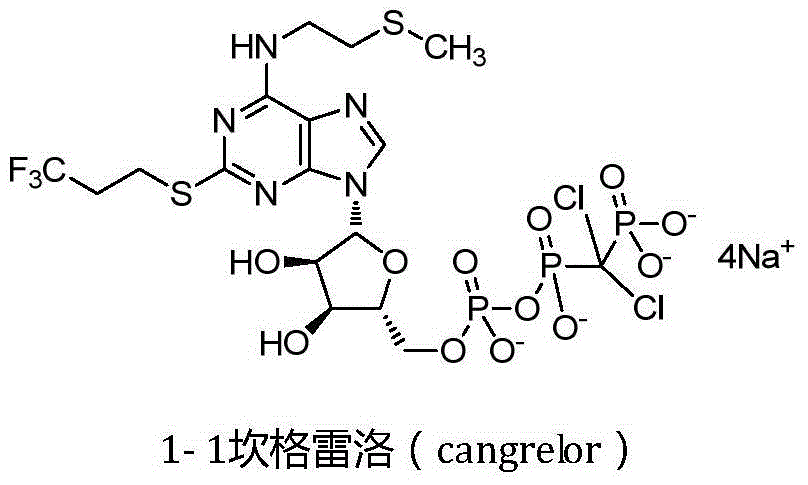

Cangrelor intermediate and preparation method and application thereof

A technology of reaction and reaction solvent, applied in the field of cangrelor preparation, can solve problems such as difficulty in product purification, and achieve the effects of easy operation, high purity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

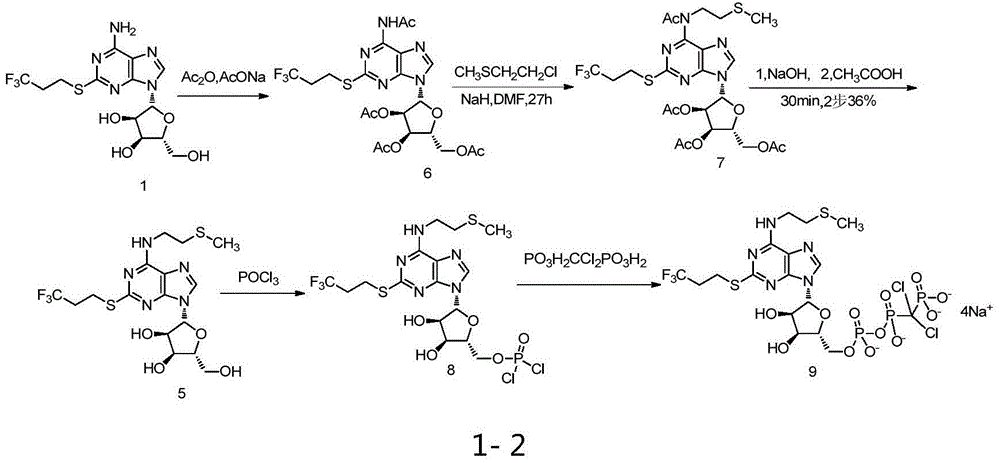

Method used

Image

Examples

Embodiment 1-4

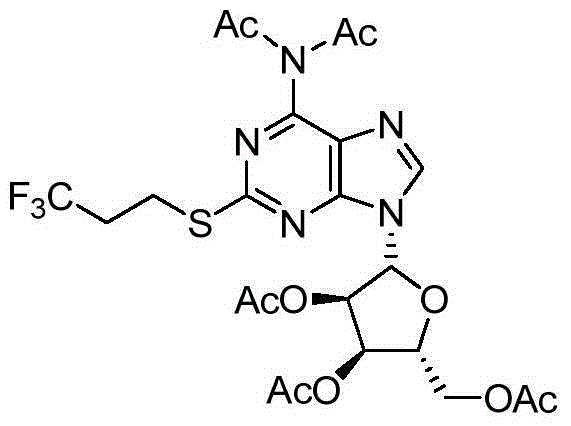

[0033] Example 1-4: Synthesis of 2-[(3,3,3-trifluoropropyl)thio]adenosine-2',3',5'-triethyl ester (2)

[0034] 2-[(3,3,3-trifluoropropyl)thio]adenosine (10.0g, 25.3mmol) was dissolved in pyridine (20ml, 253mmol, 10eq), and acetic anhydride (35ml, 5eq), reacted at -5°C for 3h, added 100ml of water to precipitate a white solid, stirred for 1h and filtered with suction to obtain 11.35g of a white solid, with a yield of 86%. ESI-MS(m / z): 522.13[M+H] + , 544.11[M+Na] + , 560.09[M+K] + ; 1HNMRδ (CDCl 3 ) 7.87 (1H, s, H-8), 6.14 (1H, d, H-1'), 5.82 (1H, t, H-2'), 5.67 (2H, s, NH 2 ), 5.45 (1H, m, H-3'), 4.41 (3H, m, H-4', 5'), 3.29 (2H, m, SCH 2 ),2.63(2H,m,CF 3 CH 2 ), 2.13 (3H, s, CH 3 CO), 2.12 (3H, s, CH 3 CO), 2.07 (3H, s, CH 3 CO).

[0035] Dissolve 2-[(3,3,3-trifluoropropyl)thio]adenosine (5.0g, 12.65mmol) in acetic anhydride (60ml, 632.34mmol, 50eq) to -15°C, add triethyl Amine (3.84g, 3eq), reacted for 7h, added 50ml of water to precipitate a white solid, stirred...

Embodiment 5-8

[0038] Example 5-8 Synthesis of N-formyl-2-[(3,3,3-trifluoropropyl)thio]adenosine-2',3',5'-triacetyl (3)

[0039] Formic acid (13ml, 345mmol, 18eq) was added to acetic anhydride (27ml, 288mmol, 15eq) at low temperature, stirred at 50°C for 30min, cooled to room temperature, compound 2 (10.0g, 19.2mmol) was added, and reacted at 70°C for 3.5h. Add 65ml of water to precipitate a white solid, stir at about 20°C for 2h and filter with suction to obtain compound (3) (9.86g, yield 94.0%). ESI-MS (m / z): 572.15[M+Na] + ; 1HNMRδ (CDCl 3 ) 9.83 (2H, s, NH+CHO), 8.40 (1H, s, H-8), 6.21 (1H, d, H-1'), 5.85 (1H, t, H-2'), 5.56 (1H , t, H-3'), 4.40(3H, 4-H'+5-2H'), 3.32(2H, SCH 2 ), 2.64 (2H, CF 3 -CH 2 ), 2.15-2.07 (6H, CH 3 CO).

[0040] Formic acid (14.47ml, 383.5mmol, 50eq) was added to acetic anhydride (7.25ml, 76.7mmol, 10eq) at low temperature and stirred at 50°C for 30min, lowered to 25°C, compound 2 (4.0g, 7.67mmol) was added, and reacted at 60°C 10h. Add 65ml of water to ...

Embodiment 9-12

[0043] Example 9-12: N-formyl-N-[2-(methylthio)ethyl]-2-[(3,3,3-trifluoropropyl)thio]adenosine-2',3 Synthesis of ',5'-triacetyl(4)

[0044] Dissolve compound 3 (8.0g, 14.6mmol) in 80ml of DMF, then add potassium carbonate (4.02g, 2eq), react at 60°C for 1h, add 2-chloroethyl methyl sulfide (4.35ml, 3eq) and react at 60°C After 2 hours, 8.58 g of dark syrup was obtained, with a yield of 94%. TLC (dichloromethane: methanol = 20:1) R f = 0.9.

[0045] Dissolve compound 3 (5.0g, 9.1mmol) in 50ml of DMF, then add triethylamine (1.3ml, 1eq), react at 60°C for 1h, add 2-chloroethyl methyl sulfide (1.81ml, 2eq) at 25°C After 15 hours of reaction, 3.42 g of dark syrup was obtained, with a yield of 60%.

[0046] Dissolve compound 3 (4.0g, 7.3mmol) in 40ml DMF, add sodium carbonate (1.54g, 2eq), react at 60°C for 1h, add 2-chloroethyl methyl sulfide (2.2ml, 3eq) and react at 60°C After 2 hours, 4.34 g of dark syrup was obtained, with a yield of 95%.

[0047] Dissolve compound 3 (4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com