Drum screening machine for screening out nickel residual anodes

A technology of drum screening machine and nickel residue, which is applied in the direction of filter screen, solid separation, grid, etc., and can solve the problems of corrosiveness, high labor intensity, and inability to screen out anode slime and anode slime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

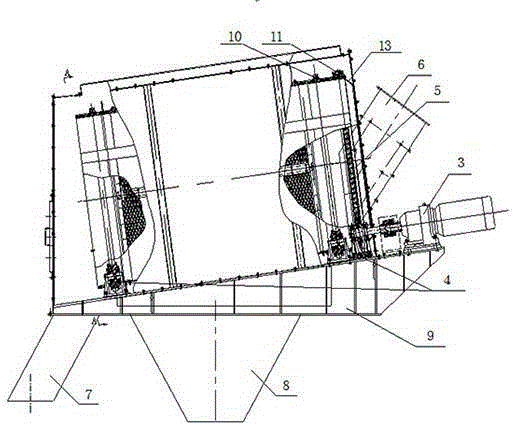

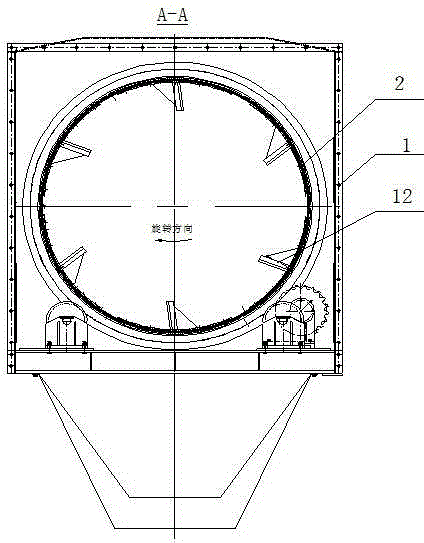

Method used

Image

Examples

example

[0032] The characteristics of the raw materials used in the present invention:

[0033] The anode slime is attached to both sides of the residual electrode plate, and two U-shaped copper wires are inserted into the head of each residual electrode. The thickness of anode slime is 4~6mm, chemical composition: elemental sulfur; moisture: 10~25%, showing acidity; specific gravity of pile: 0.6t / m3; chemical composition of nickel residue: Ni3S2>90%, single side length: ≤350mm, Bulk specific gravity: 3.0t / m3; copper wire diameter 5mm, length 250mm.

[0034] The production and implementation results of the invention: the daily processing of nickel residue is 100-120 tons, and the removal rate of anode slime is more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com