A process for recovering difluorodibromomethane from bromotrifluoromethane raffinate

A technology of difluorodibromomethane and trifluorobromomethane, which is applied in the field of ODS substitutes, can solve the problems of environmental pollution, high treatment costs, and low utilization rate of raw materials for recycling and utilization of useful substances, and achieves the effects of increasing economic benefits and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

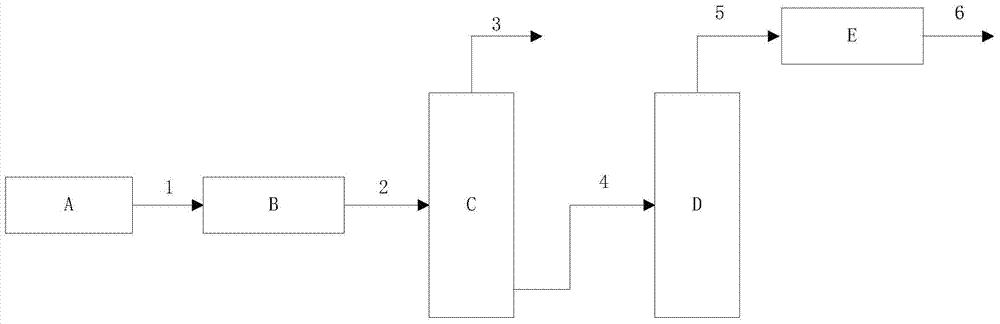

[0022] In the bromotrifluoromethane raffinate (1) obtained from the bromotrifluoromethane raffinate cylinder (A), the content of main components is 52% of difluorodibromomethane, 33% of difluorochlorobromomethane and 4% of difluorobromomethane. Pass the bromotrifluoromethane raffinate (1) through the filter decolorization device (B) at 200kg / h, and simultaneously keep the pressure of the bromotrifluoromethane raffinate steel cylinder (A) at about 0.2MPa. The difluorodibromide crude stream (2) obtained after filtering and decolorizing through the filter decolorization device (B) enters the lower body of the No. 1 rectification tower (C) for rectification, and the still temperature of the No. 1 rectification tower (C) is controlled. About 50°C, body temperature about 42°C, top temperature about 33°C, tower pressure about 0.12MPa, and reflux. From the tower top of No. 1 rectifying column (C), obtain the stream (3) that is substantially difluoro-bromomethane and difluoro-chloro-br...

Embodiment 2

[0024] In the bromotrifluoromethane raffinate (1) obtained from the bromotrifluoromethane raffinate steel cylinder (A), the main components include 58% difluorodibromomethane, 31% difluorochlorobromomethane and 3.6% difluorobromomethane. Pass the bromotrifluoromethane raffinate (1) through the filter decolorization device (B) at 250kg / h, and simultaneously keep the pressure of the bromotrifluoromethane raffinate steel cylinder (A) at about 0.2MPa. The difluorodibromide crude stream (2) obtained after filtering and decolorizing through the filter decolorization device (B) enters the lower body of the No. 1 rectification tower (C) for rectification, and the still temperature of the No. 1 rectification tower (C) is controlled. About 55°C, body temperature about 45°C, top temperature about 40°C, tower pressure about 0.17MPa, and reflux. From the tower top of No. 1 rectifying column (C), obtain the stream (3) that is substantially difluoro-bromomethane and difluoro-chloro-bromometh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com