Viscous-elastic particle oil-displacing agent with fluorescence characteristic and preparation method therefor

A technology of fluorescent properties and oil-displacing agents, applied in chemical instruments and methods, luminescent materials, drilling compositions, etc., can solve the problems of complex polymerization process, difficulty in obtaining, and difficulty in industrial production, and achieve simple post-processing of products , short polymerization cycle, excellent heat resistance, salt resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

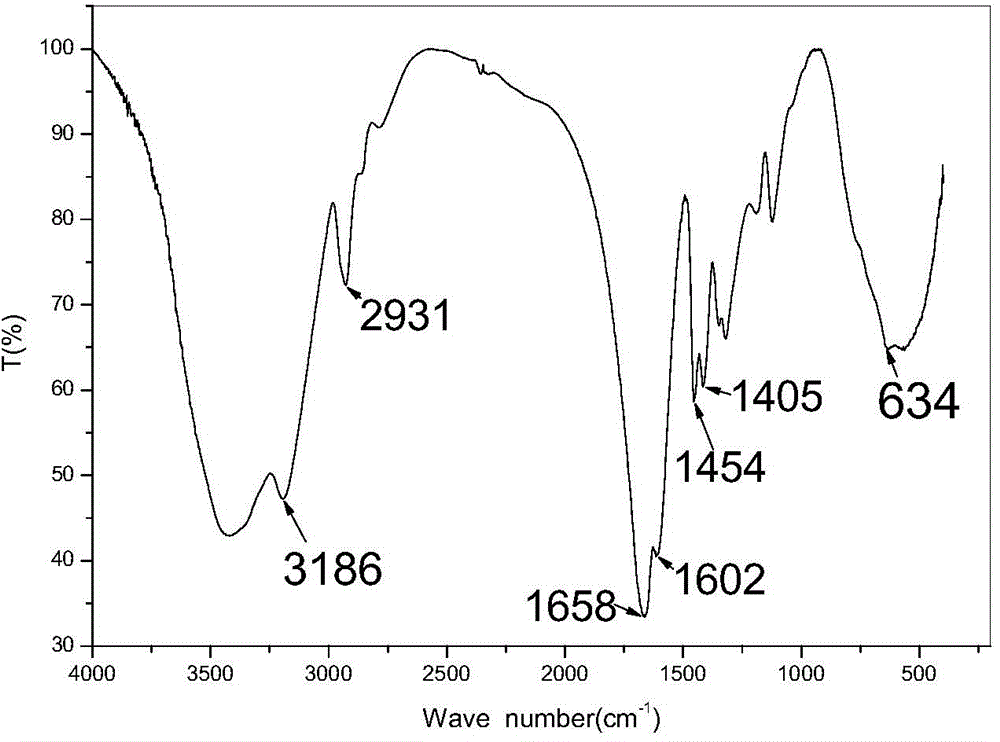

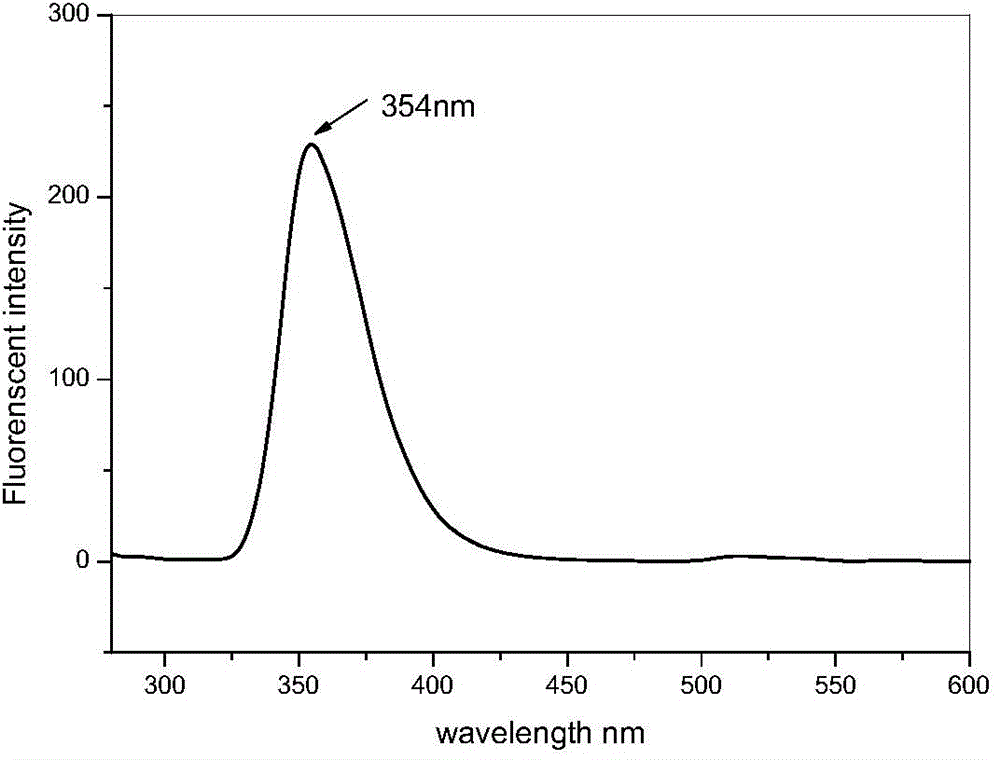

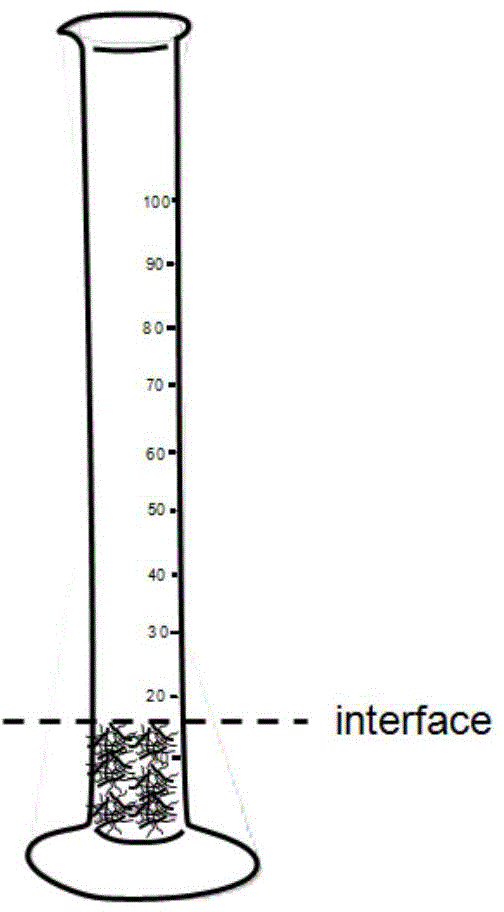

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 100g of acrylamide in 260g of water to make a solution, dissolve 0.45g of dimethylaminoethyl methacrylate in 50g of water to make a solution, dissolve 0.0005g of N‐vinylcarbazole in 1g of ethanol to make a solution, and add them in turn to three necks bottle, and placed in a water bath at 20°C; after passing nitrogen gas for 20 minutes, add a solution prepared by dissolving 0.02g of potassium persulfate in 40g of water into the three-necked flask. After the temperature rise of the reaction solution is greater than 1°C, stop the nitrogen flow. After the reaction, put the three-neck bottle in a 75°C water bath to keep warm for 5 hours, then take out the gel, cut it into pieces, dry, crush, and sieve it. Powdered product available.

Embodiment 2

[0022] Dissolve 100g of acrylamide in 290g of water to make a solution, dissolve 0.5g of dimethylaminoethyl methacrylate in 60g of water to make a solution, dissolve 0.0004g of N‐vinylcarbazole in 0.2g of ethanol to make a solution, add three Neck bottle, and placed in a water bath at 15 ° C; after 20 minutes of nitrogen, 0.035g of potassium persulfate dissolved in 40g of water into the three-necked bottle. After the temperature rise of the reaction solution is greater than 1°C, stop the nitrogen flow. After the reaction, put the three-neck bottle into an 80°C water bath to keep warm for 4 hours, then take out the gel, cut it into pieces, dry it, crush it, and sieve it. Powdered product available.

Embodiment 3

[0024] Dissolve 100g of acrylamide in 250g of water to make a solution, dissolve 0.3g of dimethylaminoethyl methacrylate in 40g of water to make a solution, dissolve 0.025g of N‐vinylcarbazole in 4g of ethanol to make a solution, and add three necks in sequence bottle, and placed in a water bath at 25°C; after passing through nitrogen for 20 minutes, add a solution prepared by dissolving 0.015g of potassium persulfate in 20g of water into the three-necked flask. After the temperature rise of the reaction solution is greater than 1°C, stop the nitrogen flow. After the reaction, put the three-neck bottle in a water bath at 85°C to keep warm for 3 hours, then take out the gel, cut it into pieces, dry it, crush it, and sieve it. Powdered product available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com