Automatic lifting plate shearing machine of back stop device and assembling and using method of automatic lifting plate shearing machine

A technology of automatic lifting and assembling method, applied in shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve the problems of large space occupation, low lifting safety and poor reliability of the back gauge device, and achieve easy Ingenious layout, structural design and responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

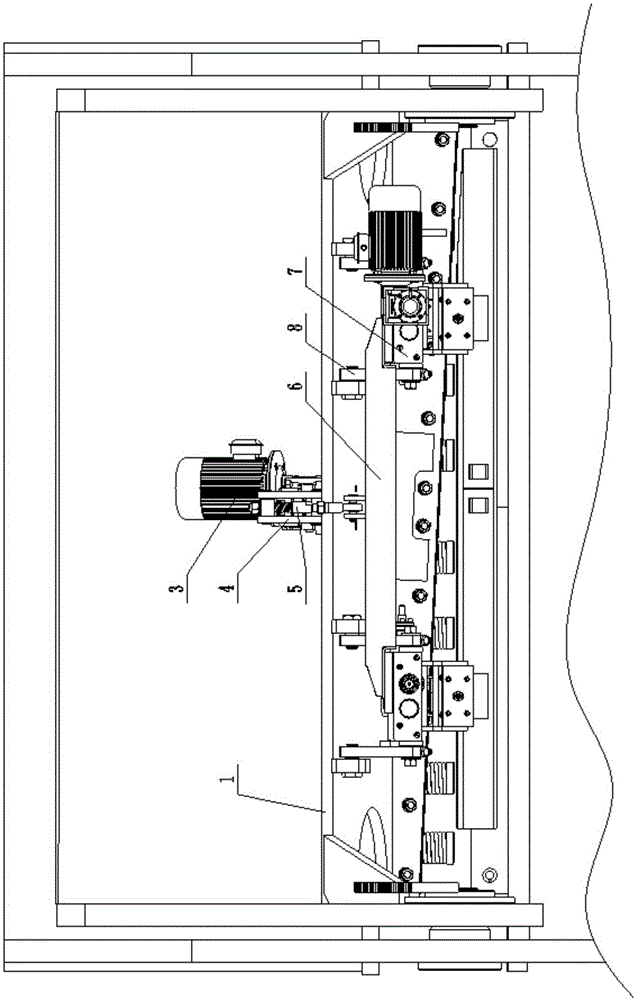

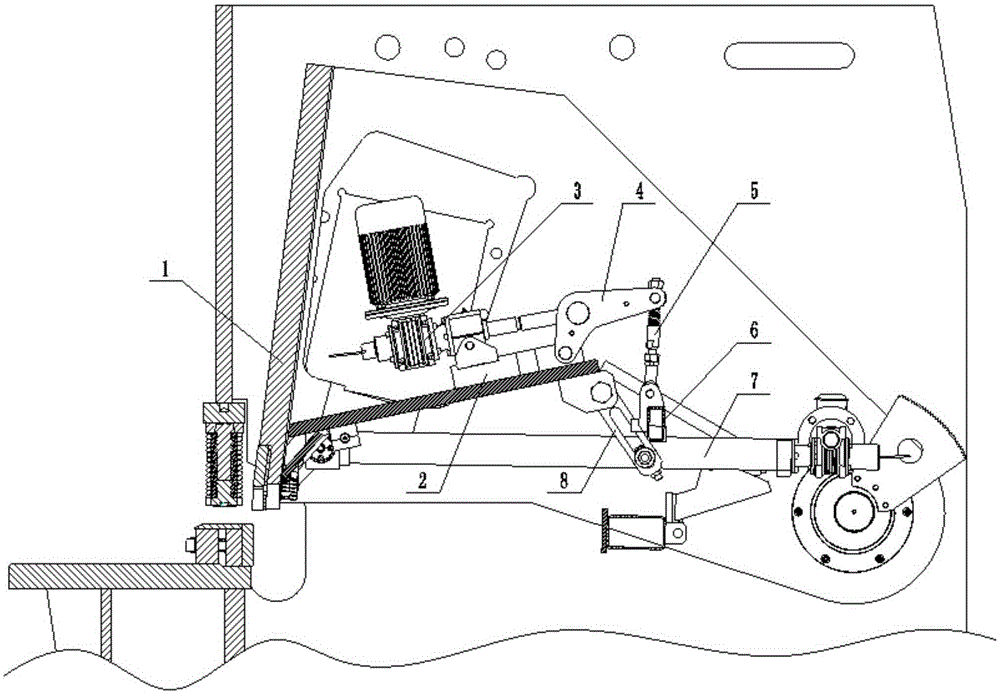

[0041] Such as figure 1 with figure 2 As shown, a shearing machine with a back gauge device in this embodiment that can be automatically raised and lowered includes a tool holder 1 , a back gauge device 7 , a pull rod device 5 , a connecting beam 6 and a material stop hanging plate 8 . Wherein, the rear side of the knife rest 1 is provided with an inclined support plate; one end of the support plate is connected to the lower part of the rear side of the knife rest 1, and a base 2 is arranged above the other end of the support plate. The base 2 is provided with a driving device 3 , and the front end of the base 2 is hinged with a rocker 4 .

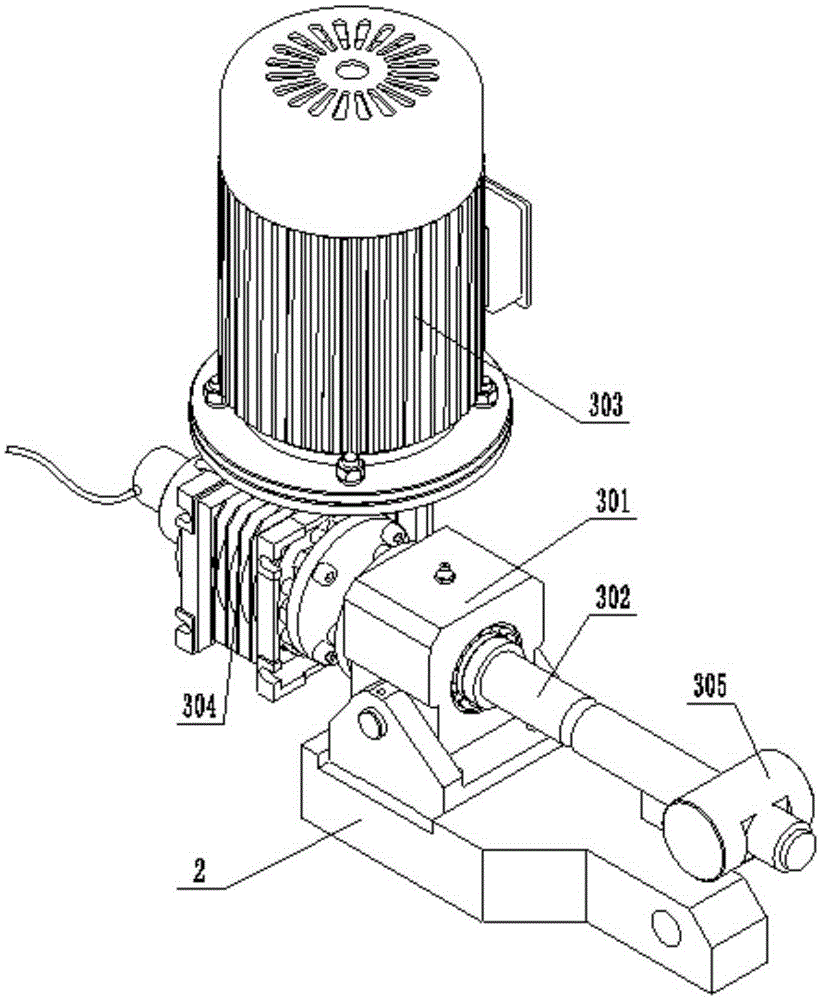

[0042] combine image 3 , the drive device 3 includes a bearing seat 301 hinged on the base 2, a drive shaft 302, a motor 303 and a reducer 304. The drive shaft 302 is connected to the bearing seat 301 through a bearing, and one end of the drive shaft 302 is threaded with a first pin shaft 305, the first pin shaft 305 is hinged with th...

Embodiment 2

[0055] In this embodiment, a shearing machine with a back gauge device that can be automatically raised and lowered has the same structure as that in Embodiment 1.

[0056] In this embodiment, record the linear distance from the hinge point of the first pin shaft 305 and the rocker arm member 4 to the hinge point of the rocker arm member 4 and the base 2 as L1, and the connection point between the pull rod device 5 and the rocker arm member 4 The linear distance between the arm 4 and the hinge point of the base 2 is L2, and L1:L2=1:3.

[0057] The above-mentioned method for assembling a shearing machine with a backgauge device that can be automatically raised and lowered, the steps are:

[0058] 1) Install the support plate to the knife rest 1, and install the knife rest 1 on the shearing machine;

[0059] 2) Firstly connect the front end of the back gauge device 7 to the support plate, and then connect the material hanger plate 8 to the support plate and the back gauge devic...

Embodiment 3

[0066] The structure and assembly method of a shearing machine with automatic lifting of the back gauge device in this embodiment are the same as those in Embodiment 1.

[0067] In this embodiment, record the linear distance from the hinge point of the first pin shaft 305 and the rocker arm member 4 to the hinge point of the rocker arm member 4 and the base 2 as L1, and the connection point between the pull rod device 5 and the rocker arm member 4 The linear distance between the hinge point of the arm 4 and the base 2 is L2, and L1:L2=1:2.7.

[0068] When using the above-mentioned shearing machine with automatic lifting of the rear gauge device, first turn the adjusting nut to adjust the pre-compression of the spring 504 to λ, λ=βF / k, where β is 0.9-1.2, F Be 1-1.4KN, k is the elastic coefficient of spring 504, in the present embodiment, get β=1.2, F=1.4KN, k=1.5*10 5 N / m, then λ=11.2cm; Then start the motor 303, and control the rotating speed of the drive shaft 302 to be 253...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com