Method and equipment for recognizing bar codes of inner layers of circuit boards and printing codes on outer layers of circuit boards

A circuit board and barcode technology, applied in the field of circuit board identification, can solve problems such as scrapping, mixing circuit boards into other batches, and wrong operation by workers, and achieve the effect of simple equipment operation, improved production management level, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe in detail the structural features, technical means, and achieved goals and effects of the present invention, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

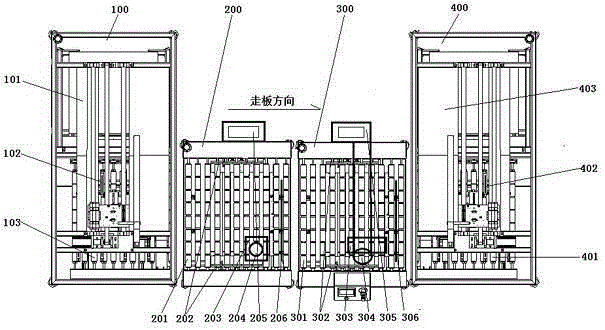

[0014] The equipment that recognizes the barcode on the inner layer of the circuit board and prints the code on the outer layer is mainly composed of a board feeding unit 100 , an X-ray inspection machine 200 , a laser coding host 300 and a board receiving unit 400 arranged in sequence.

[0015] The board feeding unit 100 includes a board placement platform 101 to be coded, a board feeding motion mechanism 102 and a board feeding roller group 103, and the board feeding motion mechanism 102 moves back and forth above the board placement platform 101 and the board feeding roller group 103.

[0016] The board receiving unit 400 includes a coded board placement platform 403, a board receiving motion mechanism 402 and a board receiving roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com