Oil-gas mixing injection, lubricating and milling technology for high-intensity steel aerospace structure

A technology of aviation structural parts, oil and gas mixing, applied in milling machine equipment, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of unstable built-up edge, environmental pollution, difficult recovery and treatment of mineral oil, etc. effect, the effect of reducing the built-up edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

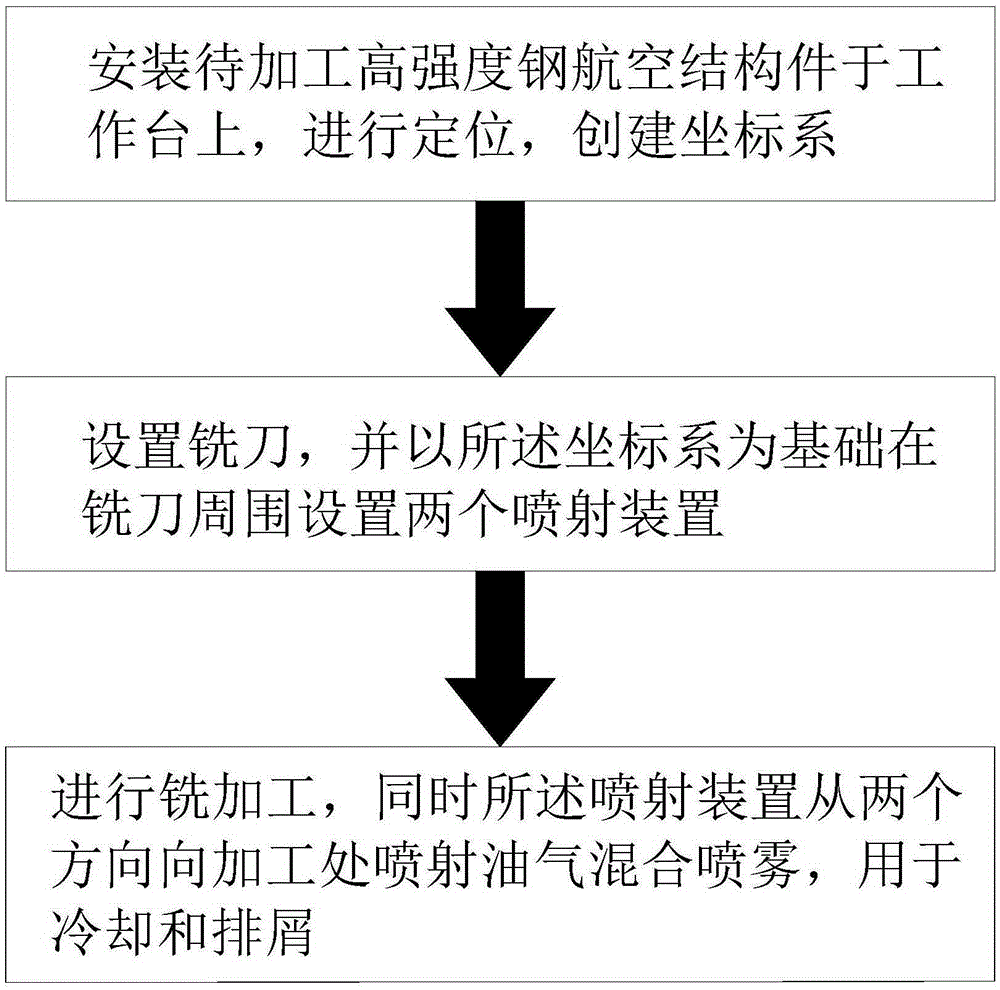

[0033] Such as figure 1 , a high-strength steel aerospace structural parts oil-air mixed jet lubrication milling technology, the steps are:

[0034] A. Install the high-strength steel aerospace structural parts to be processed on the workbench, perform positioning, and create a coordinate system;

[0035] B. The milling cutter is set, and two injection devices are arranged around the milling cutter based on the coordinate system, and the two injection devices are symmetrically distributed adjacent to each other;

[0036] C. Carry out milling, and at the same time, the injection device sprays oil-air mixed spray from two directions to the processing place for cooling and chip removal. The spray temperature is less than -5 °. In the oil-air mixed spray, the flow rate of oil is 10- 14ml / h.

[0037] In this embodiment, the injection device adopts a combination of a vortex tube and an oil dripping device, but the specific structure is not disclosed here. It is a brand-new struct...

Embodiment 2

[0042] In the present embodiment, except the technical scheme identical with embodiment 1, in step C, the flow rate of oil is 12-14ml / h.

[0043] In step B of this embodiment, when setting the milling cutter, it is different from the steps in embodiment 1. A rotating device (instead of the moving device) is provided on the spraying device to adjust the installation of a single spraying device. Angle, change the spray direction.

Embodiment 3

[0045] In the present embodiment, except the technical scheme identical with embodiment 1, in step C, the flow rate of oil is 10-12ml / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com