Optical glass softening furnace

An optical glass and softening furnace technology, applied in the field of softening furnaces, can solve the problems of energy waste, increased temperature, saving of unfavorable production resources and protection of human health, etc., and achieve the effect of reducing the temperature of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

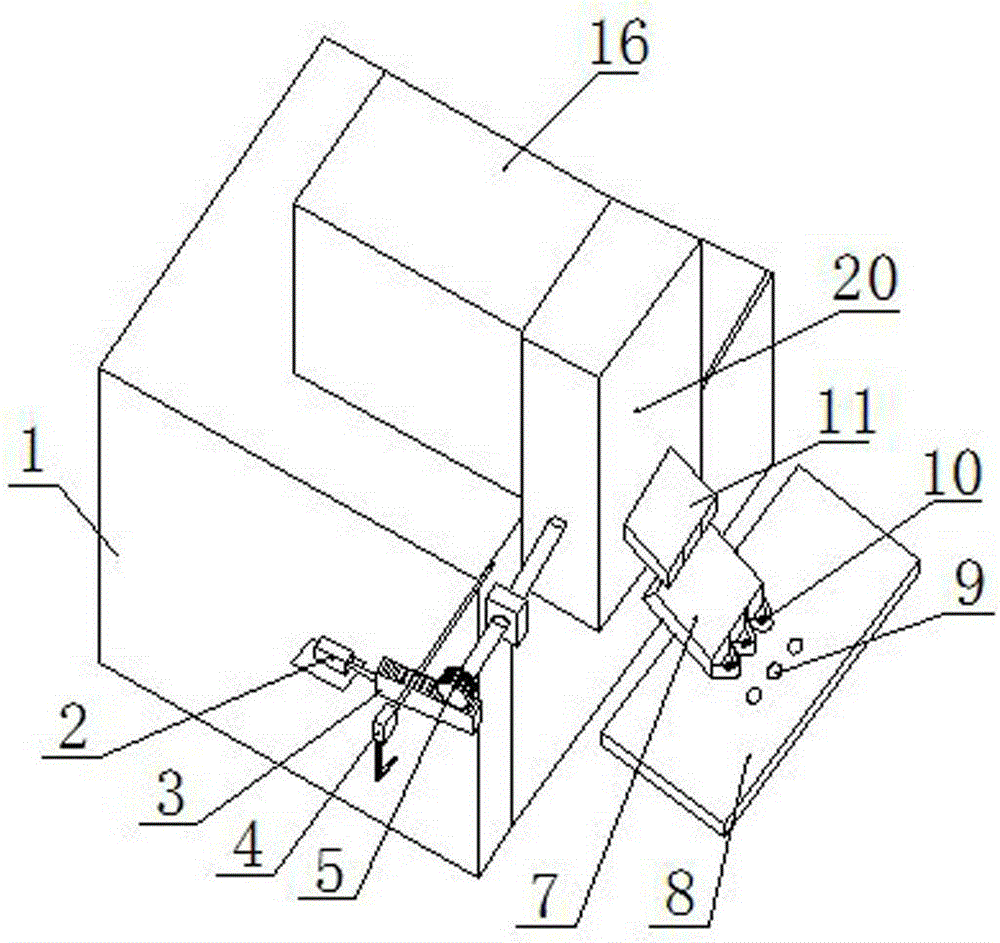

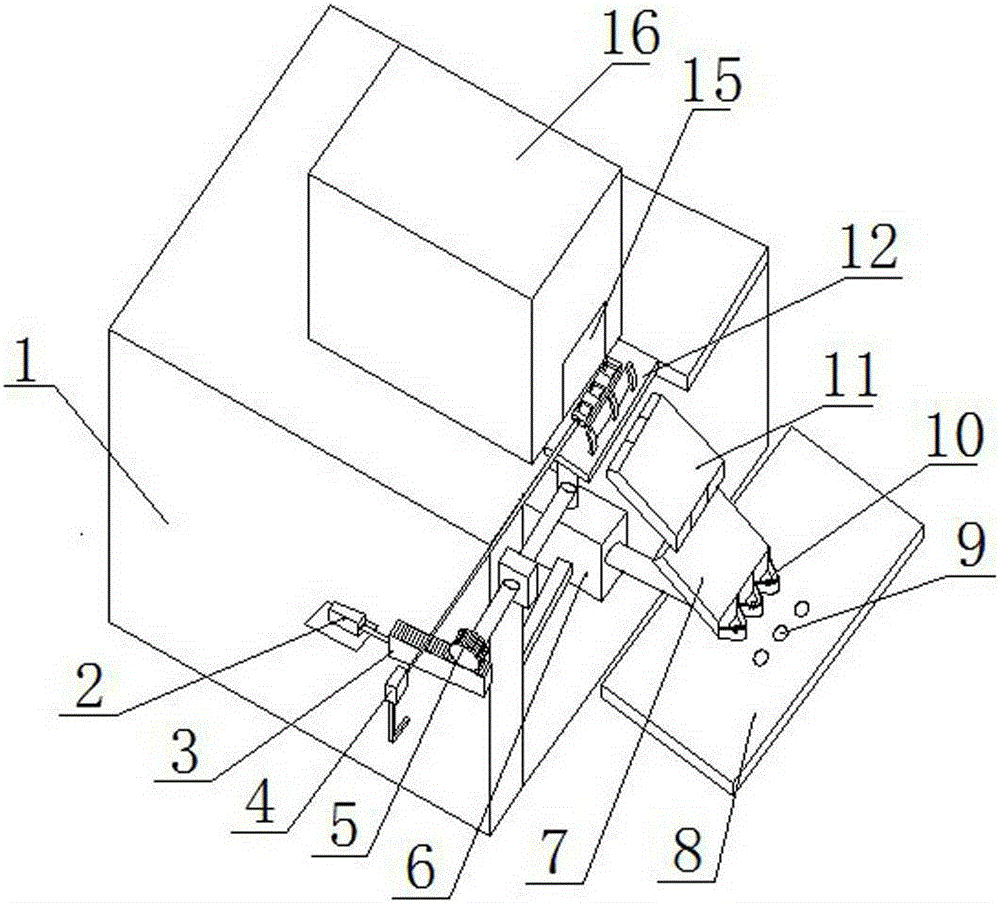

[0019] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

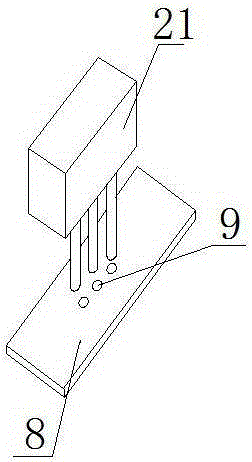

[0020] Figure 1-3 It shows an optical glass softening furnace provided by the present invention, including: base 1, cylinder 2, bar teeth 3, fourth conveying cylinder 4, roller teeth 5, pushing cylinder 6, second conveying channel 7, retaining ring 10. The first conveying channel 11, the turning mechanism 12, the softening furnace outlet 15, the softening furnace 16, the casing 20, the high temperature asbestos and the forming machine 21. The optical glass softening furnace includes an automatic conveying system, a base 1, a furnace body 16 arranged on the base, an automatic unloading device, and a first conveying channel 11 located below the automatic unloading device. The second delivery channel 7; the base 1 is provided with a push cylinder 6 along the outlet direction of the softening furnace 16, and the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com