Method for preparing diphenyl carbonate through transesterification

A technology of diphenyl carbonate and dimethyl carbonate is applied in the field of preparing diphenyl carbonate by transesterification, and can solve the problems of heterogeneous catalyst activity, low selectivity, easy deactivation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 9.0gSnCl 2 2H 2 O and 38.1gGa(NO 3 ) 3 Dissolve in 500mL water, add 300mL aqueous solution containing 29.3g anhydrous sodium carbonate to it, collect the obtained precipitate, wash with deionized water 3 times, each time 1000mL, and dry the obtained precipitate in an oven at 120°C for 24 hours , fired at 600°C for 5 hours to obtain SnO 2 / Ga 2 o 3 Mixed oxide catalyst MO-1, in which SnO and Ga 2 o 3 The parts by weight are respectively 30 parts and 70 parts.

Embodiment 2~15

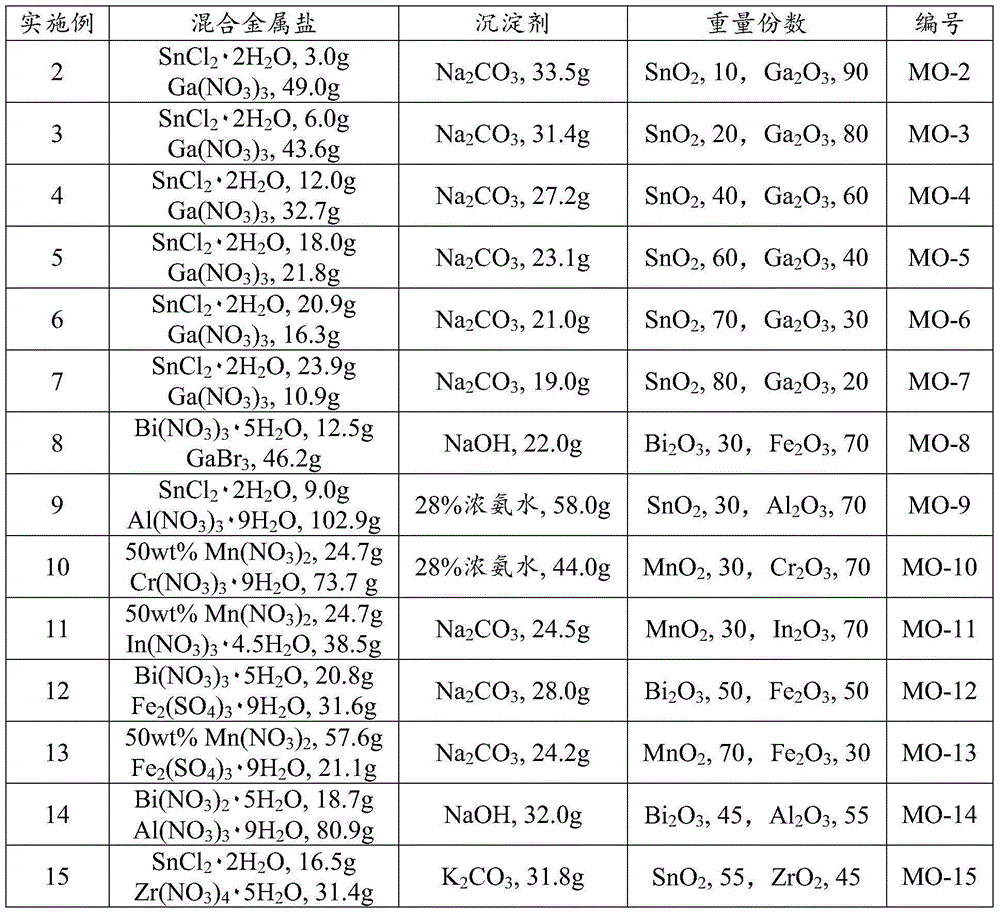

[0022] The mixed metal oxide catalyst obtained is shown in Table 1 by changing the type and amount of mixed metal salts and precipitants used, and keeping the rest of the conditions unchanged.

[0023] Table 1

[0024]

Embodiment 16

[0026] Take by weighing 10g of the MO-1 catalyst prepared by the above [Example 1] and place it in a 300mL stainless steel reactor, add N 2 Replace the air in the reaction kettle, then fill with 50.0g phenyl acetate and 14.1g dimethyl carbonate, heat up to 175°C, cool after 5 hours of reaction, carry out chromatographic analysis to the reaction product, obtain the conversion of dimethyl carbonate (DMC) The yield was 87.9%, the selectivity of diphenyl carbonate (DPC) was 46.5%, and the selectivity of methylphenyl carbonate (MPC) was 52.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com