Anti-freezing anti-cracking anti-leaking mortar

An anti-leakage and mortar technology, applied in the field of building materials, can solve the problems of easy hollowing, easy leakage and easy cracking of sticking bricks, and achieves the effect of increasing adhesion, high viscosity and solving wall leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An antifreeze, anti-crack and anti-leakage mortar, made of the following raw materials in parts by weight: cement 20, medium and fine sand 50, waterproofing agent 1.0, tributyl phosphate 0.1, triethanolamine 0.1, high-strength and high-modulus polyvinyl alcohol fiber 0.3, 108 Glue 4, antifreeze 0.2, water 12.

[0019] The cement is ordinary Portland cement with a grade of 32.5. The fineness modulus of the medium-fine sand is 1.6-2.3.

[0020] The waterproofing agent is 777 waterproofing agent provided by Beijing Zhubao Technology Co., Ltd.; the high-strength and high-modulus polyvinyl alcohol fiber is produced by Changzhou Tianyi Engineering Fiber Co., Ltd.

[0021] The antifreeze is a mixture of calcium chloride and calcium nitrite (1:1).

[0022] The preparation method of described antifreeze anti-crack anti-leakage mortar comprises the following steps:

[0023] 1) Dry the medium-fine sand until the moisture content is below 0.5%, and screen out particles larger th...

Embodiment 2

[0028] An antifreeze, anti-crack and anti-leakage mortar, made of the following raw materials in parts by weight: cement 25, medium and fine sand 56, waterproofing agent 1.5, tributyl phosphate 0.25, triethanolamine 0.2, high-strength and high-modulus polyvinyl alcohol fiber 1.0, 108 6 parts of glue, 0.9 parts of antifreeze, and 13 parts of water.

[0029] The cement is ordinary Portland cement grade 42.5. The fineness modulus of the medium-fine sand is 2.0.

[0030] The waterproofing agent is 777 waterproofing agent provided by Beijing Zhubao Technology Co., Ltd.; the high-strength and high-modulus polyvinyl alcohol fiber is produced by Changzhou Tianyi Engineering Fiber Co., Ltd.

[0031] The antifreeze is a mixture of calcium chloride, urea, and ethylene glycol (1:1:1).

[0032] The preparation method of the antifreeze and anti-crack anti-leakage mortar is the same as that in Example 1.

Embodiment 3

[0034] An antifreeze, anti-crack and anti-leakage mortar, made of the following raw materials in parts by weight: cement 30, medium and fine sand 65, waterproofing agent 2.0, tributyl phosphate 0.3, triethanolamine 0.3, high-strength and high-modulus polyvinyl alcohol fiber 1.5, 108 Glue 6.5, antifreeze 1.4, water 15.

[0035] The cement is ordinary Portland cement with a grade of 32.5. The fineness modulus of the medium-fine sand is 2.3.

[0036] The waterproofing agent is 777 waterproofing agent provided by Beijing Zhubao Technology Co., Ltd.; the high-strength and high-modulus polyvinyl alcohol fiber is produced by Changzhou Tianyi Engineering Fiber Co., Ltd.

[0037] The antifreeze is a mixture of calcium chloride, urea, and ethylene glycol (1:1:1).

[0038] The preparation methods are all the same as in Example 1.

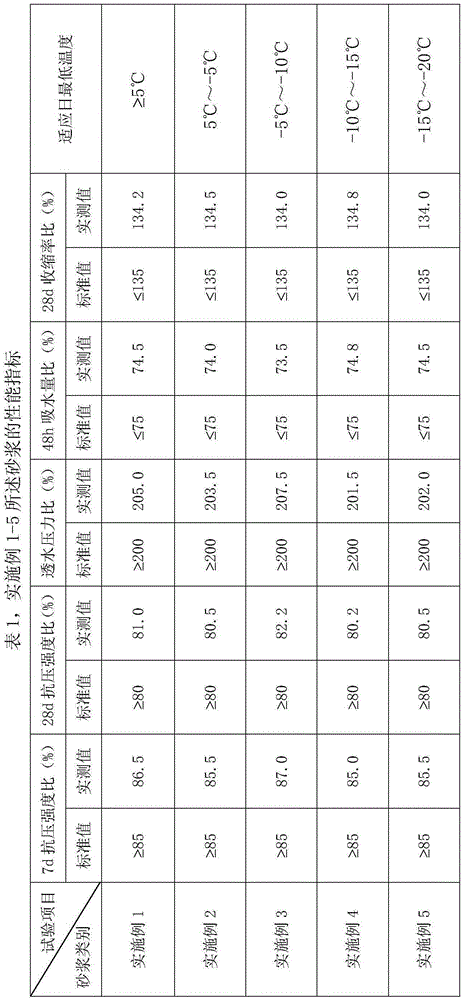

[0039] Determination of the performance indexes of the mortar described in Examples 1-5: compressive strength ratio, water permeability ratio, 48h water ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com