efficiency and precision MTPA algorithm. The experimental method is a general term, which is different from the theoretical formula method and the simulation method. For example, the document 2 mentioned in the background technology adopts an experimental method based on another mechanism. The present invention proposes a new variable interval search method , improve the efficiency of the MTPA algorithm, combined with binary quadratic polynomial fitting, to solve the problems of the prior art. Bivariate quadratic polynomial fitting is a basic mathematical method and will not be described in detail.

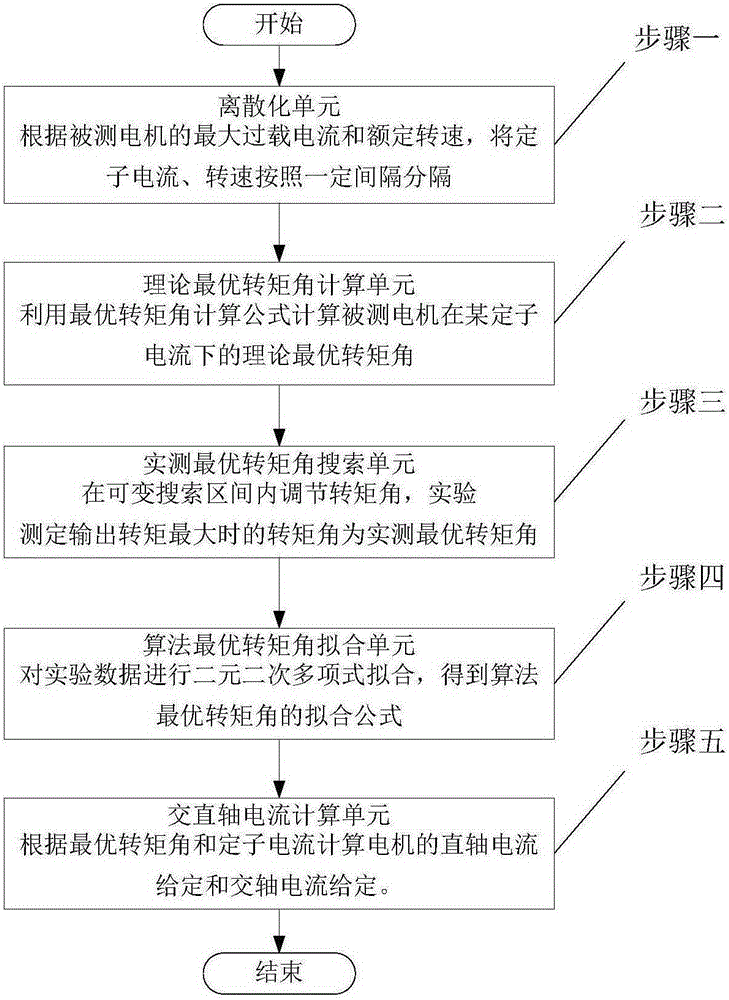

[0034] The present invention comprises the following steps:

[0035] Step 1: D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com