Manganese gangue slag-based geopolymer cementing material and preparation method thereof

A technology of cementitious materials and tailings slag, applied in the field of manganese tailings slag base polymer cementitious materials and its preparation, to achieve the effects of improving comprehensive utilization, reducing costs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

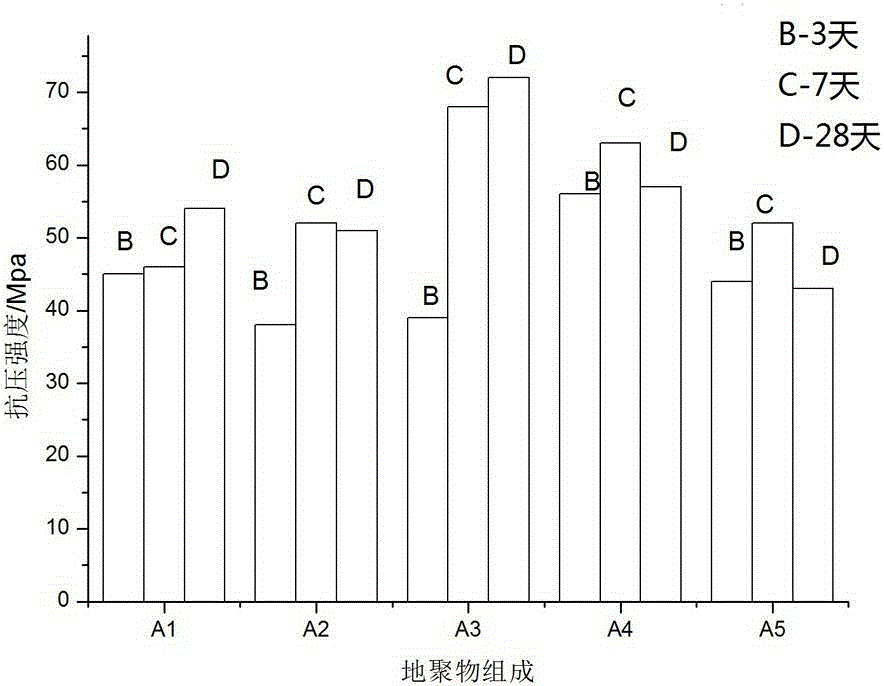

Image

Examples

Embodiment

[0020] (1) Preparation of metakaolin

[0021] Crush the kaolin, place it in a muffle furnace, raise the temperature to 600°C at a rate of 10°C / min, and keep it warm for 6 hours to obtain metakaolin with strong activity, and grind the obtained metakaolin with a sealed grinder Form into a fine powder with a particle size of 0.049-0.074mm.

[0022] (2) preparation of water glass solution

[0023] To 70.4mL, the modulus is 3.26, the degree of Baume is 39.7, ω(Na 2 O)=8.75%, ω(SiO 2 )=27.6%, adding 14.8 grams of sodium hydroxide in the commercially available technical grade water glass of density ρ=1.40g / mL is the water glass solution of 1.4 that makes modulus.

[0024] (3) Preparation of manganese tailings slag base polymer cementitious material

[0025] a. Put the manganese tailings slag in a sealed grinder, and grind it to a manganese tailings slag powder with a particle size of about 0.049-0.074mm.

[0026] B. be 30% according to the water glass solution dosage, the water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com