A parallel macro-micro high-precision motion platform

A motion platform, high-precision technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of weak bearing capacity and low natural frequency, and achieve the effect of large bearing capacity, excellent dynamic characteristics, and no accumulation of motion errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

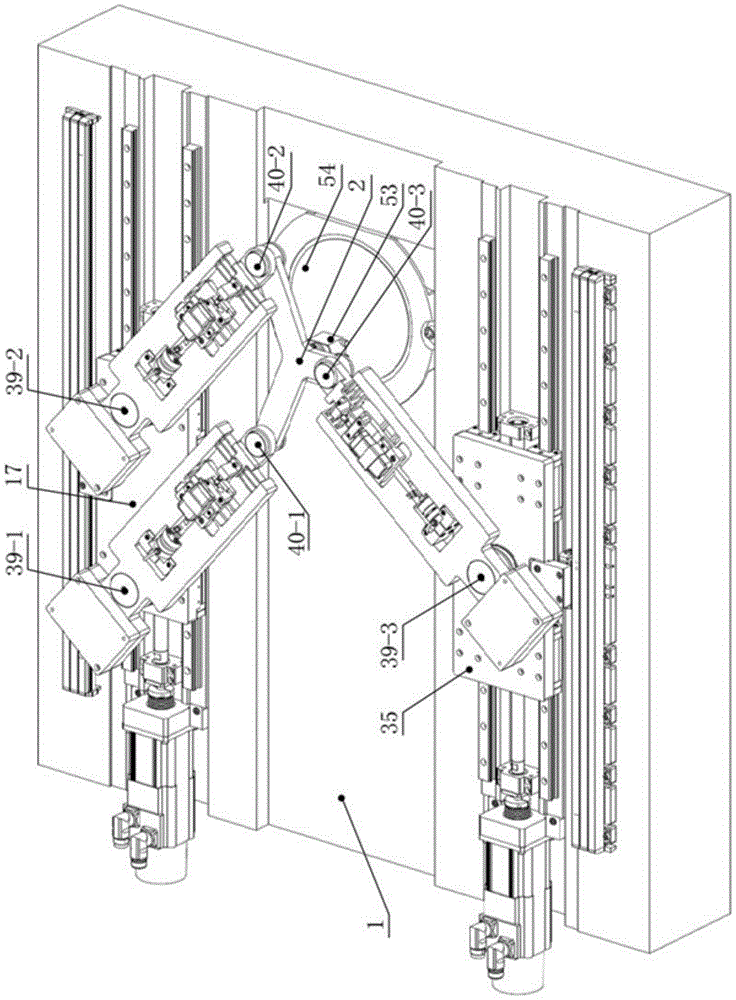

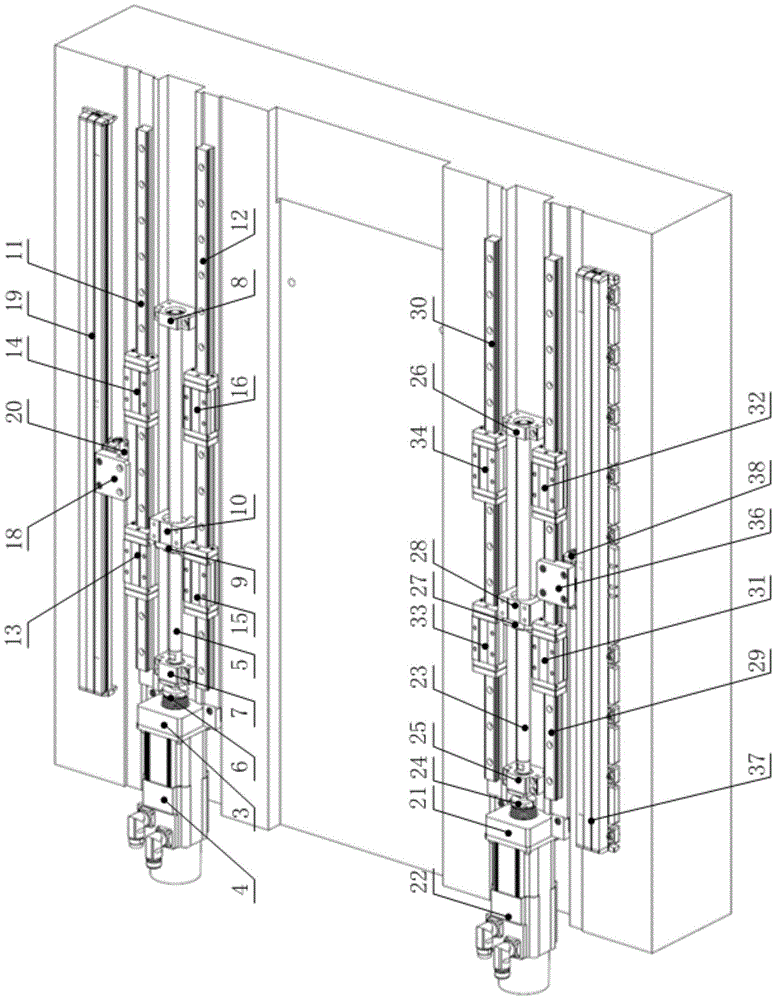

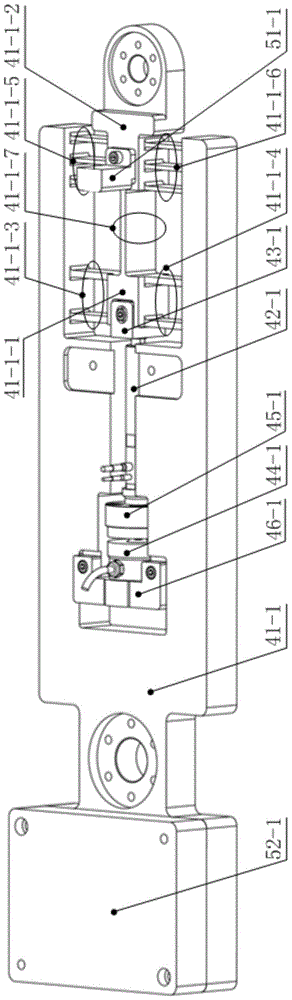

[0024] figure 1 It is a novel parallel macro-micro high-precision motion platform of the present invention, figure 2 It is a structural schematic diagram of the linear drive system of the present invention, as figure 1 with 2 As shown, the first linear feed system is arranged on the left side of the base 1; the first servo motor support seat 3 is fixed on the left side of the base 1; the first servo motor 4 is fixedly installed on the first servo motor support on the seat 3; the first ball screw 5 is connected to the rotating shaft of the first servo motor 4 through the first coupling 6; the first ball screw 5 is fixed on the base 1 at the end close to the first coupling 6 The first ball screw on the fixed support base 7 is supported and rotated, and the other end of the first ball screw 5 is supported and rotated by the first ball screw floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com