Computer simulation prediction method of in-car vibration and noise of car

A technology of computer simulation and prediction method, which is applied in calculation, special data processing applications, instruments, etc., can solve problems that cannot be predicted, cannot be rectified, and unfavorable analysis problems, so as to achieve good practicability, save a lot of cost, and shorten the development cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The computer simulation prediction method of the automobile interior vibration and noise of the present embodiment comprises the following steps:

[0036] A: Calculate the reciprocating inertial force and reciprocating moment of inertia of the crank mechanism of the engine; the inertial force of the crank mechanism of the engine when it is in motion and moments of inertia They are:

[0037] ;

[0038] ;

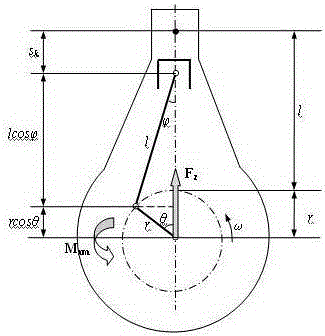

[0039] Among them, the connecting rod ratio ,and is the reciprocating mass of the crank mechanism. is the angular displacement of the crank, is the angular velocity of the crank, is the crank radius, is the connecting rod length (see figure 1 label).

[0040] reciprocating inertial force and reciprocating moment of inertia It can be calculated in the engine dynamics analysis software.

[0041] B: Calculate the torque generated by the gas pressure according to the combustion pressure of the engine, and the torque is:

[0042] ;

[0043] in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com