Directly-heating type expansion high-pressure synthesis equipment

A high-pressure synthesis, direct-heating technology, applied in the direction of pressure vessels used in chemical processes, can solve the problems of the six-sided top press being unable to compress infinitely, the thermal compression stroke is small, and the investment cost is increased, and the temperature and pressure are controllable. Good, less heat loss, lower investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

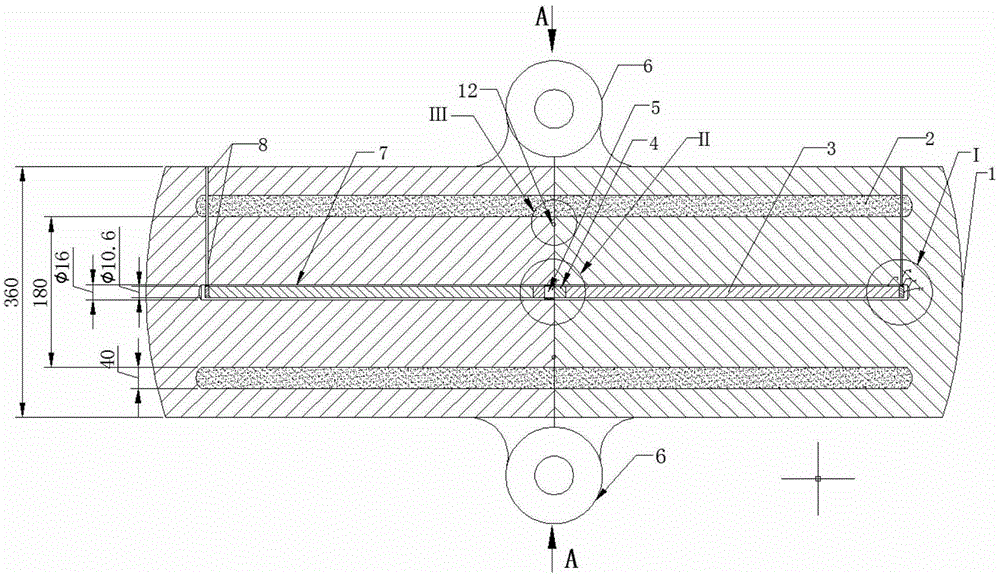

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

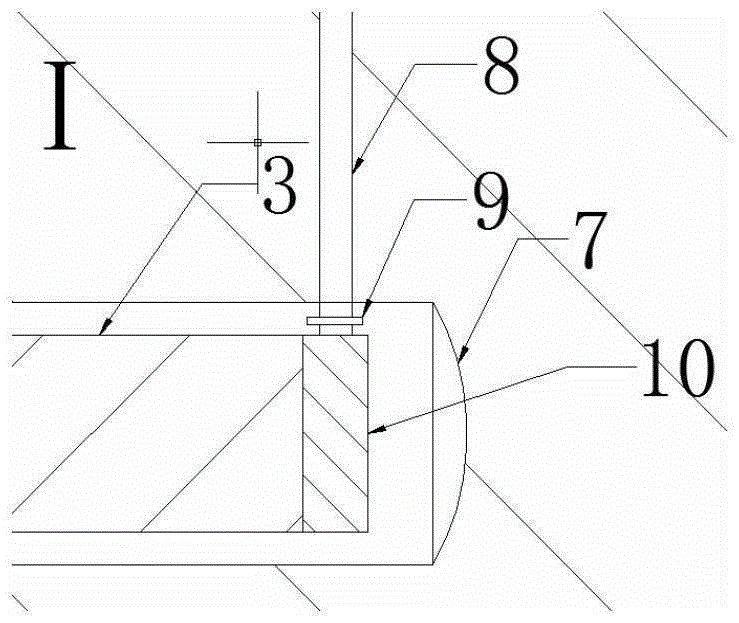

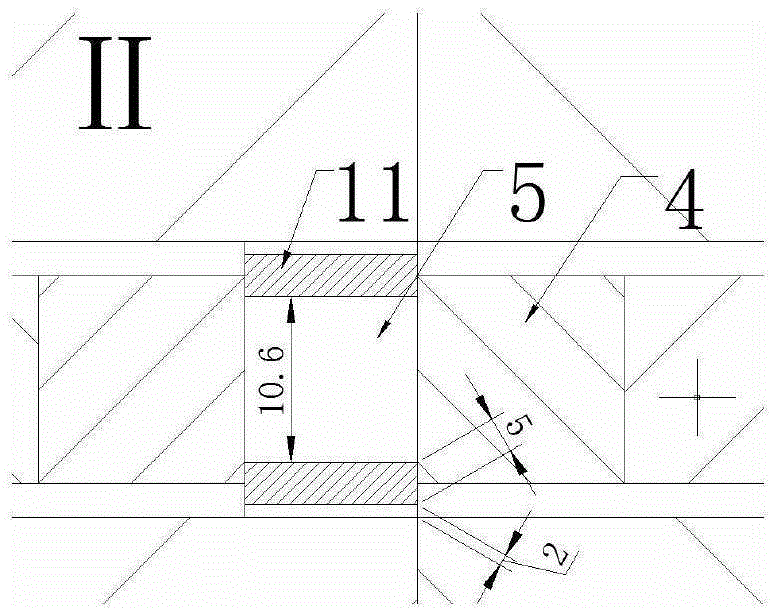

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7 As shown, the direct thermal expansion high-pressure synthesis equipment includes a high-strength alloy steel cylinder 1, a heat insulating material layer 2, a high-pressure column 3, a hard alloy block 4, a sample synthesis chamber 5, a hinge fastening link device 6, ceramic Insulating tube 7, wire channel 8, wire connection fastening device 9, end hard alloy 10, metal heating ring 11, sealing ring 12, etc.

[0033] The insulating material layer 2 is located in the alloy steel cylinder body 1 , and the ceramic insulating tube 7 is located in the center of the alloy steel cylinder body 1 and also in the package of the insulating material layer 2 . The high-voltage column 3 is located in the ceramic insulating tube 7, the high-voltage column 3 is disconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com